Hydrogen is one of the most important elements in petroleum refineries, and is in various refining processes to upgrade the petroleum products quality. Demand for hydrogen in petroleum refineries has increased significantly due to the stricter environmental regulations, processing of heavier crude oils, and conversion of residues into lighter more valuable products. However, the increasing demands for hydrogen require advanced hydrogen management and on-purpose production of more hydrogen through various processes.

Efficient management of the hydrogen network is essential for optimizing refinery operations, minimizing energy consumption, and meeting product quality specifications and environmental standards. Refineries continuously strive to enhance hydrogen production, distribution, and utilization processes to maximize their overall efficiency and sustainability.

The estimated production cost of Hydrogen is 125~150 USD/Ton of hydrogen. Only saving, 1 ton per hour can save up to 8.7 K-Ton Hydrogen per year and 1.3 million USD per year. It is recommended to utilize in processing more than 90 % of the hydrogen produced.

Uses of Hydrogen in Petroleum Refinery

- Eliminate sulfur, nitrogen, and other impurities from petroleum products like naphtha, kerosene, diesel products or other feedstocks in Hydrotreating units.

- Upgrade product values (ULSD, dewaxing, isomerization).

- Crack heavier hydrocarbons (gas oils) into lighter hydrocarbon products (naphtha, distillates).

- Extra hydrogen along with C1~C4 can be used in refinery fuel gas systems.

Hydrogen Network in Refinery

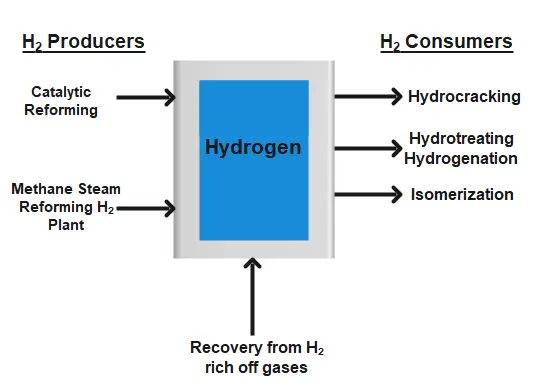

A hydrogen network in a petroleum refinery refers to a system that produces, distributes, and utilizes hydrogen within the refinery complex. High-pressure pure hydrogen is sent to one of the consumers and the purge gas of that consumer is treated and diverted to the downstream unit using the same pressure. The network covers from generation to consumption and then finally purging to the refinery fuel gas system. Here’s an overview of the hydrogen network in a petroleum refinery;

1. Hydrogen Production

Refineries typically produce hydrogen through various processes, including Naphtha Catalytic Reforming, Steam Methane Reforming (SMR), partial oxidation of natural gas or other Hydrocarbon feedstocks and recovered hydrogen from refinery off-gases stream. Naphtha Catalytic Reforming is the most common method. Additional hydrogen demand is met by other on-purpose hydrogen production units or through external import.

The hydrogen production unit produces hydrogen with normally high purity (~ 90 %) which can be further improved up to 99 % by applying hydrogen purification methods. For further study please also view my blog “Hydrogen Production in Petroleum Refineries”.

2. Hydrogen Distribution

Once produced and purified, the hydrogen is distributed throughout the refinery complex via a network of pipelines or dedicated distribution systems. The distribution network delivers hydrogen to various process units that require it according to the pressure and purity requirements.

3. Hydrogen Utilization

Hydrogen is used in several refining processes, primarily for the purpose of removing impurities and upgrading the quality of petroleum products. Some of the key applications of hydrogen are Diesel, Naphtha or Kerosene Hydrotreating units, Residue or Gas Oil Hydrocracking, Naphtha Isomerization units, Hydrodealkylation etc. For hydrotreating of lighter petroleum streams if high purity Hydrogen is used ~>90%, then gases normally are not bleeded and are used only for maintaining the pressure of the system.

4. Hydrogen Recovery and Treatment

- Amine units (scrubbers) remove H2S from recycle gas of the hydrotreating units, refinery off gases and transport the H2S to a sulfur recovery plant. Scrubbed gases often contain recoverable hydrogen. Hydrogen may also be purged to manage the purity of recycle gas, or sometimes for system pressure control.

- Lean oil recovery (LOR) recovers C3–C6 hydrocarbons, mostly C3–C4, from off-gas streams and improves the purity of the off-gas stream. The hydrocarbon-rich oil goes to a stripper, where the hydrocarbons are covered. LOR is one of the most cost-effective hydrogen purification units.

- Pressure-swing adsorption (PSA) The pressure-swing adsorption removes nearly all contaminates, yielding a product containing 99:99% hydrogen.

- Membrane units employ semipermeable membranes to purify hydrogen, providing hydrogen with a purity of ~ 95%.

- Cold Box or Cryogenic units can be designed to separate H2 and CH4 from other gases, to separate H2 and N2 from CO, etc., at cryogenic temperatures.

The treated and recovered hydrogen gas is normally added to the refinery hydrogen network and can be used as per process requirements. For example, the purge gas of the Hydrocracking unit can be treated through PSA or Membrane Technology process and then can be utilized in other hydrotreating or Isomerization Units.

Common Hydrogen Losses in Refinery

Hydroprocessing units consume hydrogen chemically in their reactions. Isomerization units consume less hydrogen – just enough to keep the catalysts clean. Following are some common hydrogen losses locations in petroleum refineries;

- Entrainment and solution losses from separators to strippers along with Hydrocarbons in Hydroprocessing units. Stripper hydrogen usually ends up in the fuel gas system but can be treated to recover the hydrogen.

- Purging to fuel gas accounts for most of the hydrogen lost in refineries.

- Mechanical losses from the compressors seals.

Guidelines for Hydrogen Optimization in Petroleum Refinery

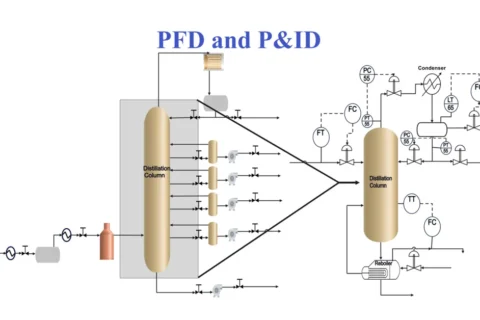

- Treat and give value to the hydrogen system like any other process system and have a process flow diagram at DCS with critical controls shown and a material balance for the hydrogen system.

- Measure and monitor flows and composition of all the hydrogen streams to and from the processing units.

- Produce or buy the lowest possible amount of “on-purpose” hydrogen. Use the hydrogen in the units as per the requirement of the process to meet the product quality, and avoid its over-use.

- Preferably use hydrogen in the highest value units and avoid waste in the refinery fuel gas system or flare header purging. A significant amount of Hydrogen can be recovered from fuel gas and flare-purged gas stream and can be utilized in processing units.

- Minimize the need to recompress hydrogen by cascading from high to low-pressure units where possible.

- Recover hydrogen where feasible, like units purge gas, a refinery or stripper off-gas and flare header purge gas streams using suitable technology.

- In refinery planning, the refinery LP model should consider hydrogen. With good practices, a refinery should be able to use more than 90 % of the hydrogen generated.

- A periodic review of the Hydrogen Syteam by a reputable company experienced in hydrogen system optimization is advisable.

- A rise in the temperature of catalytic units will increase hydrogen consumption. Temperature conditions should be maintained as per product quality requirements.

- Changes in crude oil quality impact the use of Hydrogen. A heavy, sour crude will require more hydrogen to refine than a light, sweet crude oil. Hydrocracker and Hydrotreating units will require deeper Hydrodesulfurization or increasing conversion will increase consumption.

- It is advisable to have a simple model that predicts hydrogen consumption or production for each unit based on feed rate and quality to estimate changes.

- Ensure that process conditions such as temperature, pressure, and catalyst activity are optimized for maximum hydrogen efficiency. Fine-tuning these parameters can help to reduce hydrogen consumption.

- During the startup and pressurization of hydroprocessing units, most of the Hydrogen is flared. It is advisable to produce the Hydrogen only as per requirement and divert the excess hydrogen to other units for pressurization or at least to the fuel gas system.

- Regularly inspect and maintain the refinery infrastructure to minimize hydrogen leaks. Leaks can result in significant hydrogen losses over time. Utilize advanced leak detection techniques and repair any leaks promptly.

- Hydrotreating and hydrocracking processes consume significant amounts of hydrogen. Implement advanced catalysts and technologies that enhance hydrogen utilization, such as high-activity catalysts and optimal reactor design.

- Ensure efficient purification of hydrogen streams to remove impurities. Effective purification can help maintain catalyst performance, reduce corrosion, and improve overall efficiency.

- Utilize advanced monitoring and control systems to optimize hydrogen distribution and utilization throughout the refinery. Real-time data analysis and process optimization can help identify areas where hydrogen consumption can be minimized.

- Provide comprehensive training to refinery operators and staff on hydrogen management, including best practices for monitoring, and minimizing hydrogen consumption.

References:

- Springer Handbook of Petroleum Technology

- Handbook of Petroleum Processing by Steven A. Treese Peter R. Pujadó David S. J. Jones

- Handbook of Petroleum Refining by James G. Speight

1 thought on “Hydrogen Management in Petroleum Refinery”

Hi, are you please aware of refineries use H2 buffer to avoid flaring of H2 please ?