The Sulfur Recovery Unit (SRU) in a Petroleum Refinery is designed to remove H2S from sour gases originating in the various refinery processes and convert them to industrial-grade molten sulfur. The process used in the sulfur recovery units in the petroleum oil refineries is known as the “Claus Process”, which removes 95-99.9 % of hydrogen sulfide present in the gas streams. The modified Claus Sulfur recovery process burns the H2S-rich sour gas with oxygen, cools the burnt gas, and recovers molten sulfur from the burnt gas.

Tail gas in the refinery is the gas left after maximum recovery of the H2S from the refinery sour gases stream in the Sulfur Recovery unit that contains H2S, H2, SO2, Nitrogen, CO2, and minor elemental sulfur components. The tail gas still contains at least 5% of sulfur-containing compounds. A Tail Gas Treatment Unit (TGTU) aims to maximize the conversion of sulfur compounds to H2S. The refinery’s sulfur recovery plant can recover sulfur of the highest purity. The sulfur recovery rate is typically between 94.5~97.5%, although with an efficiently run Tail Gas Treatment Unit, sulfur recovery efficiency can be increased up to 99.99%.

Tail Gas Treatment Section also called as Shell Claus Off-gas Treating (SCOT) process removes the sulfur compounds such as hydrogen sulfide (H2S), sulfur dioxide (SO2), and elemental sulfur (S8), etc. in the tail gas from the Sulfur Recovery Section. In the TGT section reduction/hydrogenation of the sulfur compounds (SO2 and elemental sulfur (S6, S8) to hydrogen sulfide takes place which is removed by an amine solution. The rich amine after hydrogen sulfide absorption is regenerated to release the absorbed hydrogen sulfide. The desorbed H2S is recycled back to the SR section for further recovery of elemental sulfur. An overall recovery efficiency in excess of 99.9 % can be attained by both SR and TGT sections.

Tail Gas Treating Unit Process Description

Shell’s amine-based SCOT (Shell Claus Off-gas Treating) tail gas cleanup process is the best solution for these operational processes. The SCOT process is the most cost-effective method for attaining 99.7% or greater total sulfur recoveries. The Shell Claus Off Gas Treatment (SCOT) technique, developed by Royal Dutch Shell labs in the Netherlands and licensed in the United States by Shell Development, was presented to the industry in late 1972.

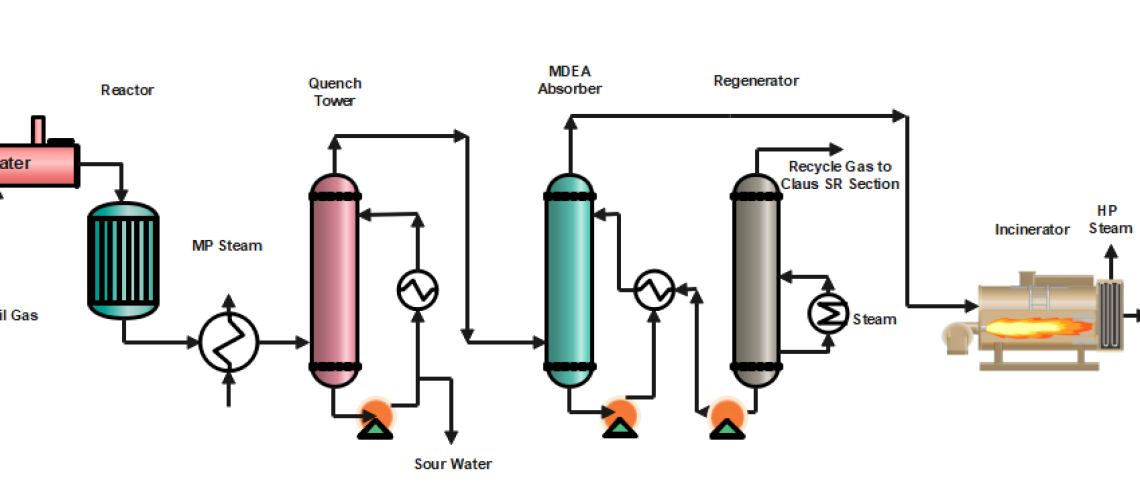

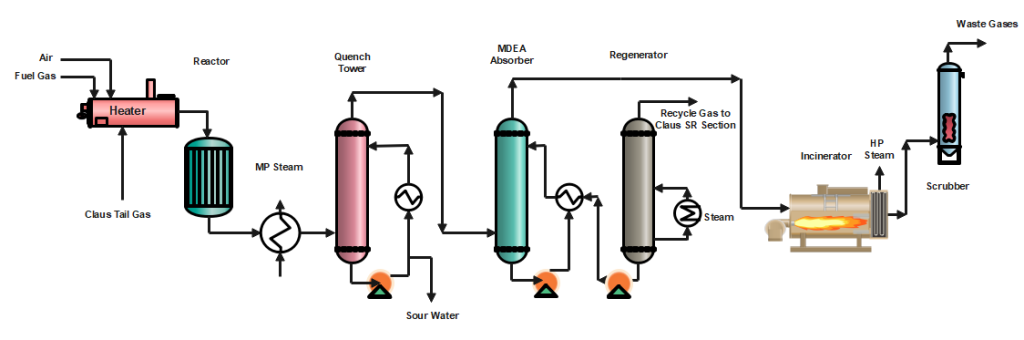

The Process Flow Diagram of Tail Gas Treatment is shown below;

The SCOT process is divided into three stages:

- Heating of the Tail Gases

- Hydrogenation of Tail Gases

- Absorption and Regeneration

- Incineration of Waster Gases

1. Heating of Tail Gases

Claus tail gas that contains some hydrogen sulfide, sulfur dioxide, and S6/S8 is heated upto ~300°C in a gas-fired heater called SCOT Heater or using the waste heat of the incinerator flue gas for heating and setting up an online heating boiler to generate high-temperature flue gas for direct mixing and heating. After that gases are passed to the Scot Reactor.

2. Hydrogenation of Tail Gases

Sulfur dioxide and other sulfides are hydrogenated to create hydrogen sulfide under the control of a particular catalyst. The hydrogen required for reactions is provided from the Hydrogen production unit like the Naphtha Reforming unit of a petroleum refinery. In the SCOT reactor, a bed of cobalt-nickel or cobalt-molybdenum catalyst enables the hydrogenation of the rest of the sulfides present in the heated tail gas supply to produce H2S under the following reactions:

SO2 + 3H2 → H2S + 2H2O

1/x Sx + H2 → H2S

In the hydrogenation reactor, the carbon hydride sulfide and carbon disulfide hydrolysis process also occur. The equations are as follows:

COS + H2O → H2S + CO2

CS2 + 2H2O → 2H2S + CO2

The hydrogenated tail gas is cooled in the waste heat boiler, producing medium-pressure steam, and is then further cooled in a quench tower down to 50~90 °C.

3. Absorption and Regeneration

The cool gas enters the absorber, where it is contacted with a 25-50 wt% Methyl Di Ethanol Amine (MDEA) aqueous solution to absorb H2S selectively and leave CO2 ~90 % in the off-gases. The absorbed H2S and CO2 gases are extracted by increasing steam as the rich MDEA solution flows down the stripper. After cooling to 30~48 °C, the retrieved solvent from the stripper’s bottom is recycled back into the absorber. At the top of the stripper, CO2, and H2S are recycled to the Claus sulfur recovery unit, where sulfur is recovered.

4. Incineration Section

The clean absorber gas can have less than 10 ppm of total sulfur compounds remaining after the Tail Gas Treatment Section. It is then sent to a final thermal Incinerator to convert gases such as H2S, COS, CS2, and elemental sulfur to SO2 by complete oxidation with excess air for a safer emission at the final stack. Increasing temperature up to ~ 760°C can achieve residual H2S content of not more than 10 ppm. A high-Pressure steam superheater is provided to recover the waste heat of the flue gas.

Top References

- Springer ~ Handbook of Petroleum Technology Hsu Robinson Editors.

- Handbook of Petroleum Processing, 2nd Edition by Steven A. Treese, Peter R. Pujado, David S. J. Jones.

- https://www.sciencedirect.com/- SCOT Process

- Handbook of Petroleum Refining, James G. Speight