When you think about oil and gas production, the process of separating the raw wellstream into usable components might be the first thing that comes to mind. Yet, it’s a critical step that ensures efficient handling of hydrocarbons. That’s where three-phase separators come in, a critical piece of equipment in the oil and gas industry. These vessels are critical in ensuring that crude oil, natural gas, and water are efficiently separated, paving the way for further processing. In this blog, we’ll break down what three-phase separators are, how they work, their types, and why they’re vital in the process industry.

What Are Three-Phase Separators?

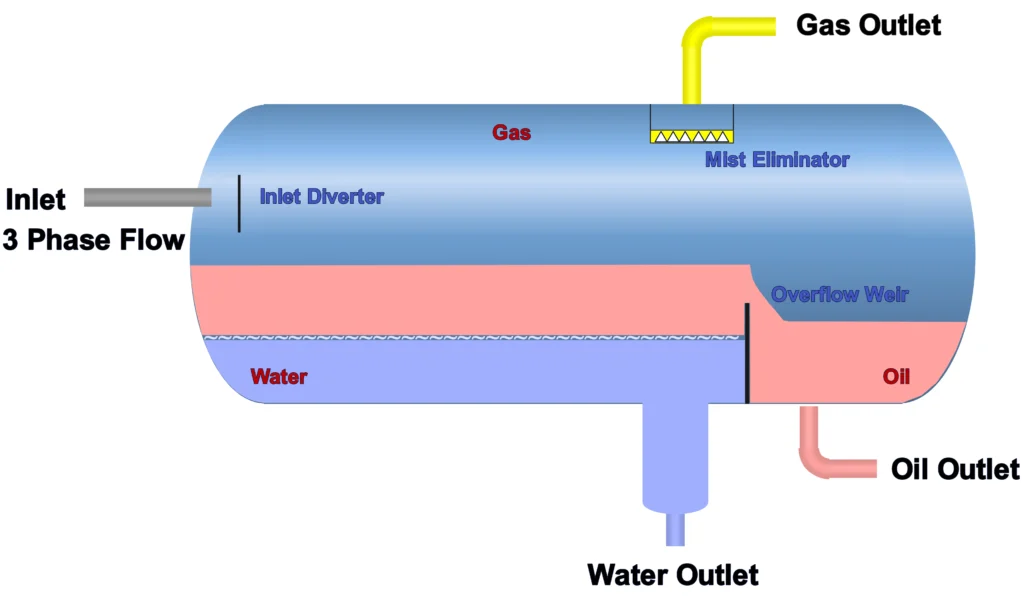

Three-phase separators are specialized pressure vessels that separate a wellstream into its three core components: gas, oil and water. Unlike two-phase separators, which only split gas from liquid, three-phase separators tackle the added challenge of separating free water from hydrocarbons. They’re essential in oilfields where wells produce significant water alongside oil and gas, often found at wellheads, gasoline plants, or gas transmission lines.

Their primary goal is to deliver clean separation, directing gas to pipelines, oil to storage, and water to treatment or disposal systems. This prevents downstream issues like equipment damage, product contamination, or environmental violations, making them vital for operational efficiency and compliance with standards like OSHA.

How Do Three-Phase Separators Work?

The brilliance of three-phase separators lies in their use of physical principles like gravity and density differences to sort out a complex wellstream. Here’s how they do it:

- Inlet and Initial Separation: The wellstream enters through a centrifugal inlet device or diverter, which spins the mixture to create forces up to 500 times gravity. This flings heavier liquids (oil and water) outward, separating them from the lighter gas, which rises while liquids drop to the vessel’s bottom.

- Gravity Settling Section: In the settling section, liquids collect and stratify based on density, water sinks below oil, forming an oil pad on top. A spacious settling area minimizes turbulence, allowing clear separation. Some designs use a down-comer to direct liquids below the oil-water interface, enhancing water droplet coalescence.

- Mist Eliminator: As gas moves toward the outlet, it passes through a mist eliminator (like a stainless-steel wire mesh or vane pack). This captures tiny liquid droplets (down to 10 microns), coalescing them into larger drops that fall back into the liquid section, ensuring the gas is nearly 99.9% dry.

- Controls and Valves: Two liquid level controllers, one for oil, one for water, paired with dump valves manage the discharge of each liquid phase. A gas back pressure valve regulates vessel pressure, while safety relief valves and gauges ensure safe operation.

This process minimizes carryover, ensuring gas, oil, and water are cleanly separated for their next steps.

Key Functions of Three-Phase Separators

- Gas Separation: Removes gas from the liquid phases to prevent turbulence and ensure efficient processing.

- Oil-Water Separation: Separates free water from oil, allowing each to be processed or disposed of separately.

- Liquid Retention: Provides sufficient time for gas to break out of the liquid and for oil and water to segregate based on density differences.

These separators are commonly found between the wellhead and the pipeline, ensuring that each phase is ready for downstream handling.

Types of Three-Phase Separators

Three-phase separators come in different designs, each with specific operational needs. The main types are:

Horizontal Three-Phase Separators

These elongated vessels excel in high-pressure wells with high gas-oil ratios. They offer a large gas-liquid interface for efficient gravity separation and are easier to skid-mount for field use. Features like weirs or bucket-and-weir designs maintain oil and water levels, though liquid level control is critical due to limited surge space.

Advantages:

- More efficient gravity separation due to larger interface areas.

- Better for handling emulsions or foam at the gas-oil interface.

Drawbacks:

- Less effective at handling solids, which can accumulate and require multiple drains.

- Requires more plan area, which can be a constraint offshore.

Vertical Three-Phase Separators

Tall and cylindrical, these are ideal for low gas-oil ratio wells or streams with high liquid volumes. Their design provides more surge capacity, reducing liquid carryover into the gas stream, and they handle solids better, with dump valves at the bottom. However, they’re costlier to fabricate and transport.

Advantages:

- Better at handling solids, as the liquid dump valve can be placed at the bottom center.

- Requires less plan area, making them ideal for offshore platforms.

Drawbacks:

- Less efficient gravity separation compared to horizontal vessels.

- Maintenance of controls or relief valves may require ladders or platforms.

Free-Water Knockout (FWKO)

A specialized separator for streams with minimal gas, focusing on oil-water separation. Operated as packed vessels, they use interface level controllers and have only oil and water outlets.

Flow Splitter

A variation of the FWKO, this splits the oil outlet into multiple streams for different downstream processes, using adjustable weirs and a gas blanket for proportional distribution.

Spherical separators are less common for three-phase operations due to limited space for proper liquid settling and baffling.

Factors Affecting Separator Performance

Several variables influence how effectively a three-phase separator performs:

- Operating Pressure: Higher pressures increase liquid recovery by keeping hydrocarbons in the liquid phase. Operators adjust pressure using back pressure valves, limited by well flow and pipeline requirements.

- Operating Temperature: Lower temperatures enhance liquid recovery by reducing vaporization. Overheating (e.g., via indirect heaters) can reduce liquid yields, so precise temperature control is key.

- Fluid Stream Composition: The natural mix of gas, oil, and water varies by well. Understanding this composition helps optimize separator settings for maximum recovery, especially for high-API gravity condensate or heavy crude.

Setting properly these factors through trial-and-error or calculations like flash vaporization maximizes liquid recovery while meeting pipeline gas quality standards.

Retention Time for Three-Phase Separators

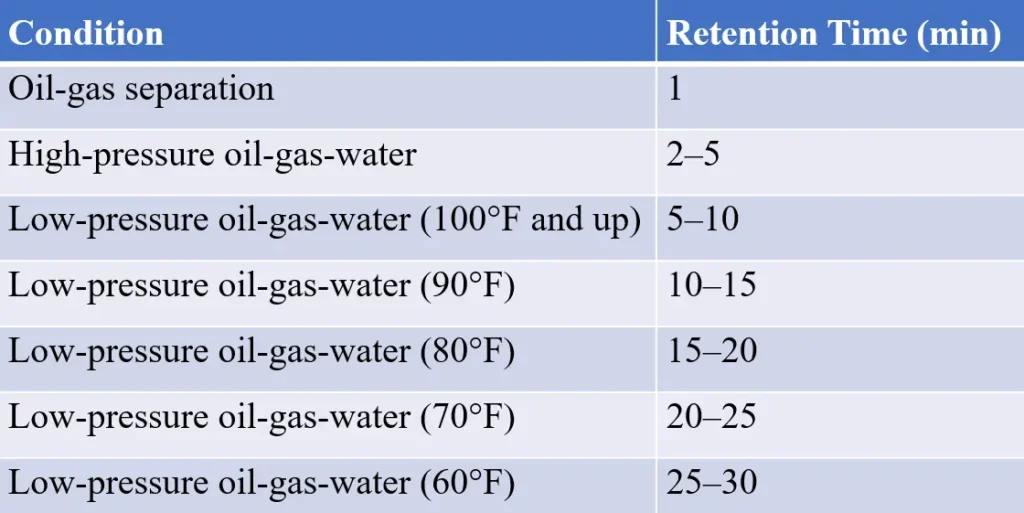

Retention time is the time liquids need to reach equilibrium in the separator.

For three-phase separators, retention times typically range from 2–5 minutes for high-pressure wells and 5–30 minutes for low-pressure wells, depending on temperature.

Why Three-Phase Separators Matter

Three-phase separators are critical for:

- Safety: Preventing gas blowby or liquid carryover protects downstream equipment like compressors from damage and reduces risks of hazardous releases.

- Efficiency: Clean separation ensures high-quality oil output, minimizes waste, and optimizes hydrocarbon recovery.

- Compliance: Proper water separation aligns with environmental regulations and OSHA standards for safe fluid handling.

- Environmental Protection: Effective water removal reduces the risk of spills or improper disposal, supporting sustainable operations.

For process safety engineers and operators, mastering these separators ensures smooth, compliant, and profitable operations.

Common Challenges and Solutions

- Emulsions: Emulsions at the oil-water interface hinder separation. Adding heat or de-emulsifying chemicals can break them down.

- Solids Handling: Horizontal separators struggle with solids accumulation, requiring frequent draining. Vertical designs are better for solids-heavy streams.

- Foam: Foam at the gas-oil interface disrupts separation. Coalescing plates or turbulent flow coalescers help, though they may clog with sand or paraffin.

People Also Asked Questions with Answers

What’s the difference between two-phase and three-phase separators?

Two-phase separators split gas from liquid (oil or water), while three-phase separators further separate the liquid into oil and water, requiring additional controls like interface level controllers or weirs.

What are the advantages of horizontal vs. vertical separators?

Horizontal separators offer larger interface areas for better gravity separation and handle emulsions well, while vertical separators excel at solids handling and require less plan area, ideal for offshore use.

How does corrosion affect three-phase separators?

Corrosion from gases like H₂S or CO₂ can weaken vessels, risking leaks or failures. Protection includes corrosion allowances, internal coatings, sacrificial anodes, and post-weld heat treatment.

Why is retention time important?

Retention time ensures liquids settle properly, reaching equilibrium to avoid carryover or unstable products. It varies with temperature and pressure.

References

- Sivalls, C. Richard. Oil and Gas Separation Design Manual, Sivalls, Inc., 2009.

- API Specification 12J, Seventh Edition, October 1989, American Petroleum Institute.

- Arnold, K. Surface Production Operations. (Document provided)

- Sivalls, C. Richard, Glycol Dehydration Design Manual, Gas Conditioning Conference, University of Oklahoma, 1974.

- https://www.sciencedirect.com

- https://chemicalengineeringworld.com