Estimating the duration of a HAZOP study is one of the most challenging responsibilities of a HAZOP leader. There are no universally accepted rules for determining how long a HAZOP will take, because study duration is influenced by a wide range of technical, organisational, and human factors. Over time, practitioners have developed several rules of thumb and more complex estimation models, each with strengths and limitations.

This blog consolidates practical guidance from industry experience and published methods to help HAZOP leaders make realistic, defensible time estimates—and avoid the common pitfall of underestimating effort.

HAZOP duration is influenced by many inter-related variables, and no existing method captures them all. Simple estimation methods focus on a single driver—such as P&IDs, nodes, or equipment—while ignoring softer but equally critical factors like team dynamics, documentation quality, and leader experience.

As a result, all time estimates should be treated as planning tools, not precise predictions. The experience and judgement of the HAZOP leader remain the most important inputs.

Key Factors Affecting HAZOP Length and Pace

Before applying any estimation method, it is essential to understand the factors that directly affect both study duration and rate of progress.

1. Process and Methodology Factors

- Scale and scope of the process

- Batch versus continuous operation

- Nature and severity of process hazards

- Number of operating modes (normal, start-up, shutdown, emergency)

- Process and system complexity

- Novelty of technology

- Number of deviations to be examined

- Node size and complexity

- Style and level of detail of recording

2. Information Quality

- Quality, clarity, and completeness of P&IDs

- Extent of available process safety information (PSI)

- Accessibility and organisation of documentation

3. Team Factors

- Experience and competence of team members

- Size of the team and continuity of attendance

- Experience and effectiveness of the HAZOP leader and recorder

4. Work Pattern

- Length of daily sessions

- Frequency of breaks

- Consistency of study schedule

No rule of thumb compensates for weak documentation, inexperienced teams, or poor facilitation.

5. Learning Curve and Start-Up Effect

Most estimation methods are derived from longer studies (typically over one week). This is because HAZOP teams rarely achieve steady productivity on Day 1.

Early sessions are slower due to:

- Introductions and alignment

- Explanation of methodology

- Development of ground rules

- Team learning and calibration

A realistic and conservative assumption is that no full node will be completed on the first day. Building this pessimism into the schedule gives the leader time to properly set expectations—an investment that almost always pays back in later productivity.

Time Estimation Methods/Rules of Thumb

1. P&ID-Based Estimation (Crude, Early-Stage Method)

Used when node selection is not possible before agreeing the Terms of Reference:

- 1–2 P&IDs per day

- Based on ~6 hours of meetings per day

- Assumes good-quality, up-to-date, non-complex P&IDs

- Excludes preparation and reporting time

This method is suitable only for initial, high-level planning.

2. Node-Based Estimation (Preferred Method)

A more reliable and defensible approach:

Continuous Process HAZOP: 2–3 nodes per day

Batch / Procedural HAZOP: 1–2 steps per day

Key points:

- Based on ~6 hours of meetings per day

- Excludes preparation and reporting time

- Additional time must be added for start-up, shutdown, and other operating modes

Some US sources suggest higher rates (up to 3–6 nodes/day), but sustaining such speeds risks superficial analysis. Occasional high-productivity days may occur, but they should not be used as planning baselines.

Node-based estimation aligns best with how HAZOP is actually performed, since the node—not the P&ID—is the true unit of analysis.

3. Rules of Thumb Based on Equipment (Main Plant Items)

Several older UK and North American methods estimate HAZOP duration using Main Plant Items (MPI):

UK-based formulas

-

- Time = (Number of MPIs × 3 hours ) + 3 hours

- Time = (Number of MPI connections × 20 minutes) + 3 hours

The additional 3 hours represents non-HAZOP start-up activities. These methods do not include reporting time.

North American guidance

- 2.5–3.5 hours per MPI

- Total HAZOP effort ≈ 1% of total process design time (poorly defined)

MPI-based methods can be useful as cross-checks, particularly early in projects, but they are generally less intuitive than node-based estimates.

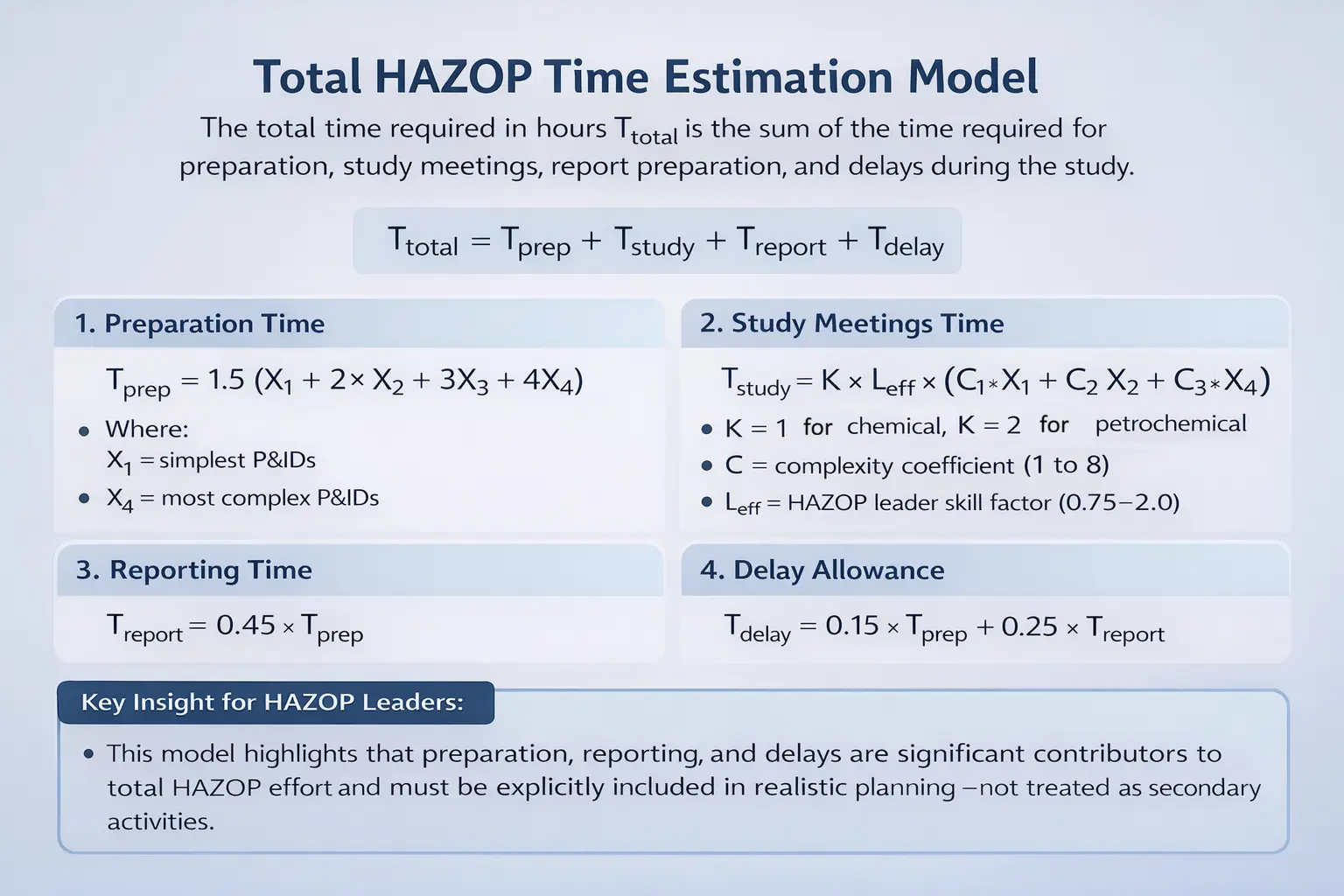

4. More Complex Estimation Methods

More sophisticated models attempt to estimate total HAZOP effort, not just meeting time:

These models account for:

- P&ID complexity

- Type of process (chemical vs petrochemical)

- Experience level of the HAZOP leader

- Explicit allowances for reporting and delays

Example outcomes:

- 20 simple P&IDs → ~20 hours (3–4 days)

- 20 complex P&IDs → ~160 hours (~27 days)

While authors claim 90–95% accuracy, results are highly sensitive to subjective complexity ratings. For this reason, many leaders remain cautious. The real value of these models lies in their explicit recognition that preparation and reporting are major components of total effort, not afterthoughts.

5. Preparation and Reporting Time: Often Underestimated

Preparation and reporting must always be included in the overall estimate—especially for contracted HAZOP leaders.

Common Rule of Thumb (US Guidance)

| Size of HAZOP | Preparation (days) | Reporting (days) |

|---|---|---|

| Small | 1–2 | 3 |

| Medium | 3–4 | 5 |

| Large | 5–7 | 7+ |

These values are optimistic, particularly for complex processes.

Practical Reality

- Node preparation can take 1–2 hours per node

- Comprehensive node descriptions should include:

- Node boundaries

- P&ID references

- Design intent

- Equipment tags

- Operating conditions

- Design limits

Reporting time depends heavily on discipline during the study. Leaders who update records daily and resolve issues promptly can meet these targets; others will exceed them significantly.

Practical Guidance for HAZOP Leaders

In practice, the most robust approach is to:

- Estimate time using multiple methods (P&IDs, nodes, MPI)

- Adjust for process complexity, operating modes, and team capability

- Explicitly include preparation and reporting

- Select the most conservative estimate, not the most optimistic

- Monitor progress early and adjust if required

Certified Functional Safety Professional (FSP, TÜV SÜD), Certified HAZOP & PHA Leader, LOPA Practitioner, and Specialist in SIL Verification & Functional Safety Lifecycle, with 18 years of professional experience in Plant Operations and Process Safety across Petroleum Refining and Fertilizer Complexes.

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain