An oil refinery or petroleum refinery is an industrial plant that transforms crude oil into useful petroleum products such as gasoline, diesel fuel, heating oil, kerosene, liquefied petroleum gas, jet fuel, asphalt base, heating oil, and fuel oils. A petroleum oil refinery also consists of a large storage facility to store intermediate and finished products.

Refineries are made up of a number of different processing units. The combination of these processing units in an oil refinery is called its configuration. The more units an oil refinery has, the better its ability to process heavier crude grades and to make a high proportion of higher-value petroleum products such as diesel and gasoline, and the more complex the refinery.

Factors Affecting Refinery Configuration

The selection of petroleum oil refinery configuration depends upon various factors but there must be an economic balance among the factors to select a refinery configuration that has the best profit margin potential with appropriate crude oil flexibility.

- The strict environmental regulations have forced the refineries to change their configuration. For example, hydro-treating is becoming an integral part to produce lower sulfur petroleum products.

- The available market and crudes. For example, in a region where crude processing, environmental, and transportation costs are high, the refineries have to convert each barrel of crude oil into a useful product.

- The refinery configuration is also influenced by the product demand. For example, in the United States, the demand for gasoline is much larger than distillate demand and, therefore, refiners configure their installations to maximize gasoline production.

- As the region develops, the dominant refinery configurations move from topping toward full conversion. North America, with a fairly mature industry, is dominated by full-conversion facilities.

Fuels based oil refineries are generally classified into four categories based on their conversion capability. As the conversion capability is increased from none to full conversion, the potential product value from a refinery increases and the crude flexibility expands. In addition, there are also non energy refineries.

- Topping Refinery with no conversion

- Hydroskimming with product treatment

- Cracking oil refinery, heavier oil conversion

- Full conversion or deep conversion, maximum conversion.

- Lube Oil Refinery

- Petrochemical Oil Refinery

1. Topping Oil Refinery

A topping refinery is the simplest refinery configuration that is designed to produce feedstock for petrochemical manufacturing plants or for the production of industrial fuels. It is a simple Crude oil distillation unit that produces large quantities of unfinished oils and is highly dependent on local markets. The crude topping unit consists of tankages, a crude distillation unit, gases, and light hydrocarbon recovery units, and the necessary utility systems (steam, power, and water-treatment plants). Some of the salient features of topping type refinery are as follows;

- Typically, only condensates or light sweet crudes would be processed at this type of facility unless markets for heavy fuel oil are readily and economically available. Asphalt or Bitumen plants are also configured with topping refineries that accept heavy crude oil from which the asphalt is produced.

- The crude topping unit may produce up to half of their output as residual fuel oil and can face increasing market loss as the demand for low sulfur (even no sulfur) and high sulfur fuel oil increases.

- The products are poorly-refined because they lack the required downstream processing units to produce low-sulfur high-quality fuels.

- As a result of the limited process capabilities of topping oil refineries, these facilities are usually found in locations where environmental regulations are flexible and where there is a use for the intermediates, or at oil field processing facilities to stabilize the crude oil.

The advantages of the crude topping unit lie in its simplicity and low cost. It is relatively easy to operate a crude column as compared to more complex refineries.

The key disadvantages of topping refineries are the limited crude slate, products that will not meet most environmental specifications and must be sold as intermediates, and the production of a lot of low-value products (like fuel oil). This type of refinery is usually not economically viable in low-margin periods.

2. Hydroskimming Oil Refinery

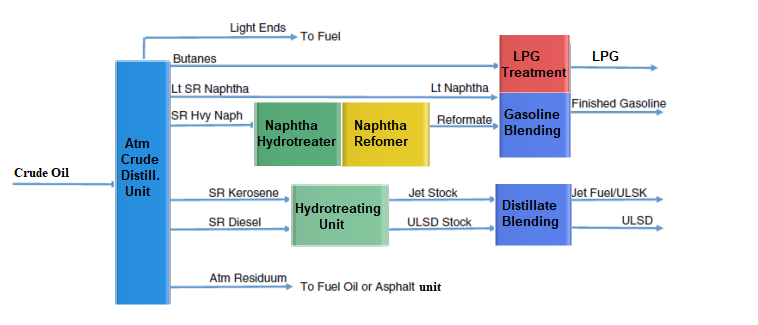

The next level of refining is the hydroskimming refinery, which is more complex than the topping refinery. The Hydroskimming refinery consists of an atmospheric distillation unit, naphtha reforming, and necessary treating units. This hydroskimming gets its name due to the addition of the reforming unit because it produces hydrogen from hydrocarbon and high-octane gasoline. Hydrogen produced by naphtha reforming is the key process to upgrading the quality of refinery products through hydrotreating.

The addition of hydrotreating and reforming units to the basic refinery configuration results in a more flexible petroleum refinery that can produce desulfurized distillate fuels and high-octane gasoline.

The key disadvantage of hydroskimming oil refinery is the production of a significant amount of residual oil and the refinery is limited to lighter crude feeds. A significant reduction in demand for furnace oil has put Hydroskimming refineries in danger. Products from a hydroskimming refinery could include light ends (C1–C4), finished gasoline, finished jet fuel, and ultralow sulfur diesel. The light ends may also be upgraded to improve their value (e.g., isomerizing butanes).

3. Conversion or Cracking Oil Refinery

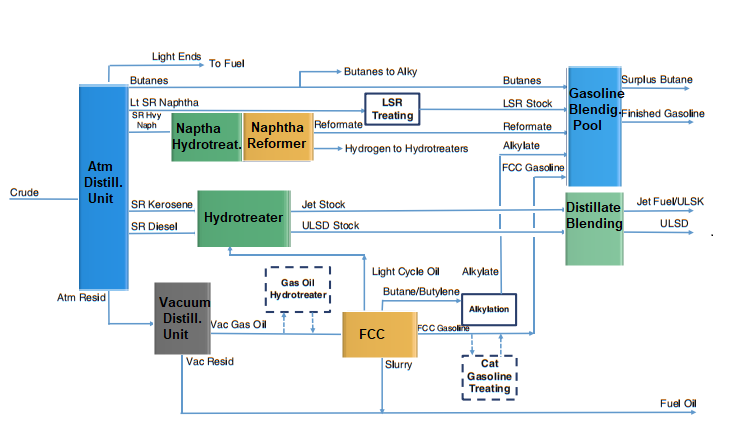

A conversion refinery incorporates all the basic units that exist in both the topping and hydroskimming refineries. In addition, the conversion refinery has residual oil conversion plants such as catalytic cracking and hydrocracking units, and the olefin conversion plants such as alkylation or polymerization units.

The cracking oil refinery configuration processes reduced crude, vacuum residue or residual oil into more valuable gasoline and distillate components using catalysts, high temperature, and high pressure. Compared to hydroskimming, a cracking refinery adds a vacuum distillation unit and a fluid catalytic cracking (FCC) unit plus an alkylation unit or a hydrocracker to convert the vacuum gas oil. Additional feed or product treatment is needed to meet the most stringent specifications.

A cracking refinery with a high gasoline market will favor an FCC (Fluid Catalytic Cracking) route. Residues can also be converted in Residue Fluid Catalytic Cracking (RFCC). In a diesel market, the cracking refinery would favor hydrocracking over FCC.

The advantages of a cracking refinery are the great increased crude oil flexibility and the production of more high-value products per barrel of crude. This type of facility can produce more variation in margins than either topping or hydroskimming. But to obtain operational flexibility the conversion or cracking refinery needs higher capital and operating costs.

4. Deep Conversion, Coking or Full conversion, or Complex Oil Refineries

A deep conversion refinery is the last level of refining and a combination of all components of a conversion refinery and an additional unit known as the coking unit. The cooking unit makes it possible to treat and convert extremely heavy crude oil fractions into lighter products. Further, a deep conversion refinery also converts the gases or any other hydrocarbon feedstock into petrochemicals.

The installation of additional conversion capability increases the yield of clean products and reduces the yield of heavy fuel oil. However, increased conversion capability would generally result in higher energy use and, therefore, higher operating costs. These higher operating and capital costs must be weighed against the lower cost of the heavier crude oil and profits earned from the sale of products.

- The deep conversion refinery configuration gives the flexibility to refiners to process cheaper, heavier crude and lower quality synthetic crude and have the flexibility in their crude buying decisions.

- Modern catalytic cracking and coking refineries produce high outputs of gasoline, with the balance distributed between liquefied petroleum gas, jet fuel, diesel fuel, and a small quantity of coke. Many such refineries also incorporate solvent extraction processes for manufacturing lubricants and petrochemicals to recover propylene, benzene, toluene, and xylenes for further processing into polymers.

- You can see that the potential margin increases significantly with increasing conversion. These margins do not include operating costs or transportation, which reduce the actually realized margin for each type; but the trend toward more profitability for a more complex facility still remains, even after factoring in the costs.

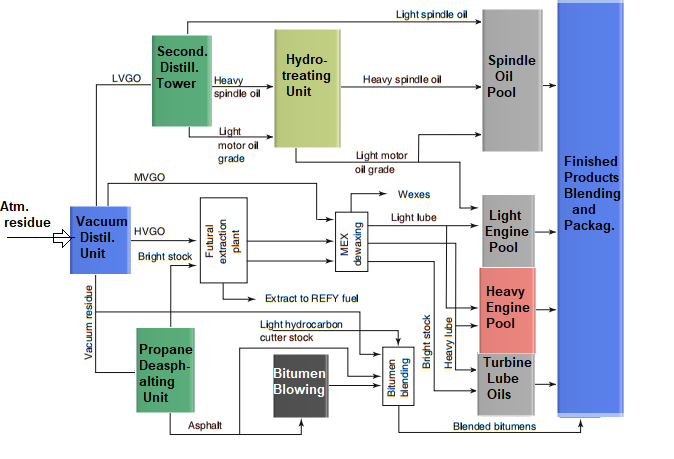

5. Lube Oil Refinery

In Lube Oil Refinery, the processes used involve extraction and dewaxing of conventional petroleum stocks. Only about 8~10 base lube oil stocks are produced from the refinery streams. The many hundreds of commercial grades of lubricating oils used in industry and transportation are blends of these base stocks with some small amounts of proprietary additives (mostly organic acid derivatives) included to meet their required specifications.

There are also two quite important by-products of lube oil. These are bitumen and waxes. Most refineries include bitumen blending in their configuration, but only a few of the older refineries process the waxes.

6. Petrochemical Oil Refinery

Feedstocks for the production of petrochemicals originate from refineries with processes similar to those described earlier to produce fuels. Indeed, there are only a few refineries worldwide that cater only to petrochemical requirements. Most petrochemical feedstocks are produced by changing operating parameters of the normal fuel refinery processes. In catering for the petrochemical needs, much of the refinery product streams are tailored as follows:

- Aromatic streams – high in benzene, toluene, and xylenes and produced naphtha catalytic reforming or a naphtha stream from Hydrocracking unit.

- Olefin streams – high in ethylene, propylene, and C4s and are originated from the FCCU, a thermal cracker or a steam cracking unit.

Top References:

- An introduction to Petroleum Technology, Economics, and Politics by James G.Speight

- Tank Farm Nigeria

- Handbook of Petroleum Processing by Steven A. Treese • Peter R. Pujado, David S. J. Jones

- Petroleum economics and engineering edited by Hussein K. Abdel-Aal and Mohammed A. Alsahlawi

- Handbook of petroleum refining by JAMES G. SPEIGHT

- Springer Handbook of Petroleum Technology by Chang Samuel Hsu and Paul R. Robinson (Eds.)

For further information, discussion and queries please comment in the box below or contact us at admin@ or follow us on Facebook & LinkedIn.