The Hydrotreating process is critical for oil refineries to produce low sulfur petroleum products and meet strict quality and environmental standards. The major issue with the Hydroprocessing unit operation is fouling which causes a pressure drop across the catalyst bed and shortens its cycle length. Fouling imposes irreversible effects on the activity of the hydrotreating catalyst, once the catalyst has been poisoned with these agents it can not be regenerated. Then the only option left for the refiner is to replace the affected catalyst through skimming.

Moreover, the unplanned shutdown of the unit is expensive for the refiner in terms of the catalyst, manpower costs, production loss, and restricted overall refinery operation. For more solutions to high differential pressure across the hydrotreating reactors, please view my other blogs;

- Troubleshooting of hydrotreating Reactors

- Grading or guard bed catalyst

- Effects of metals on hydrotreating catalysts

- Hydrotreating Reactor Internals

- Reducing Coke Formation in Hydrotreating Reactors

Fouling agents deposit at the pore entrances or the outer surface of the catalyst and reduce the void space of the catalyst. This deposition creates a layer affecting the accessibility to the catalyst interior and active sites, thus reducing active sites and increasing pressure drop across the hydrotreating reactor.

These fouling components enter the feedstock of the Hydrotreating unit from different sources;

1. Crude oil metals like Pb, Fe, Ni, V, As, Na, Ca, Mg, etc.

2. Iron contamination from Corrosion Products produced in the upstream piping and equipment.

3. Scales, particulates, carbon, and catalyst dust from the upstream units.

4. Some metals like Si and P may come in the feed due to the use of Additives like anti-foaming or corrosion inhibitors at the upstream units.

5. The Olefins, Diolefins, and Asphaltenes react with the catalyst and deposit on its surface.

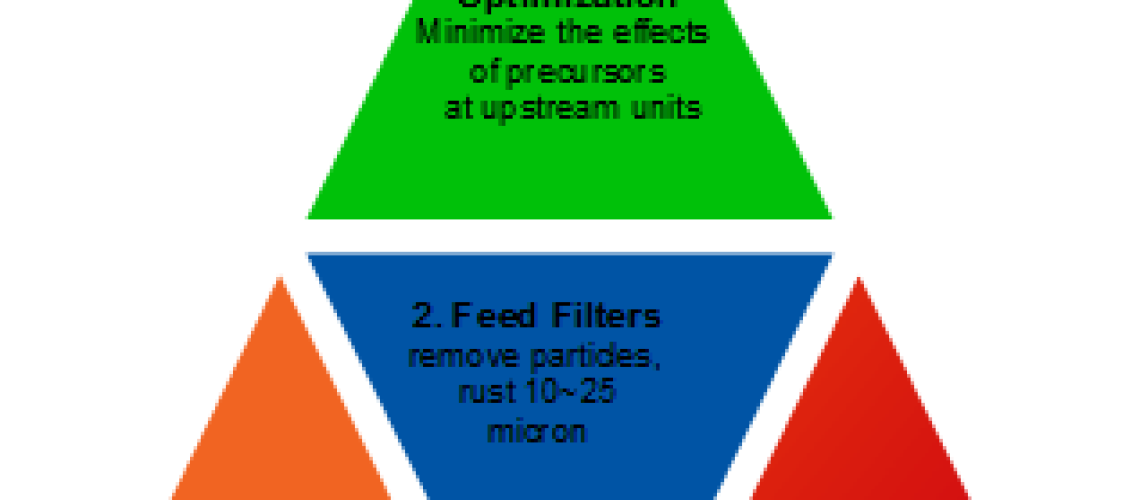

Several methods and techniques have been developed over the years to prevent the accumulation of particles in the catalyst bed of the reactor and to avoid the premature shutdown of the unit due to high-pressure drops. To adopt any kind of solution feedstock should be critically analyzed to find the quantity, severity, variation, and types of all fouling agents. From the given techniques a combination or a single one can be applied depending on the feed quality.

- Optimized Process Operation at upstream units can lower the severity of fouling, for example, in the case of the Diesel Hydrotreating unit, use and in-time cleaning of proper size strainers at diesel supply and diesel circulating pump can remove metals, and efficient operation of the De-Salter at the crude unit will minimize the passing of salts. Moreover, try to cut down heavy feed share and find alternative blending routes keeping in mind the financial aspect. Furthermore, minimize or replace the use of Si or P additives. Likewise, list down and control all the parameters which are affecting the hydrotreating unit.

- Feed Filters are the first line of defense and remove a substantial amount of scales, rust, and solid particles from the feed. But there is a practical limit that below the size of the filter cartridge all the particles will pass to the reactor. Normally, a 10~25 micron size feed filtration system is applied in a typical hydroprocessing plant. Feed filters may be equipped with auto backwash or manual cleaning methods. Any option depends upon the feed types and severity of the feed impurities. Many companies provide feed filtration solutions which include Pall Corporation, Fuji Filters, JONNELS Systems filtration group, etc.

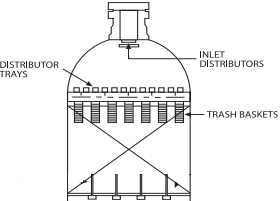

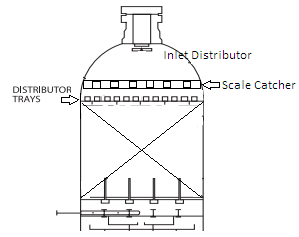

- Mechanical traps like Scale Catcher or Trash Baskets can be installed inside the reactor to remove scales, rust, metals, coke, and other inorganic heavy particles from the reactor feed. Trash baskets are considered to be an old technique but still working in some plants around the world. They are installed at the top of the catalyst bed such that they extend some distance in the catalyst bed. On the other hand, scale catchers developed by Haldor Topsoe are modern, compact, and installed in free space above the top distribution tray in the reactor. It can perform an excellent job with a combination of grading material and feed filters. Haldor Topsoe claims that they have the best scale catchers and their technology is mature in providing these types of mechanical traps.

Fig. 01: Trash Bins

Fig.02: Scale Catcher

4. Grading Catalysts Grading and guard bed catalysts are the macro-porous, grading material at the inlet of the hydrotreating reactor to remove fouling agents and save the main reactive hydrotreating catalyst from fouling and poisoning. The grading and guard bed system works as a filtration system and reduces the pressure drop across the hydrotreating reactor. The grading bed helps, avoiding an unplanned shutdown and increasing catalyst cycle length.

A properly designed grading bed is highly effective when applied with an appropriate feed filtration system or mechanical scale catcher. Grading materials are designed for the removal of specific elements like Ni, V, Si, Fe, etc. but can also stop other contaminants. They have moderate hydrogenation activity, making them appropriate for application with reactive feedstocks such as Di-Olefins and asphaltenes.

For further study also view this blog “Mitigating Hydroprocessing Reactor Fouling”.

For comments, discussion, and questions, comment in the box below or contact at admin@thpetrosolutions.com.

9 thoughts on “Solving Fouling Problems of Hydrotreating Reactor”

Quiet comprehensive and helpful blog this is. Learned many new things. Thanks for that.

Nice effort but plz keep it short form or in form of points

Good information.

Sir i think Si is not in antifoam these may be alcoholic, please guide.

Si (Silicon) is mainly anti foam based , you can see this on this article, https://grace.com/catalysts-and-fuels/en-us/Documents/104SE-Feed%20Contaminants%20in%20Hydroprocessing%20Units.pdf