The flaring process in oil refineries refers to the controlled and safe burning of the waste gases that are produced during various refining processes. By burning the hydrocarbon vapours the pollutants are converted into safe and less toxic components. However, the combustion process of a flare generates lots of thermal radiation and greenhouse gases from the flame. In the oil and gas upstream, gas flaring is the burning of natural gas associated with oil extraction.

Why Flaring is Necessary?

Flaring converts the hydrocarbon wastes produced during various refining activities into safe and less toxic gaseous. Before the utilization of flares in the petroleum industry, the waste gaseous streams were vented directly into the atmosphere. The following are the effects of the direct venting of waste gases into the atmosphere;

- This created problems for the operating personnel and the nearby community because there was always the possibility of combustible vapour reaching the ground in sufficient concentration to be ignited. This could result in an explosion and fire, with devastating consequences for the operating personnel.

- Further, direct discharges of hydrocarbon produce a damaging impact on the environment and toxicity on the local community and operating personnel.

Sources of Flare Gases in Petroleum Refinery

Some of the major sources of gases to flare are as follows;

- In petroleum refineries, flare stacks are primarily used for burning off flammable gases released by safety valves during unplanned over-pressuring of plant equipment.

- During plant startups and shutdowns, flare systems are used for the planned flaring of gases over relatively short periods to maintain the plant operation smoothly.

- Further, during process upsets (Utility failures, thermal runaways, equipment failure, etc.) hydroprocessing catalytic reactors are depressurized to flare to save the catalyst.

- Moreover, flaring is necessary for the safe handover of the process equipment during maintenance. Process equipment is depressurized, and steam out towards the flare to remove the liquid and gaseous hydrocarbons, toxic gases (H2S) etc.

Flare System in Petroleum Refinery

The flare system is designed to provide safe receipt and disposal of combustible, toxic gases and vapours released from process equipment during normal operation and during upset conditions. The stack is located remote enough from operating units to provide safety for operating personnel and equipment.

Normally, a flare system in a Petroleum refinery consists of two types. One is the main flare system that manages the gases from the non-toxic sources and the other one is the acid flare system that collects and burns the toxic gases.

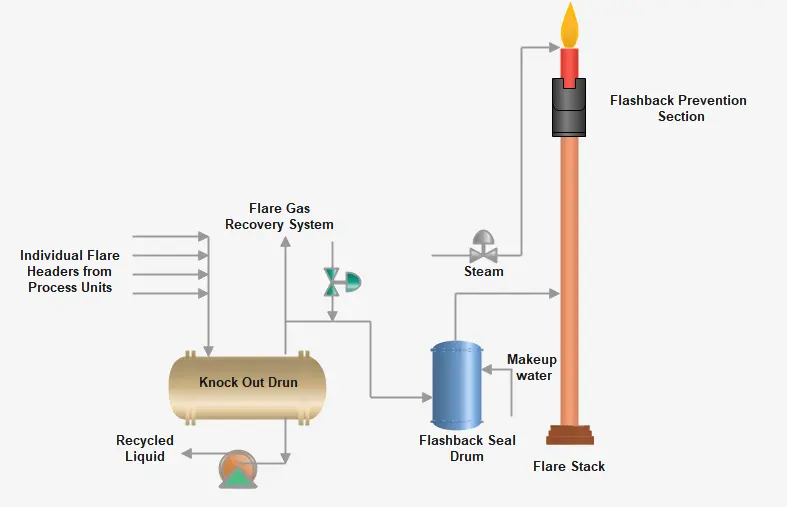

In petroleum refineries, the released gases and liquids are routed through large piping systems called Flare Headers to a vertical elevated flare. From all process units, the small headers are connected to the main flare header. The released gases are burned as they exit the flare stacks. To keep the flare system functional, a small amount of gas is continuously burned, like a pilot light, so that the system is always ready for its primary purpose as an over-pressure safety system. In addition, the fuel gas is also injected into the flare header from individual process units to keep the header alive and slightly pressurized to avoid air ingress into the system.

- A typical flare system of a petroleum refinery consists of a knockout drum close to the flare that removes any oil or water from the relieved gases. The liquids are recycled and reprocessed into petroleum products.

- A water seal drum and emergency purge gas system to prevent any flashback of the flame from the top of the flare stack.

- An alternative flare gas recovery system for use during normal operations, plant startups and shutdowns as well as other times when required. The recovered gas is routed into the fuel gas system of the overall industrial plant.

- A steam injection system provides an external momentum force used for the efficient mixing of air with the relieved gas, which promotes smokeless burning.

- A pilot flame (with its ignition system) burns all the time so that it is available to ignite relieved gases when needed.

- The flare stack, including a flashback prevention section at the upper part of the stack.

Types of Flaring

There are three types of gas flaring in the petroleum industry; (i) Routine Faring which is carried out to keep the flare and flare header alive; (ii) Safety Flaring is the result of discharges from pressure safety valves; and (iii) Non-routine Flaring arises due to plant emergency situations and handover of process equipment for maintenance.

Categorizing each type of gas flaring in this way allows the identification of potential actions for its mitigation in new or existing facilities. This mitigation may be through (i) Commercial solutions, on-site utilization or re-injection for routine flaring; or (ii) Improved facility design and or operational procedures for routine, non-routine, and safety flaring.

Effects of Gas Flaring

1. Environmental impact

In flaring, the combustion of HC releases carbon dioxide, CO2, CO, NOx, SOx and other greenhouse gases into the atmosphere, contributing to climate change. Flaring also releases other harmful pollutants such as particulate matter, volatile organic compounds (VOCs) (benzene, toluene and xylene) and small quantities of sulphur compounds such as carbon disulphide (CS2) and carbonyl sulphide (COS).

Although flaring is considered to be a safe alternative for disposing of refinery waste gases the gases produced during flaring also have damaging impacts on the local community. A purge gas recovery system should always be implemented to control the flaring to a minimum i.e. only to pilot burning.

Recovering flare gas not only has environmental benefits but also it has economic incentives. Owing to the environmental regulations to reduce greenhouse gas emissions, petroleum and natural gas production facilities worldwide have intensified their efforts to achieve the Zero Flaring targets.

2. Waste of Resources

Flaring natural gas or hydrocarbon gases from refinery wastes a valuable resource. The gas could be captured and used for fuel or sold as a commodity. Flaring also contributes to the depletion of natural gas reserves.

3. Regulatory Issues

Flaring is subject to regulatory oversight and can result in fines or other penalties if not properly managed. In some cases, flaring may be prohibited or restricted by local or national regulations.

Top References

- Refining Processes Handbook by Surinder Parkash

- Petroleum Development Oman

- www.aiche.org

- www.worldbank.org

For further information, discussion and queries please comment in the box below or contact us at admin@ or follow us on Facebook & LinkedIn.