Petroleum refineries are an essential part of the modern economy, converting crude oil into a range of useful products such as gasoline, diesel, and jet fuel. However, petroleum refineries also generate a variety of pollutants that have significant negative effects on the environment. In this blog, we will explore some of the major environmental concerns, their impacts and control measure associated with petroleum refineries, including air pollution, water pollution, and greenhouse gas emissions.

1. Air Pollution

One of the major concerns associated with petroleum refineries is the release of air pollutants. The refining process produces a wide range of pollutants including sulfur dioxide (SO2), nitrogen oxides (NOx), and particulate matter (PM). These pollutants can have a significant impact on air quality, contributing to the formation of smog and acid rain, and posing a risk to human health. To control air pollution in petroleum refineries, control technologies such as catalytic converters, scrubbers at furnaces stacks, treatment of refinery emissions and selective catalytic reduction (SCR) systems to reduce emissions of SO2 and NOx.

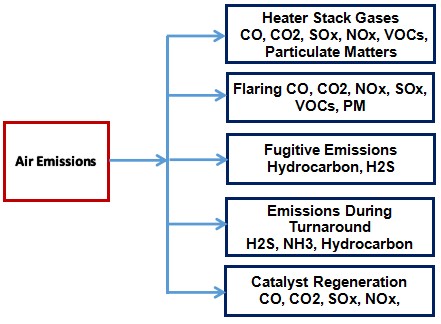

One of the primary sources of air pollution from petroleum refineries is the release of volatile organic compounds (VOCs) during the refining process, furnaces operation, boilers, catalysts regenerations, flaring, storage tanks, petroleum spillage and leakages from process equipment. VOCs are a diverse group of chemicals that can easily evaporate into the air, and they can have a variety of negative health effects. In addition, VOCs can also contribute to the formation of ground-level ozone, a key component of smog. VOCs are also a major contributor to the formation of smog, which can lead to a range of health problems, including respiratory problems, heart disease, and cancer. The diagram shows the sources of air pollution in petroleum refineries.

2. Water Pollution

Water pollution caused by petroleum refineries is a major environmental concern. The refining process generates large quantities of wastewater, which can contain a wide range of pollutants including oil, heavy metals, and toxic chemicals. Petroleum pollution in water significant impact on water quality, posing a risk to aquatic life and drinking water supplies.

One of the major pollutants found in oil refinery wastewater is oil. Oil can be present in the form of oil droplets, emulsions, or dissolved in water. Oil can have a severe impact on aquatic life, suffocating fish and other organisms, and damaging their habitats. The oil can also make its way into drinking water sources, posing a risk to human health.

Another common pollutant found in refinery wastewater is heavy metals. These metals can include lead, zinc, and copper, which can be toxic to aquatic life and can also accumulate in the food chain, posing a risk to human health.

Toxic chemicals such as polycyclic aromatic hydrocarbons (PAHs) and volatile organic compounds (VOCs) are also commonly found in oil refinery wastewater. These chemicals can be carcinogenic and can have a severe impact on aquatic life, as well as on human health.

To mitigate the impacts of water pollution, many refineries have implemented treatment systems such as oil-water separators and biological treatment systems to remove pollutants from the wastewater before it is discharged. These treatment systems use physical, chemical, and biological processes to remove pollutants from the water. For example, oil-water separators use gravity to separate oil droplets from the water, while biological treatment systems use microorganisms to degrade the pollutants.

Overall, water pollution caused by petroleum refineries is a serious environmental concern, which can have a severe impact on aquatic life and human health. However, with the implementation of treatment systems and proper management, the industry can minimize the environmental impact of the refining process on water resources.

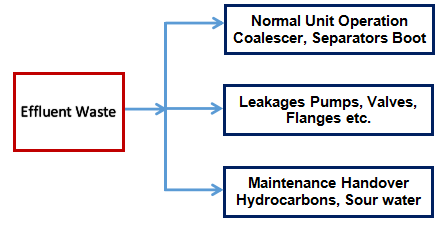

Wastewater sources in petroleum refineries include stripping steam separated from petroleum products, desalting process, sour water treatment, boilers intermittent and continuous blow downs, equipment flushing, floor washing, spent caustic, etc.

3. Greenhouse Gas Emissions

Greenhouse gas emissions from petroleum refineries are a major environmental concern, as they contribute to global warming and climate change. The refining process releases large quantities of carbon dioxide (CO2) and other greenhouse gases into the atmosphere. These emissions can come from a variety of sources including the combustion of fossil fuels in furnaces and boilers, flaring, and chemical reactions during the refining process.

Carbon dioxide (CO2) is the primary greenhouse gas emitted by refineries, accounting for the majority of their greenhouse gas emissions. According to the International Energy Agency (IEA), the oil and gas industry is responsible for around 20% of global energy-related CO2 emissions. Methane (CH4) is another greenhouse gas that is emitted by refineries. Methane is a potent greenhouse gas, with a global warming potential 28 times higher than CO2 over a 100-year time frame. According to the IEA, the oil and gas sector is responsible for around 40% of global methane emissions.

Nitrogen oxides (NOx) and sulfur dioxide (SO2) are also emitted by petroleum refineries, and these emissions contribute to the formation of ground-level ozone, which is a potent greenhouse gas.

To mitigate the environmental impact of greenhouse gas emissions, many refineries are implementing energy efficiency measures to reduce their energy consumption, and some are also exploring the use of renewable energy sources such as solar and wind power to reduce their greenhouse gas emissions.

Additionally, there are international agreements such as the Paris Agreement that aim to reduce greenhouse gas emissions worldwide, and some countries have established carbon pricing mechanisms such as carbon tax and cap-and-trade systems to incentivize industries to reduce their emissions.

4. Hazardous Chemicals

Another environmental concern associated with petroleum refineries is the release of hazardous chemicals during the refining process. These chemicals, such as benzene and toluene, can have severe health effects if they are not properly managed. They can cause damage to the nervous system, lungs, and other organs, and can lead to cancer. In addition to the health risks, these chemicals can also contaminate water sources and damage local ecosystems. It’s crucial for refineries to have proper storage and handling procedures in place to minimize the release of these hazardous chemicals into the environment. Additionally, Regular monitoring and testing of the air, water, and soil surrounding the refineries can help to detect and address any releases of hazardous chemicals.

5. Solid Wastes

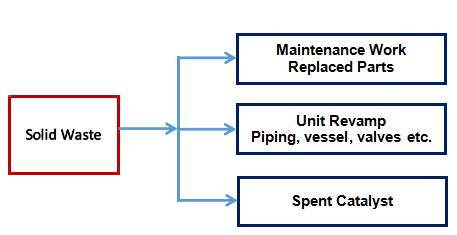

Following are some major sources and control measures of solid wastes in petroleum refineries;

Mechanical wastes like old equipment, valves, or pipes are produced during the replacement of the revamping of the unit. This waste can be minimized by reusing the equipment at other locations. In addition, during revamping avoid unnecessary replacements.

Waste generated from maintenance activities like damaged parts or replacement of disposable parts like coalescing elements, filter cartridges, etc. Avoid the use of disposable parts, if possible use parts that can be reused.

Semi-solid sludge is normally removed from the process vessels during maintenance work in an annual turnaround. There must be a process in the oil refinery to treat the sludge and recover the valuables or can be sold to the contractor for treatment or use. Landfilling must be avoided.

Metals particles due to corrosion in the process may result in the production of tons of solids in a year. Corrosion waste is collected at the reactor catalyst and high-pressure separator. The corrosion rate can be minimized by selecting the best available material for construction or avoiding a corrosive environment.

A huge quantity of spent catalysts is generated depending on the plant’s capacity. Spent catalysts may contain molybdenum, nickel, cobalt, platinum, palladium, vanadium iron, copper and silica, or alumina. Reuse the catalyst as many times as possible after regeneration or rejuvenation.

Top References

- Environmental Control in Petroleum Engineering by John C. Reis

- Petroleum Refining: Technology and Economics by James H. Gary and Glenn E.

- Environmental Impact of the Offshore Oil and Gas Industry” by J.R. Kramer.

- www.epa.gov.com

For further information, discussion and queries please comment in the box below or contact us at admin@ or follow us on Facebook & LinkedIn.