Hydrogen Partial Pressure (HPP) is a critical parameter related to the performance of the Hydrotreating unit. The hydrotreating reactions are favored by high hydrogen partial pressure. Hydrogen Partial Pressure is the pressure of hydrogen obtained by multiplying the total system pressure by hydrogen purity. The design pressure of the hydrotreating reactor depends upon the quality of feedstock and the target product specification. For heavy feeds with more contaminants, high hydrogen partial pressure would be required. The total pressure of the system is specified by the design pressure of a hydrotreating reactor and is maintained at a high-pressure separator. The critical effect of hydrogen partial pressure is to suppress the coke formation on the hydrotreating catalyst. The operating hydrogen partial pressure must be maintained at its maximum value to achieve the design life of a catalyst.

High hydrogen partial pressure improves the performance of the hydrotreating unit as follows;

- Complete the hydrotreating reactions due to high conversion rates at the catalyst.

- Ensure availability and physical contact of hydrogen for reactions at the catalyst bed.

- Better performance of the hydrotreating reactor.

- Extended catalyst life due to slow coking rate.

- Achieve the required degree of saturation in aromatics.

- The rise in catalyst activity for Sulfur, Nitrogen, Chlorides, and metals removal.

A reduced hydrogen partial pressure will badly affect the activity of catalyst due to a hydrogen deficient environment. Further, due to low hydrogen partial pressure, all the above-mentioned objectives will be affected, and the desired unit operation would not be possible. To achieve the desired product quality, high reactor temperatures would be required which will further aggravate the problem and reduce the catalyst useful lifespan.

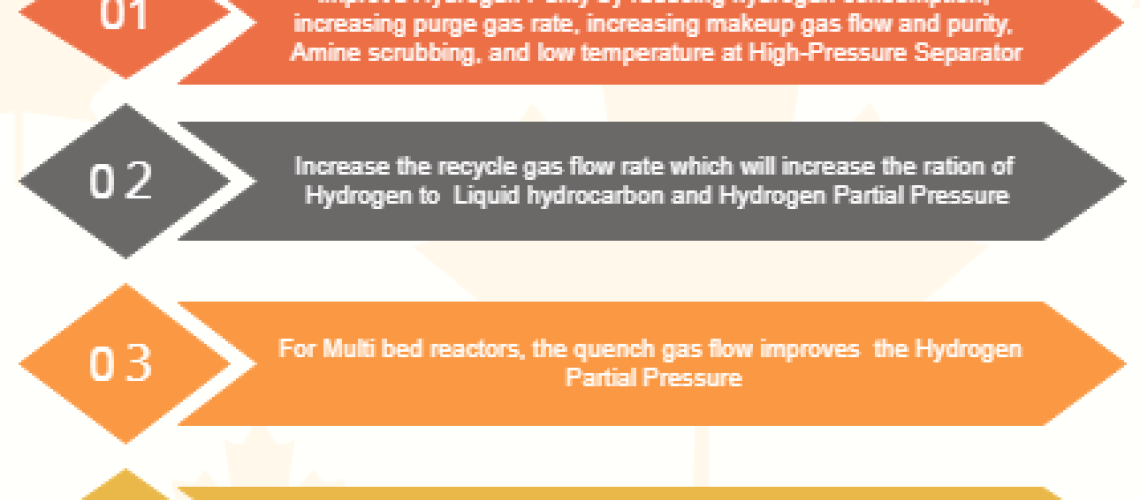

Techniques to Improve Hydrogen Partial Pressure

The Hydrogen partial pressure can be increased by improving the hydrogen purity, recycle gas flow rate, quench gas flow and the total pressure of the system.

1. Hydrogen Purity

Hydrogen purity is the major control variable of hydrogen partial pressure. Hydrogen purity must always be maintained above the minimum design value and as maximum as possible. The actions explained below will help to improve the hydrogen purity. Actions should be taken to operate the plant within design conditions.

- Reduction in Hydrogen consumption will improve hydrogen purity. Reduce the hydrogen consumption by reducing reactor temperature, replacing the heavier feeds with lighter feeds, and reducing the feed rate, while maintaining the desired product quality.

- Increase the purge gas rate from the system which will remove impurities (C1~C5) from the system, hence improving Hydrogen purity. The normal, flow of purge gas is 2~5 % of the recycled gas.

- Increase the flow and hydrogen purity of the make-up gas.

- Avoid any losses of hydrogen from the system like valves passing, leakages from the compressor, etc.

- A high concentration of H2S in the recycle gas will reduce hydrogen purity. Improve the efficiency of the Amine Scrubber to remove the H2S from the recycle gas.

- The high temperature at a high-pressure separator will cause the carryover of lighter hydrocarbons along with recycled gas that will reduce the purity of hydrogen. Maintain separator temperature at the lower side as allowed by the system or operating design conditions, so that lighter components are not moving along with recycle gas.

- Hydrogen purity can also be improved by the installation of a PSA (Pressure Swing Adsorption) Unit. In PSA makeup gas is treated to remove impurities and achieves hydrogen purity of nearly 100%.

2. Recycle Gas Flow Rate

To reduce the coke formation, it is necessary to maintain high hydrogen circulation for the desired partial pressure. An increase in recycle gas rate will increase the hydrogen to oil ratio in the reactor this will result in high HPP. The HPP and gas to oil ratio must be maintained very close to the design value; otherwise, the catalyst life will be affected. For higher gas rates, increase the compressor capacity.

3. Quench Gas Flow

For multibed reactors, quench gas not only controls the inter-bed temperatures but also improves hydrogen partial pressure.

4. Operating Pressure

Operating below its design value will reduce the partial pressure of hydrogen. Operate the system at the maximum allowable design limit of pressure. In general, higher pressure favors the reaction completion and longer life of the catalyst. Operation at higher than design may not be possible due to the pressure rating of the equipment.

For further information, discussion and queries please comment in the box below or contact at admin@ or follow us on Facebook & LinkedIn.

6 thoughts on “Improving Hydrogen Partial Pressure in Hydrotreating Units”

This one best but add some calcultions prove with formulas

A great work indeed.

Very informative great job

A good work is being done.very useful information collected and shared.Keep up the good work.