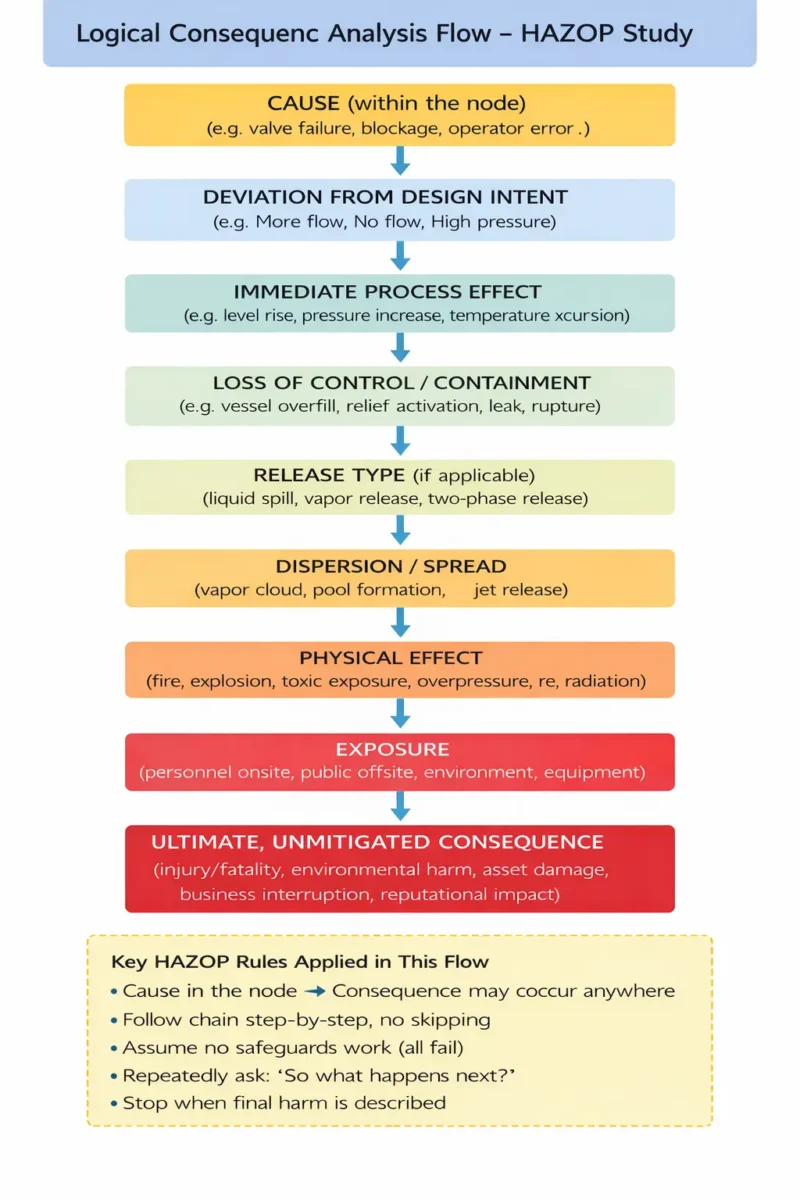

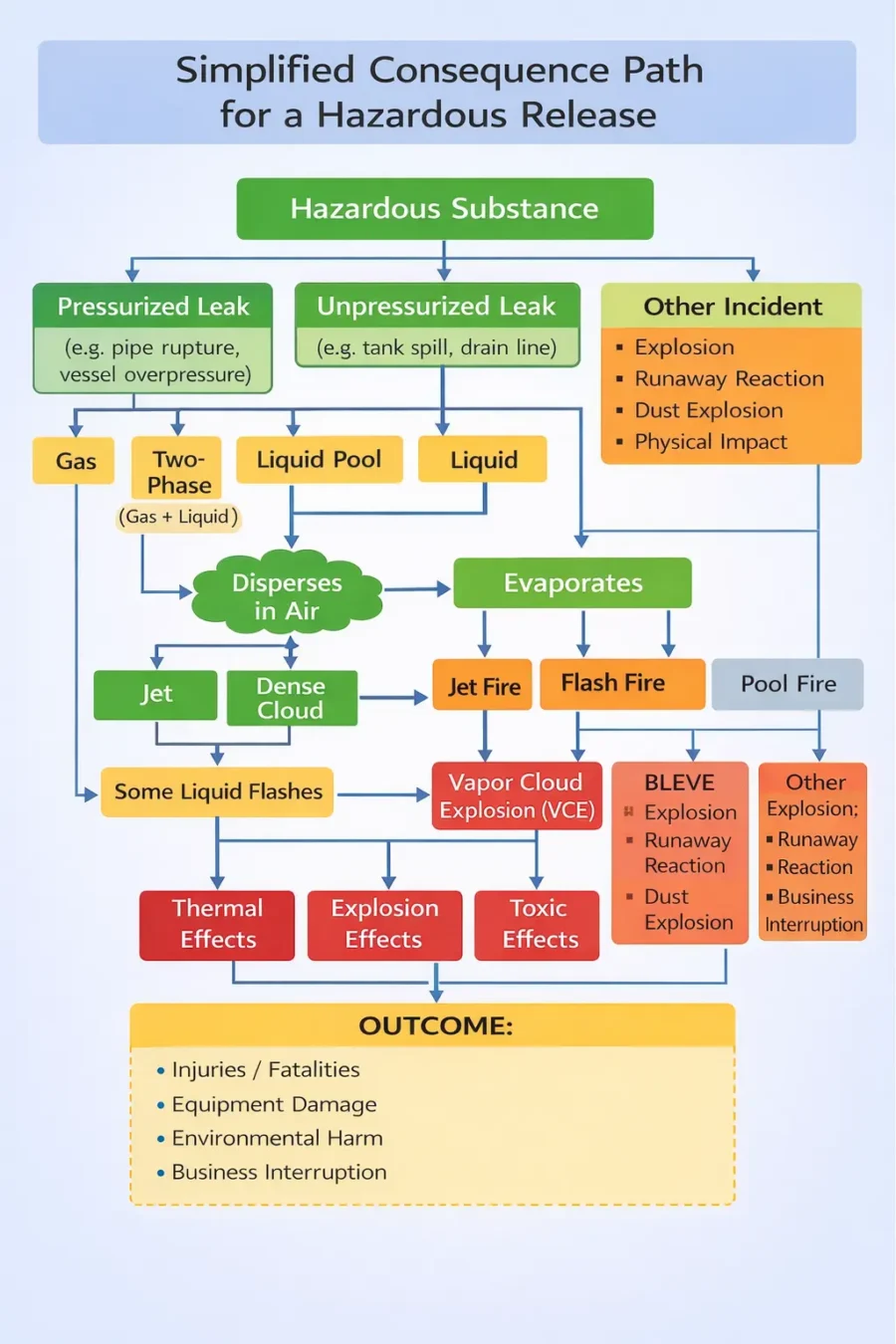

In a HAZOP study, consequence analysis focuses on qualitatively identifying and clearly describing what can happen after a deviation, without calculating frequencies or risk reduction as done in LOPA. The team traces the progression from deviation to loss of containment, dispersion, and physical effects such as fire, explosion, or toxic exposure, and then to the resulting impacts on people, environment, assets, and business.

Following are some guidelines to be considered when estimating consequences in HAZOP study;

1) Assume Ultimate Unmitigated Consequences

When describing consequences, the team should first consider the unmitigated case—i.e., what the deviation could ultimately cause if no safeguards work. This prevents underestimating severity and helps the team later appreciate the true value and importance of existing safeguards.

2) Focus on credibility, not probability

HAZOP consequence assessment is credible scenario building, not probability calculation. In the event that the team develops a scenario with an extremely serious consequence but considers the possibility of it happening very remote, it may be useful to develop a second scenario in which the consequence is less severe but the event is more likely.

3) Apply the HAZOP discipline: “Causes in the node, consequences anywhere”

- Identify causes within the node being studied (to maintain focus).

- Trace consequences wherever they occur, including downstream units and offsite effects.

If consequences lie outside the immediate study section, the leader may either include them immediately or flag and carry them forward—but they must be fully covered, even if distant.

4) Keep the purpose “HAZOP-focused”

Consequence assessment in HAZOP is about qualitatively identifying and clearly describing what can happen after a deviation. The team’s job is to build a credible story of escalation—not to calculate frequencies, PFDs, or risk reduction (that belongs to LOPA). The output should help the reader understand what could happen, how bad it could be, and why safeguards or recommendations may be needed.

5) Start from the deviation and follow the Logical escalation path

For each deviation, the team should trace consequences in a logical sequence, step by step typically:

Deviation → process upset → Immediate Process Effect → loss of containment → dispersion/spread → physical effects → exposure → harm (Ultimate Unmitigated Effect).

The leader should drive the discussion using “So what happens next?” until the team reaches the final harmful outcome, not just an intermediate event.

6) Use Primary loss of containment as the most common consequence pathway

In process plants, many severe outcomes are driven by loss of containment of hazardous material or energy (e.g., vessel leak, pipeline rupture, relief valve lifting). When loss of containment is credible, the team should consistently consider:

- Nature of the release

- Dispersion/spread

- Fire/explosion/toxic outcomes

- Impacts and losses

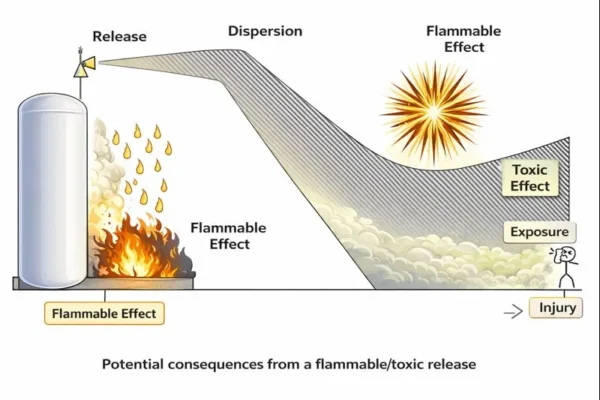

7) Describe the nature of the release before jumping to fire/explosion/toxic outcomes

When a release is possible, first define what is released and how:

- Phase/form: gas, liquid, solid, or two-phase

- Condition: pressurized vs non-pressurized

This matters because it determines the likely behavior—jetting, pooling, flashing, rapid dispersion—and therefore the realistic consequence outcomes.

8) Cover flammable release outcomes in a structured way

If the material is flammable, the team should consider ignition timing and release conditions:

- Immediate ignition of pressurized gas/two-phase release → jet fire

- Delayed ignition after dispersion → flash fire and/or vapor cloud explosion

- Liquid spill ignition → pool fire (sustained thermal radiation)

Where credible, include specific outcomes such as BLEVE and explosion escalation possibilities, and describe how the scenario can progress.

9) Cover toxic release outcomes for onsite and offsite receptors

If the material is toxic, consequences should address exposure to harmful concentrations for:

- Plant personnel and contractors (onsite)

- Public (offsite)

The description should reflect dispersion behavior and the potential for exposure duration and affected area, without needing detailed modeling at HAZOP stage.

10) Identify the key physical effects that create harm

The team should explicitly name the physical effects, because these are the direct harm mechanisms:

- Thermal radiation from fires

- Overpressure from explosions

- Toxic concentration from releases

These effects should then be linked to impacts on people, environment, and assets.

11) List consequences for each cause—don’t stop at “release”

For every cause, record consequences across the realistic range, such as:

- Leakage / loss of containment / toxic dispersion

- Fire and explosion outcomes (pool fire, jet fire, flash fire, VCE, BLEVE)

- Injury or fatality

- Equipment/property damage

- Production/material loss and downtime

- Product quality/specification impact

This makes the record complete and avoids missing business-critical consequences.

12) Consider all impact categories, not only safety

Consequence descriptions should cover:

- People: workers, contractors, and offsite population

- Environment: releases, contamination, long-term harm

- Assets: equipment damage, structural damage, secondary failures

- Business impact: shutdown, loss of capacity, delays

- Financial impact: repair cost, lost production

- Non-financial impact: reputation, regulatory action, public confidence

Many organisations require these categories, and they strengthen severity ranking and recommendations

13) Document consequences as a clear narrative that a reader can follow

Consequence write-ups should read like a short, logical story so any reader can understand the escalation path and the reason a recommendation exists. Clear narratives support:

- Strong, defensible HAZOP recommendations

- Better decision-making and prioritization

- Easier follow-up studies (including LOPA) if required

Top References:

- Layer of Protection Analysis Simplified Risk Assessment by Center for Chemical Process Safety

- The HAZOP Leader’s Handbook by PHIL EAMES

- HAZOP: Guide to Best Practice Frank Crawley & Brian Tyler

Certified Functional Safety Professional (FSP, TÜV SÜD), Certified HAZOP & PHA Leader, LOPA Practitioner, and Specialist in SIL Verification & Functional Safety Lifecycle, with 18 years of professional experience in Plant Operations and Process Safety across Petroleum Refining and Fertilizer Complexes.

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain