Quantitative Risk Assessment (QRA) is a useful tool for ensuring process safety in high-risk industries like chemical manufacturing, oil and gas and petroleum refining. By using data, mathematical models and structured analysis, it has the ability to identify potential hazards, quantify their likelihood and evaluates their consequences to prevent accidents and ensure safer operations and compliance with regulations. Whether you are designing a new facility, managing daily operations or investigating an incident, it provides a clear way and precision needed to make safety decisions. It reduces risks effectively and protects workers, assets and environment from dangerous incidents.

What is Quantitative Risk Assessment?

Quantitative Risk Assessment method is a well-structured numerical approach to risk management. It uses different approaches like mathematical models, statistical data and computational tools to assess different risks in industrial processes. It simply assigns precise numerical values to both the probability of hazardous events like leaks, fires or explosions and their potential impacts. In this way it allows for a measurable evaluation of risks by enabling a better decision making.

QRA is able to answer the following three fundamental questions:

- What can go wrong? It identifies potential hazards that can be happen like equipment failures, human errors and external events.

- How likely is it to happen? It estimates the frequency and the probability of these events by using historical data and predictive models.

- What are the consequences? It then quantifies the potential impacts from these events such as injuries, environmental damage and financial losses.

QRA is widely followed by the industries governed by strict safety regulations such as OSHA’s Process Safety Management (PSM) standards to prevent hazardous incidents. It helps industries to prioritize safety measures and allocate resources effectively by providing a clear and evidence-based framework.

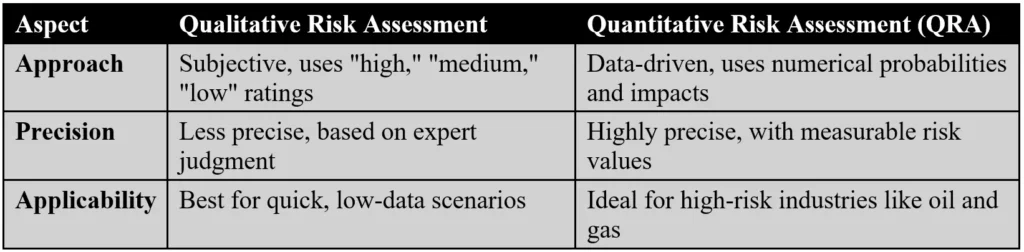

What is Difference Between Quantitative Risk Assessment and Qualitative Risk Assessment?

Quantitative Risk Assessment (QRA) uses numbers and data to measure the likelihood and impact of risks like calculating the chance of a gas leak in a refinery. It is precise and ideal for complex industries. Qualitative risk assessment, on the other hand, relies on expert opinions to describe risks as “high,” “medium,” or “low” without specific numbers. It is simpler but less detailed and better for quick evaluations where data is limited.

Why is Quantitative Risk Assessment Essential in the Process Industry?

The potential for catastrophic incidents is present all the time in high-risk industries like chemical manufacturing, oil refineries and gas processing facilities. Even a single failure such as a valve malfunction or operator oversight can lead to devasting consequences. These can include loss of life, environmental harm and significant financial losses. In these scenarios QRA plays a critical role in a systematic way to:

- Identify Hazards: Detect potential risks, such as equipment breakdowns, process deviations from set limits and external threats like natural disasters.

- Quantify Impacts: Calculate the severity of potential incidents such as the radius of a fire, the spread of a toxic gas cloud and downtime costs.

- Inform Decisions: Provide guides in safety systems such as emergency shutdown valves, fire suppression systems and enhanced training programs.

- Ensure Compliance: Meet regulatory requirements such as OSHA’s PSM or environmental standards by demonstrating proactive risk management.

- Prevent Incidents: Reduce the likelihood of accidents by identifying and addressing high-risk scenarios before they can occur.

By providing a statistical data QRA empowers process safety engineers, managers and operators to make such decisions that can enhance safety, protect the communities around and also maintain operation reliability.

Example of Quantitative Risk Assessment

For example, consider a chemical plant handling flammable gases, QRA can assess the risk of a gas leak leading to an explosion, estimate its likelihood based on equipment failure rates and recommend mitigation measures like blast-resistant barriers or automated isolation systems.

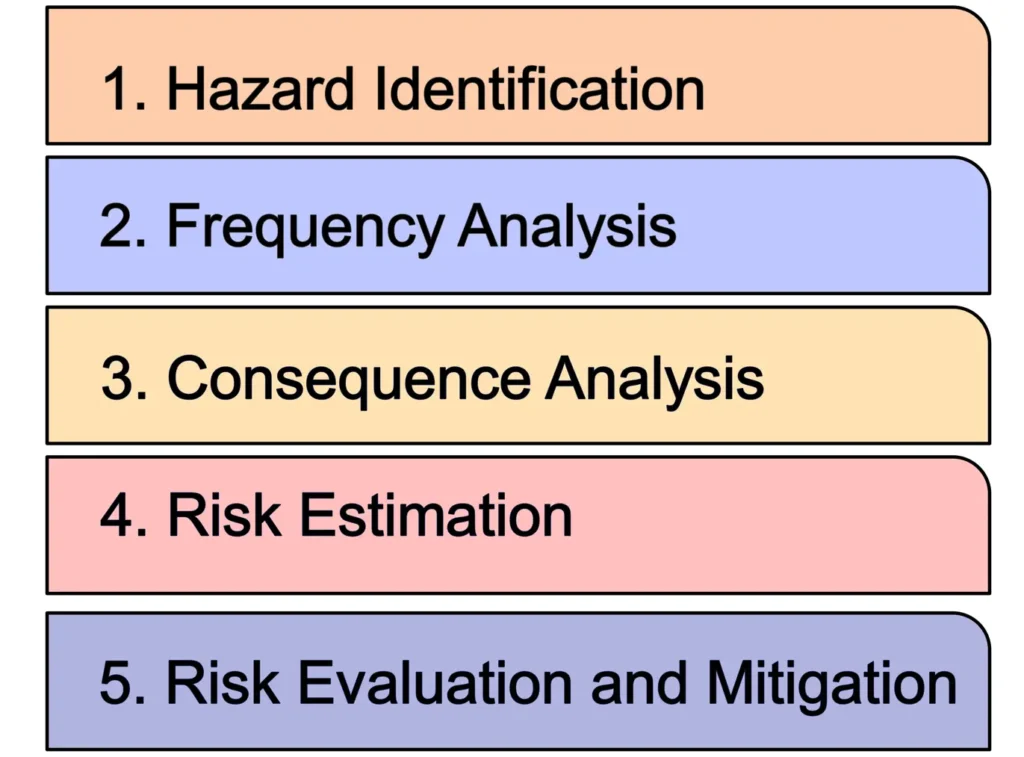

How Does Quantitative Risk Assessment Work?

The Quantitative Risk Assessment technique has a systematic procedure containing multi step methodology to identify, analyze and mitigate risks. Following is a detailed breakdown of each step:

- Hazard Identification: This initial step involves pinpointing potential hazards in the process system. Techniques like Hazard and Operability Study (HAZOP), Failure Modes and Effects Analysis (FMEA) and What-If Analysis are used to identify risks such as equipment failures, human errors and external events (e.g., floods or earthquakes). For instance, a HAZOP study might reveal that a pressure vessel could fail due to corrosion.

- Frequency Analysis: Using historical data, industry databases and statistical models, QRA estimates the likelihood of each identified hazard occurring. For example, if a pump has a failure rate of 0.01 per year based on historical records, QRA uses this data to calculate the probability of a failure related incident in future.

- Consequence Analysis: This step quantifies the potential impact of a hazardous event. Advanced modeling tools such as computational fluid dynamics (CFD) or dispersion models simulate scenarios like gas releases, fires and explosions. For instance, QRA might calculate the blast radius of an explosion or the area affected by a toxic gas cloud. These include impacts on personnel, equipment and the environment.

- Risk Estimation: By combining frequency and consequence data, QRA calculates the overall risk level. This is often expressed as an annual probability of harm (e.g., fatalities per year) or visualized through risk contour maps which show the geographical spread of risks around a facility. Risk levels are compared against acceptable thresholds such as those set by regulatory bodies.

- Risk Evaluation and Mitigation: If risks exceed acceptable levels, then QRA recommends mitigation measures such as installing safety instrumented systems (SIS), improving maintenance schedules or redesigning processes to reduce hazards. The goal is to bring risks within acceptable limits while balancing costs and feasibility.

This whole process ensures that risks are not only identified but also prioritized and addressed with targeted solutions and also making operations safer and more reliable.

Applications of Quantitative Risk Assessment in the Process Industry

Quantitative Risk Assessment is a versatile tool with wide range of applications in the process industry. Following are some of main areas where it is used:

- Facility Design and Layout: During the design phase of a chemical plant or refinery, QRA helps engineers to optimize layouts to minimize risks. For example, it can suggest the safest placement of storage tanks to reduce the impact of a potential fire or explosion.

- Operational Safety: QRA informs day to day operations by identifying critical safety measures such as regular equipment inspections, operator training and emergency response protocols. For instance, QRA might recommend more frequent maintenance for a high-risk compressor or any other equipment.

- Incident Investigation and Learning: After an incident, QRA analyzes root causes and quantifies the risks that led to the event. This helps develop preventive measures for future such as redesigning a process or upgrading safety systems to avoid recurrence.

- Regulatory Compliance and Reporting: QRA provides documented evidence of risk management which is essential for complying with standards like OSHA’s PSM, EPA regulations and international guidelines like those from the Center for Chemical Process Safety (CCPS).

- Emergency Planning: QRA provide supports for the development of emergency response plans by identifying worst case scenarios and their potential impacts. For example, it can estimate evacuation zones in case of a toxic gas release.

A practical example is in an oil refinery where QRA might assess the risk of a specific pipeline rupture. By calculating the likelihood of a leak and its potential to cause a fire, QRA could recommend installing automated isolation valves or increasing inspection frequency to mitigate this risk.

Benefits and Challenges of Quantitative Risk Assessment

Benefits

- High Precision: QRA’s reliance on numerical data and models provides accurate risk estimates and as a result reducing uncertainty compared to qualitative methods.

- Cost-Effective Resource Allocation: By prioritizing high-risk scenarios QRA ensures some safety investments like installing safety barriers or upgrading equipment and also are focused where they are needed most.

- Enhanced Safety: Quantifying risks helps prevent incidents, protecting workers and communities and the environment from any kind of dangerous harm.

- Regulatory Alignment: QRA demonstrates compliance with safety standards helping organizations to avoid penalties and maintain a strong safety record.

- Decision Support: QRA provides clear and proper data insights that guide strategic decisions from facility design to operational improvements.

Challenges

- Data Dependency: QRA requires reliable and high-quality data which may be scarce for new processes or facilities with limited operational history.

- Technical Complexity: The use of sophisticated models and software, such as fault tree analysis or CFD, demands skilled professionals with specialized training.

- Resource Intensity: Conducting a comprehensive QRA can be time consuming and costly particularly for smaller organizations with limited budgets.

- Uncertainty in Assumptions: QRA relies on assumptions (e.g., failure rates or environmental conditions) which can introduce uncertainty if not carefully validated.

Even though there are some challenges as well but QRA is still a valuable tool that helps to manage risks in high-risk industries.

References:

- Crowl, D. A., & Louvar, J. F. (2011). Chemical Process Safety: Fundamentals with Applications. Prentice Hall.

- Faisal Khan, Hans J. Pasman, Ming Yang, Methods to Assess and Manage Process Safety in Digitalized Process System, Academic Press, 2022.

- Guidelines for Chemical Process Quantitative Risk Analysis, 2nd Edition, CCPS, John Wiley & Sons, Inc., 2000.

- Sutton, I. (2010). Process Risk and Reliability Management: Operational Integrity Management. William Andrew.

- Rausand, M. (2011). Risk Assessment: Theory, Methods, and Applications. Wiley-Blackwell.