A steam turbine is a machine that move a rotating shaft by converting the thermal energy from pressurized steam into kinetic energy, which is subsequently changed into mechanical energy. The basic design of a steam turbine involves a rotor with blades attached to a central shaft. When steam is introduced into the turbine, it flows over the blades, causing them to rotate. The rotating blades are then connected to a generator, which produces power.

Working Principle of Steam Turbine

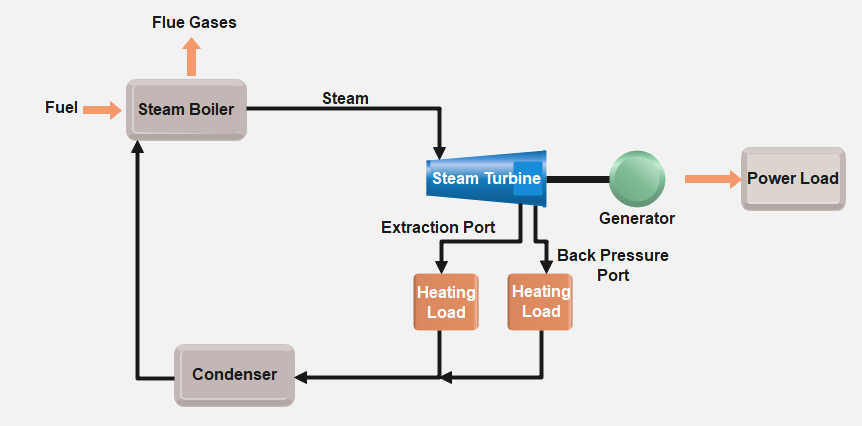

The Rankine cycle, a thermodynamic cycle that defines the process of transforming thermal energy into mechanical energy, serves as the framework for a steam turbine’s operation. The Rankine cycle is made up of a boiler, a turbine, a condenser, and a pump.

The process begins with the boiler, where water is heated to produce steam. The steam then enters the turbine, which is made up of multiple stages of blades mounted on a rotor. As the steam flows over the blades, it causes the rotor to spin, generating mechanical energy.

The mechanical energy is then transferred to a generator, where it is converted into electrical energy. After passing through the turbine, the steam is cooled and condensed back into the water in the condenser and then returned to the boiler to be heated again.

The pump is responsible for circulating the condensed water from the condenser back to the boiler, completing the Rankine cycle.

Types of Steam Turbines

There are several types of steam turbines, each designed to meet specific requirements for power output, efficiency, and operating conditions. Here are some common types of steam turbines:

1. Impulse Turbines

Impulse turbines consist of a set of blades arranged in a circular pattern around a central shaft. The blades are curved to redirect the flow of water or steam, causing the turbine to rotate. The water or steam is directed onto the blades by a set of nozzles or jets, which are positioned at the periphery of the turbine. They are typically used in applications where high speed is required, such as in small-scale power plants.

2. Reaction Turbines

Reaction turbines consist of a set of curved blades arranged in a circular pattern around a central shaft. The blades are shaped in such a way that the water or steam flows over them, causing a reaction force that rotates the turbine. Unlike impulse turbines, reaction turbines do not use nozzles or jets to direct the flow of water or steam onto the blades. They are typically used in larger power plants where high efficiency is required.

3. Condensing Turbines

In a condensing turbine, steam is supplied to the turbine from a boiler or other source. The steam is then directed onto a set of turbine blades, where it expands and rotates the turbine. The steam is then directed into a condenser, where it is cooled and condensed back into water. The condensed water is typically returned to the boiler to be reused. They are typically used in large-scale power plants to maximize efficiency.

4. Non-Condensing or Back Pressure Turbines

In a non-condensing turbine, steam is supplied to the turbine from a boiler or other source. The steam is then directed onto a set of turbine blades, where it expands and rotates the turbine. The steam is then exhausted to the atmosphere or another low-pressure system. These turbines do not require a vacuum and operate with steam that is still in its gaseous state. They are typically used in smaller power plants or industrial applications.

5. Extraction Turbines

In an extraction turbine, steam is supplied to the turbine from a boiler or other source. The steam is then directed onto a set of turbine blades, where it expands and rotates the turbine. At the intermediate stages of the turbine, some of the steam is extracted and used for other purposes, such as process heating or power generation.

6. Reheat Turbines

In a reheat turbine, steam is supplied to the turbine from a boiler or other source. The steam is then directed onto a set of turbine blades, where it expands and rotates the turbine. The steam is then reheated and directed onto a second set of turbine blades, where it expands further and rotates the turbine again. The steam is then exhausted to a condenser or another low-pressure system.

Top References

- https://www.researchgate.net

- https://www.sciencedirect.com

- Breeze, “Steam Turbine Combined Heat and Power Systems,” Combined Heat and Power