Successful troubleshooting of the hydrotreating reactor or hydrocracking reactor is necessary for the continued and reliable operation of the unit. The unsatisfactory performance of the hydrotreating reactor not only will disturb the diesel pool but also the whole refinery operation will be at risk. Troubleshooting hydrotreater reactor performance needs a systematic approach. At first, any abnormality in any of the key operating conditions must be identified then corrective actions should be applied to avoid its re-occurrence. The common problems related to hydrotreating reactor performance are temperature and pressure rise across the reactor bed, channelling or mal-distribution of process fluid over the catalyst bed, and high coke rate over the catalyst bed.

For the best performance of a hydrotreating reactor, it is suggested to anticipate all the risks and emergencies in advance and prepare standard instructions to respond in the event of a problem. Further, all the standard operating procedures and instructions must be in line with the vendor guidelines. Following are some common problems related to the hydrotreating reactor and their guidelines based on practical experience for troubleshooting.

1. Thermal runaway across the catalyst beds

Temperature runaway in the reactor bed is the process of sudden and uncontrolled temperature rise during the operation of the catalytic reactor due to uncontrolled exothermic reactions, abnormal firing in the feed heater, unexpected flow reduction in one of the feed streams, changes in feed composition and quench gas failure. Removing one of the feed liquids or gas will stop the exothermic reaction. For quick removal of the feed from the catalyst is the activation of a manual or auto emergency depressurization system. The possible consequence of thermal runaway is the carbon lay down over the catalyst and in extreme cases may damage the hydrotreating catalyst. For more details about temperature runaway, please view the blog “Avoiding Temperature Runaway in Hydroprocessing Reactors”

Causes of Thermal Runaway in Hydrotreating Reactor and its Controls

a. The uncontrolled firing of the feed heater

Check the function of the fuel gas controller and reduce the firing rate if you find any temperature rise at the reactor inlet. This can be done by taking the controller in manual mode or using any other appropriate method to control the firing rate. If the heater firing is not under control, then shut down the heater to avoid a reactor temperature increase.

b. Sudden flow reduction of any of the combined feeds

Sudden flow reduction of gas or liquid will increase the temperature at the reactor bed and in extreme cases may lead to uncontrolled temperature rise. Always, while reducing the feed rate, first decrease the temperature of the reactor and then reduce the feed.

c. Compressor Capacity Change

Change compressor capacity in small steps so that gas flow towards feed passes and quench gas does not reduce abnormally. For example, in the case of a reciprocating recycle gas compressor, when you have to reduce the compressor load from 100 % to 75 %, then take the first action from 100 to 90 %, then wait for 10~15 minutes until all the conditions are normalized and reactor temperature is under control. Then further proceed for load reduction to 75 %.

In the case of a Centrifugal Recycle Gas Compressor, reduce the speed of the compressor or open recycle valve in small steps so that the reactor temperature remains stable. Maintain Hydrogen to Hydrocarbon ratio in the operable range.

d. Change in Feed Composition

In the hydrotreating process, all the hydrotreating reactions are exothermic. An increase in Olefins and paraffin content in the feed will increase the reaction rate hence the reactor temperature. Check the feed composition and adjust from the upstream unit for any change. Reduce the firing rate to decrease reactor temperatures. In addition, if you feel any sudden temperature rise in the reactor, then reduce the cracked feed to minimize the effects of Olefins or any of the feed precursors. The high concentration of cracked feedstock, cocker or light gas oil (LGO), and light cycle oil (LCO), contains high sulfur, olefins, Parrafins, naphthenes, and aromatics (PNA), which results in high exothermic reactions. Regular feedstock analysis is critical to determine the presence of contaminants and to control the temperature and longer life of the hydrotreating catalyst.

e. Reduction in Feed Gas flow

As the excess feed gas not only supplies the Hydrogen for the reaction but also works as a heat carrier to remove the heat of the reaction from the reactor. Reduction, in the feed hydrogen gas flow, will result in rising in the catalyst temperature.

Maintain the compressor capacity by keeping in view the Hydrogen to Hydrocarbon ratio. Also, maintain sufficient flow of gas by controlling spill back and makeup gas flow. Moreover, verify the gas flow rate by calculations.

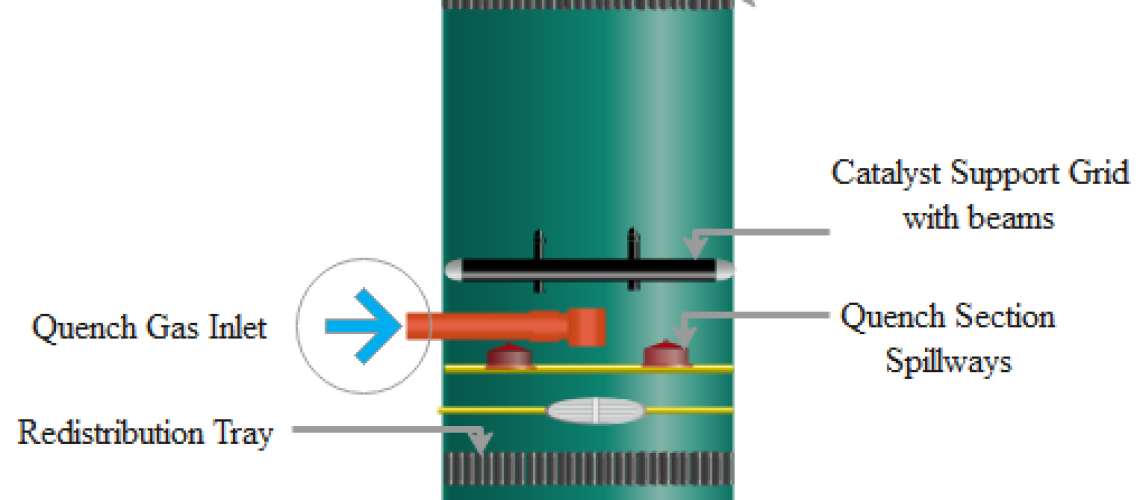

f. Reactor Quench Gas Failure

Quench gas in the hydrotreating reactor is used to provide hydrogen for reaction and to control the temperature of the downstream catalyst bed. Failure of quench gas will increase the temperature of the downstream catalyst bed. Check the working of the control valve and rectify it if any problem exists. Open bypass if available and control the quench gas flow as required. Reduce the reactor inlet temperature and maintain the second bed temperatures within the operable range. In addition, clean the quenched gas valve or line if it is clogged with debris or gummy material.

g. Methanation Reactions

CO & CO2 may get entered the Hydrocracking reactor along with makeup gas from the upstream hydrogen-producing unit. If the sudden excess concentration of CO/CO2 is allowed to enter the reactor it can cause abrupt exotherm across the reactor due to a methanation reaction which is a highly exothermic reaction.

2. The high-pressure drop across the reactor bed

The high-pressure drop across the reactor is a prominent factor to limit the cycle length of the hydrotreating reactor. Pressure drop caused by coking can be regenerated while metal contaminants have an irreversible loss of hydrotreating catalyst. The abnormally high differential pressure will damage the reactor internals and as a result, the long shutdown of the unit with the great financial loss. While if the operator sees a sudden pressure increment at the reactor inlet, then immediately unit load and gases flow should be reduced to bring the pressure drop within the operating range. If the high-pressure drop is allowed to sustain for a prolonged time, then it might damage the reactor internals.

Causes of high-pressure drop across the hydrotreating reactor

a. Damaging of Feed Filters

Metal particles or corrosion impurities with the feed may pass through the old or damaged feed filters and will deposit on the catalyst bed. Frequently check the condition of filter cartridges for any damage and replace them immediately. Manual cleaning will deteriorate the filter elements earlier as compared to the auto backwash system.

b. The high corrosion rate in the upstream section

Monitor and control the causes of high corrosion rate and analyze the production of any acidic nature component at the upstream section. Monitor, chlorides in the feed.

c. Mechanical Failure of Reactor Internals

If an internal part or reactor has been damaged, this might result in an abnormal pressure rise across the reactor. If differential pressure increase is not taken seriously, this might further worsen the situation. The hydrotreating reactor should never be operated at pressure more than the minimum pressurization temperature (MPT) otherwise internals may damage due to stress corrosion cracking.

d. End of Run Operation

At the end of the catalyst life, the hydrotreating reactor pressure drop will also be on the higher side because of gradual particle accumulation and coke formation on the catalyst. Reactor operation can be continued at low loads to maintain the pressure drop within the limit. A permanent solution is only the replacement of the catalyst with a fresh or regenerated catalyst.

e. Fouling across the catalyst bed

The fouling agents like metal contaminants, olefins, di-olefins, etc. deposit at the pore entrances or the outer surface of the catalyst and reduce the void space of the catalyst. This deposition creates a layer affecting the accessibility to the catalyst interior and active sites, thus reducing active sites and increasing pressure drop across the reactor. Please view my previous blog about “fouling in Hydrotreating reactors.”

3. Channeling over the Catalyst Bed

Catalyst Channeling is the formation of a specific flow path by process fluid through the catalyst bed resulting from the maldistribution of process feeds. Radial spread across the catalyst bed will show the extent of the problem. The major causes of flow maldistribution are inadequate or fouled reactor internals, the unit feed rate less than the turndown rate (minimum design flow rate of feed), and improper catalyst loading. Apply the dense loading method for catalyst loading. Moreover, reactor internals might be damaged resulting in unequal flow spread across the bed.

4. High Coking Rate on Hydrotreating Catalyst

Coke formation is the deposition of hydrogen-deficient carbonaceous material over the catalyst surface. The coke covers active sites of the catalyst by physical blockage of the entrance to the catalyst pores and reduces the activity of the Hydrotreating catalyst. The coke rate results in high differential pressure across the reactor. Solutions to coke formation on hydrotreating catalysts can be seen on my blog “Reducing Coke Formation on Hydrotreating Catalysts”.

For further information, discussion and queries please comment in the box below or contact admin@ or follow us on Facebook & LinkedIn.