Cooling towers are the backbone of heat management in industries like power plants, chemical facilities, refineries and large commercial buildings. Without them, equipment would overheat, processes would stall, and energy costs would skyrocket. By cooling water used in industrial processes or air conditioning systems, they prevent thermal pollution, save water, and keep operations efficient. This blog will break down the essentials of cooling towers, from their working principles to their key components, making it easy to understand their critical role.

What Is a Cooling Tower?

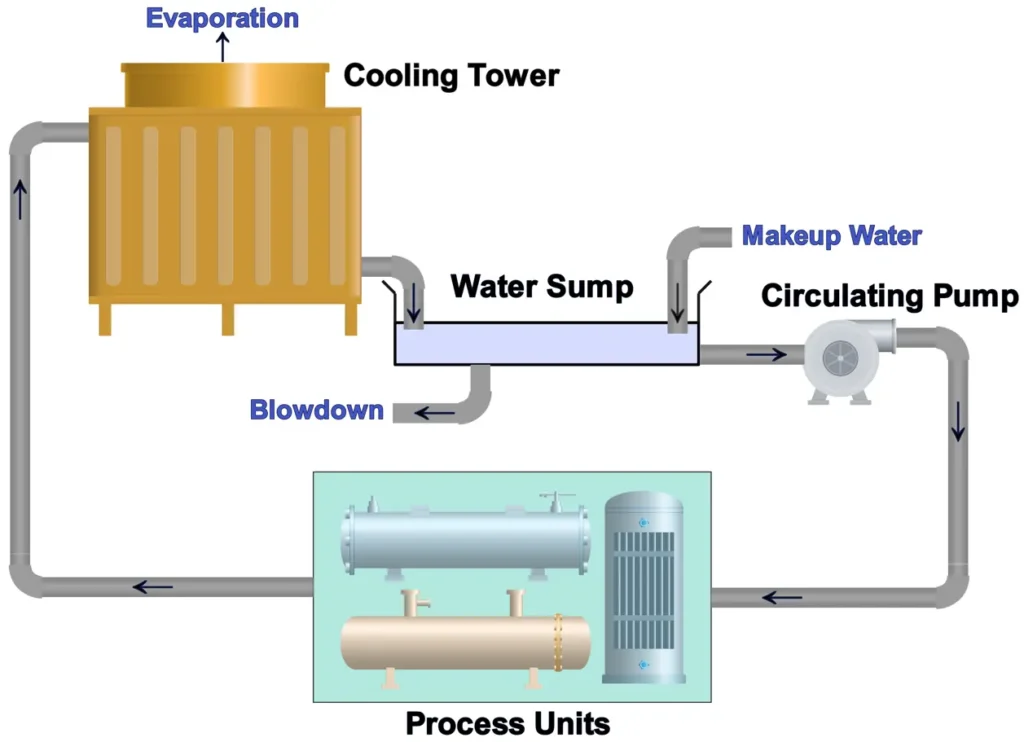

A cooling tower is a specialized heat exchanger designed to remove excess heat from water used in industrial processes or HVAC systems by transferring it to the atmosphere, primarily through evaporative cooling. Hot water from chillers or industrial equipment is circulated to the tower, where it’s cooled by contact with air. A small portion of the water evaporates, absorbing heat and lowering the temperature of the remaining water, which is then reused. This process not only prevents equipment overheating but also conserves water by recycling it, reducing environmental impact compared to wasteful once-through systems.

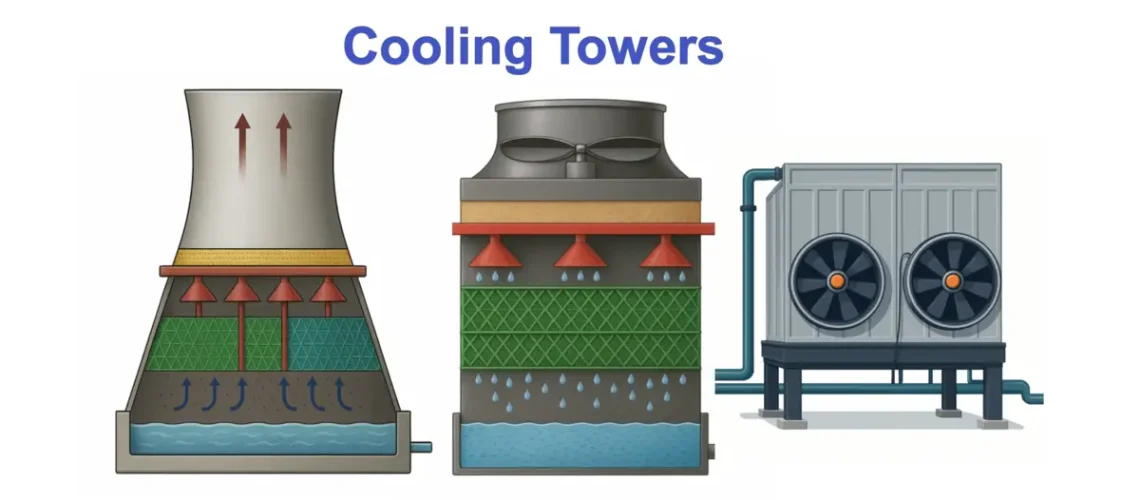

Cooling towers come in various shapes and sizes, from massive hyperbolic structures at power plants to compact units for smaller facilities. They’re essential in industries like chemical processing, power generation and refineries, ensuring machinery operates safely and efficiently.

Purpose of a Cooling Tower

Cooling towers serve several critical functions:

- Heat Removal: They dissipate excess heat from industrial processes or HVAC systems, preventing equipment damage and making the processes smooth.

- Water Conservation: By cooling and reusing water, they minimize waste, reducing water costs and environmental impact.

- Energy Efficiency: They enable systems to operate at optimal temperatures, lowering energy consumption compared to refrigeration-based cooling.

- Environmental Protection: They prevent thermal pollution by avoiding hot water discharge into rivers or lakes.

How Does a Cooling Tower Work?

The magic of a cooling tower lies in evaporative cooling, a natural process where water loses heat as it evaporates. Here’s how it works in simple steps:

- Hot Water Entry: Warm water from an industrial process or chiller enters the tower, typically at the top.

- Water Distribution: The water is spread over a heat transfer surface called fill using nozzles or basins, maximizing its surface area.

- Air Contact: Air is drawn through the tower, either naturally or by fans, and interacts with the water. A small portion (1–2%) of the water evaporates, absorbing heat.

- Heat Transfer: The evaporation process cools the remaining water, while the air picks up heat and moisture, becoming warmer and more humid.

- Cooled Water Collection: The cooled water collects in a basin at the bottom and is pumped back to the system.

- Air Exit: The warm, moist air is released into the atmosphere, often as a visible plume.

The efficiency of this process depends on the air’s wet-bulb temperature (the lowest temperature achievable through evaporation), water flow rate, and tower design. The closer the cooled water gets to the wet-bulb temperature (known as the approach), the more efficient the tower.

Types of Cooling Towers

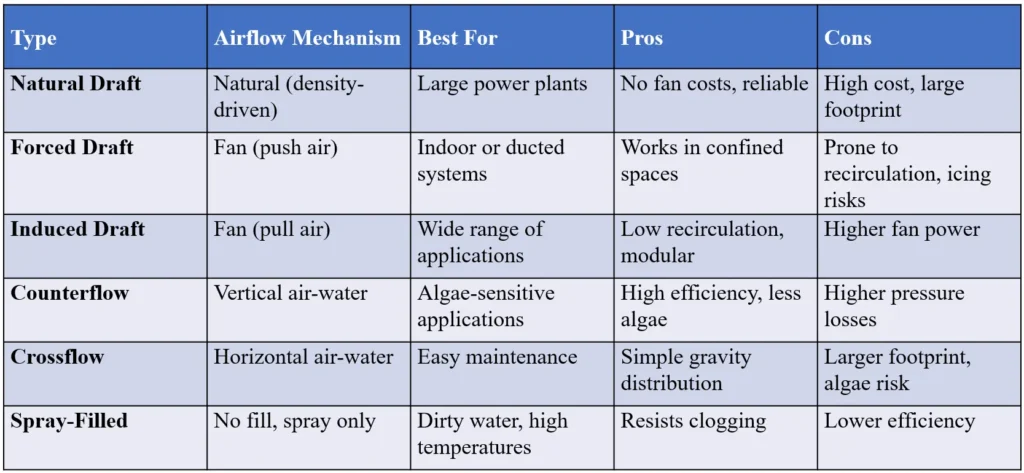

Cooling towers vary in design to suit different applications, classified by airflow mechanism, water-air flow patterns, and construction. Here’s a breakdown of the main types:

Based on Airflow Mechanism

1. Natural Draft Towers

These iconic, hyperbolic towers rely on natural air movement driven by the density difference between warm air inside and cooler air outside. They’re fan-free, making them cost-effective for large-scale applications like power plants, but their massive size and high construction costs limit their use.

2. Mechanical Draft Towers

- Forced Draft Towers: Fans at the base push air through the tower. They’re ideal for indoor or ducted setups but may suffer from recirculation of warm air, reducing efficiency.

- Induced Draft Towers: Fans at the top pull air through, offering better air distribution and lower recirculation risks. They’re widely used in industrial and HVAC systems.

3. Hybrid Draft Towers

These combine natural draft principles with fans for flexibility, boosting airflow during peak loads. They’re useful in urban areas where plume height matters.

Based on Air and Water Flow

1. Counterflow Towers

Water flows downward while air moves upward, maximizing heat transfer efficiency. They require high-pressure spray systems but limit algae growth by shielding water from sunlight.

2. Crossflow Towers

Water flows downward, and air moves horizontally across it. They use gravity-fed basins, making maintenance easier, but may need more space.

3. Spray-Filled Towers

These lack fill, relying on spray nozzles to break water into droplets. They’re used for poor-quality water to avoid clogging but are less efficient.

By Construction and Application

1. Field-Erected Towers: Built on-site for large applications, shipped in parts.

2. Factory-Assembled Towers: Pre-built for smaller setups, shipped as units.

3. Dry Towers: Use coils for sensible heat transfer without water-air contact, reducing water loss.

4. Evaporative Condensers: Cool refrigerants directly for air conditioning systems.

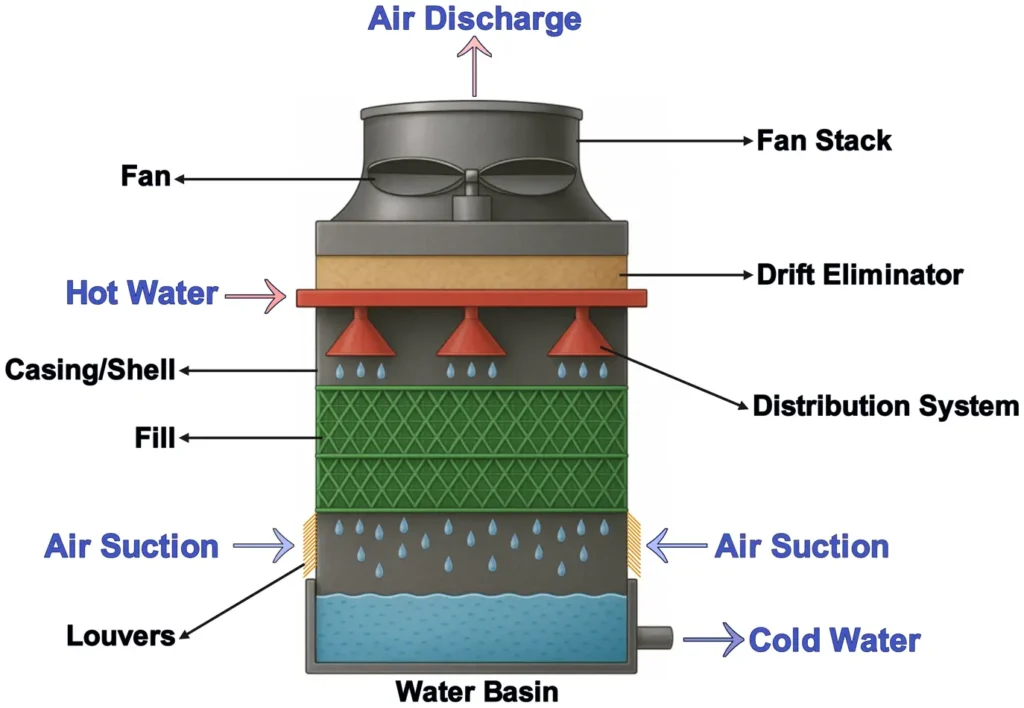

Key Parts of a Cooling Tower

Cooling towers rely on several components working together to achieve efficient heat transfer. Here’s a look at the main parts:

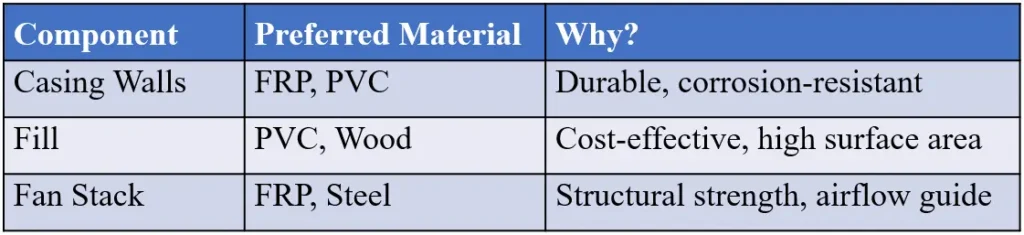

- Fill (Packing): The heart of the tower, increasing water-air contact.

- Splash Fill: Breaks water into droplets using slats (wood or PVC), ideal for dirty water.

- Film Fill: Spreads water into a thin film over PVC sheets, offering high efficiency but sensitive to debris.

- Water Distribution System: Spreads hot water evenly over the fill using nozzles (counterflow) or basins (crossflow).

- Fans: Drive airflow in mechanical draft towers, either propeller (for large volumes) or centrifugal (for high-pressure applications).

- Drift Eliminators: Capture water droplets in the exhaust air to minimize loss, using designs like herringbone or honeycomb.

- Cold Water Basin: Collects cooled water for recirculation, designed to prevent pump cavitation.

- Louvers: Guide air into the tower and prevent water splash-out, especially in crossflow designs.

- Casing/Shell: The outer structure, typically made of corrosion-resistant materials like FRP, PVC, or galvanized steel.

- Fan Stack: A tapered structure in induced draft towers that guides air exit and reduces recirculation.

- Mechanical Components: Include speed reducers, drive shafts, and valves for optimal performance.

Cooling Tower Efficiency Formula

A cooling tower’s efficiency is measured by how closely the cooled water temperature approaches the air’s wet-bulb temperature; the lowest temperature achievable through evaporation. Key metrics include:

- Range: The temperature difference between the hot water entering and the cooled water leaving (HW – CW).

- Approach: The difference between the cooled water temperature and the inlet air’s wet-bulb temperature (CW – EWB).

The efficiency formula is:

Efficiency (%) = (Range / (Range + Approach)) × 100

Makeup Water

Another key metric is the makeup water needed to replace losses from evaporation, drift, and blowdown:

Makeup Water = Evaporation + Drift + Blowdown

Where:

- Evaporation: Water lost as vapor during the cooling process in a cooling tower, typically 0.1% of water flow per °F of range.

- Drift: Water droplets carried out of the cooling tower by air, usually 0.02–0.2% of water flow.

- Blowdown: Water discharged from the cooling tower to control mineral concentration. Calculated as, where is evaporation rate and is cycles of concentration (typically 5–10).

Factors Affecting Cooling Tower Performance

Several factors influence a cooling tower’s efficiency:

- Wet-Bulb Temperature: Determines the cooling limit. Lower wet-bulb temperatures improve efficiency.

- Water and Air Flow Rates: The liquid-to-gas (L/G) ratio (0.75–1.5) affects heat transfer.

- Fill Design: Film fill offers better efficiency than splash fill but requires clean water.

- Air Distribution: Uniform airflow enhances heat transfer; recirculation reduces efficiency.

- Environmental Conditions: Wind, humidity, and nearby heat sources (e.g., other towers) impact performance.

People Also Asked Questions with Answers

Why is wet-bulb temperature important?

The wet-bulb temperature sets the lowest achievable water temperature through evaporation, directly affecting the tower’s efficiency and cooling capacity.

How can cooling tower efficiency be improved?

Use film fill for better heat transfer, optimize fan design, minimize recirculation, ensure uniform water distribution, and maintain the system to prevent fouling or bacterial growth.

Why are cooling towers important?

They prevent equipment overheating, save water, reduce energy costs, and enable processes to run efficiently in industries like power generation and chemical processing.

Why do cooling towers have a hyperbolic shape?

Hyperbolic shapes in natural draft towers provide structural stability, allow more fill at the base for better cooling, and guide airflow smoothly for a strong upward draft.

References:

- Dekker Mechanical Engineering, HVAC Water Chillers and Cooling Towers: Fundamentals, Application, and Operation (2nd Edition).

- Hill, G. B., Pring, E. J., & Osborn, P. D. (1990). Cooling Towers: Principles and Practice (3rd ed.). Butterworth-Heinemann.

- Hensley, J. C. (1985). Cooling Tower Fundamentals. Marley SPX Cooling Technologies, Inc.

- Principle of Mass Transfer & Separation Process by B.K Dutta

- https://www.sciencedirect.com

- https://testbook.com