A node is a discrete part of the process or system that has a defined function with definite boundaries and is selected for analysis in the HAZOP study. Generally, they are defined as pipe sections and vessels in which process chemicals are or may be, present. The node can be a physical component, such as a vessel, a pipe, a valve, or a pump, or a logical component, such as a control loop, a process step, or a phase change.

Node selection is an important subject for two main reasons. First, it is the most accurate source for estimating the amount of time that will be required to undertake the HAZOP study. Second, the size and relative complexity of the nodes can have a significant impact on the ease of facilitation and the speed and effectiveness of the study.

Following are some general guidelines for defining the nodes, in the HAZOP study of a chemical process plant;

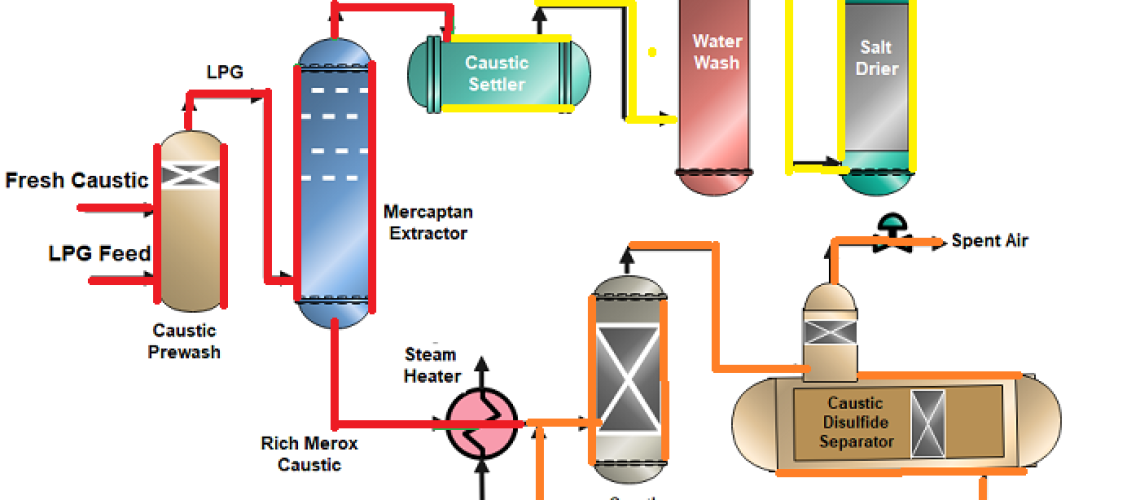

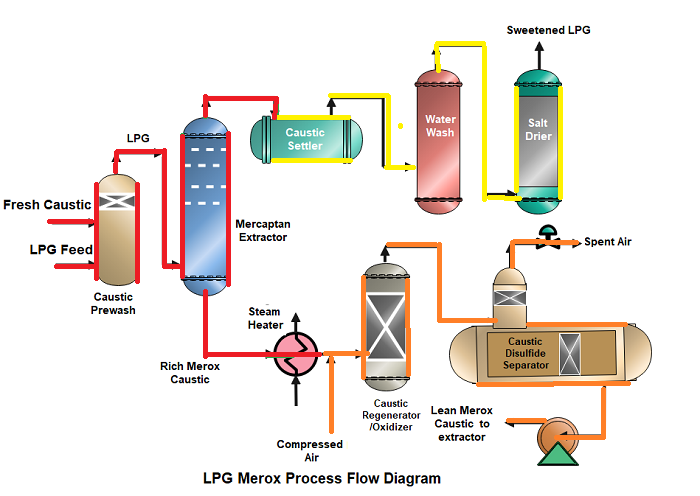

- Before identifying the nodes, the Hazop leader should be familiar with the process by using the available information sources, such as process flow diagrams, piping and instrumentation diagrams, layout drawings, operating manuals, and expert knowledge.

- Initially, the nodes should be identified on the Process process flow diagram (PFD). The PFD is a highly useful tool for defining and selecting the HAZOP nodes and boundaries. By studying the PFD, we can identify the logical and functional sections of the system, as well as the interfaces and interactions between them. The usual process for node selection is to work through the process in the direction of flow using the PFD for overall guidance.

- The node can be a physical component, such as a vessel, a pipe, a valve, or a pump, or a logical component, such as a control loop, a process step, a major piece of equipment, a phase change, or a change in design intent. To ensure that the design intention of each node can be easily and clearly understood, nodes should be selected by function (examples being such as ‘transfer’, ‘cool’, ‘heat’, ‘react’ etc.)

- Once the nodes have been defined based on the PFD, we need to determine the boundaries of each node. These boundaries can be physical, such as pipes, flanges, or fittings, or conceptual, such as design limits, operating ranges, or set points. Defining the boundaries of each node can help to isolate and focus on it individually, as well as identify its inputs and outputs.

- After defining the nodes on PFD and identifying their boundaries, the nodes are color-marked on the P&IDs. Different nodes will have different colors for their identification. It is a good idea to send the electronic copies of the marked-up nodes to the HAZOP team members before the start of the HAZOP meeting.

- At present, the method of defining nodes is to define compound nodes. For example, feed piping from a feed vessel, a centrifugal pump, a control valve set and a heat exchanger supplying a reactor vessel should be considered as a single node.

- Greater familiarity and confidence with the HAZOP methodology; the node size can be increased to include more equipment. In general, the optimum node size can include multiple items of equipment, provided, that they share a common function.

- Typically the nodes will follow the process flow, usually begins with the feed lines that enter the P&ID. Start with the feed flow into the first vessel. Make the feed flow from the upstream unit into its separate node and do not include any vessels in this node. For the next node, highlight the first major vessel, then each of its outlet lines until they hit the next vessel.

- Factors that can influence the decision on the size and complexity of a node include the experience of the leader and team, the severity of the hazards of the process, and the complexity of the control system.

- Very small nodes, such as a single process line, often lead to longer study times as each guide word combination should be recorded more times. Larger nodes, such as multiple process lines and equipment can confuse the application of guide words and if not managed properly, can lead to overlooking the hazards. As a rule of thumb try to limit the number of valves and pumps in any given node to a maximum of 5. For this rule, two pumps that are main/spare are counted as one piece of equipment.

- Some companies use combinations of lines and major vessels as nodes, “super nodes”, to speed up studies. This approach provides a broader view of a process but it complicates the analysis and scenarios may be missed.

- Often, at the end of all major and minor process flow nodes, a Global node is included. Global nodes allow initiating events that affect multiple nodes to be addressed. Initiating events may affect the entire process or parts of it, for example, some external events such as flooding, or loss of utilities such as electric power.

- Nodes should be selected by the HAZOP leader but team members can also provide their input. Generally, for a greenfield project, the team leader can mark up the nodes based on his experience but for brownfield projects, it is recommended that the nodes be marked up in consultation with the process design engineer assigned to the project.

- A major vessel is where the liquid level is controlled (e.g. fractionator tower, feed surge drum, tank, and its bottom along with its pump). Oftentimes larger vessels like towers, with multiple phases and outlet streams, are separated into different nodes. Usually, the vessel bottoms and the vessel itself are one node, while the side draw streams and overhead are separate nodes. An exception to this is if the overhead line of the vessel does not have any major equipment or systems, then it can be included with the major vessel.

- If a node has more than one operating mode, for example, normal production and in-situ molecular sieve regeneration, then each operating mode or condition should be considered as a separate node.

- Parallel trains may be reviewed independently or one train may be reviewed and the next train may be reviewed ‘by difference’ based on the If the latter approach is taken, the trains must be compared in detail to ensure that any differences in control, instrumentation, piping arrangement, and equipment design is identified and considered.

- For a batch process or procedural HAZOP, nodes represent the main process or procedural steps. To allocate a separate node to every single process step is likely to result in a large number of nodes and a significant amount of repetition. In batch processes, it is best to group the detailed procedural (or PLC-driven) steps into nodes such as 1. the addition of solvent, 2. the addition of reactant A, 3. the addition of reactant B, 4. reaction, cooling, and 5. product transfer.

Top References

- The HAZOP Leader’s Handbook by Phil Eames

- HAZOP Study by Vivek Saxena

- www.thepetrorisk.com

- https://www.primatech.com

- https://saltegra.com

- BP Hazard and Operability (HAZOP) Study (GP 48-02)

Certified Functional Safety Professional (FSP, TÜV SÜD), Certified HAZOP & PHA Leader, LOPA Practitioner, and Specialist in SIL Verification & Functional Safety Lifecycle, with 18 years of professional experience in Plant Operations and Process Safety across Petroleum Refining and Fertilizer Complexes.

- Nasir Hussainhttps://thepetrosolutions.com/author/admin/

- Nasir Hussainhttps://thepetrosolutions.com/author/admin/

- Nasir Hussainhttps://thepetrosolutions.com/author/admin/

- Nasir Hussainhttps://thepetrosolutions.com/author/admin/