Petroleum coke, also known as petcoke is a byproduct of the refining process of crude oil. It is a carbon-rich solid material that is used for various industrial and commercial purposes, such as fuel in power plants and cement kilns. Petcoke can vary in appearance from black, to dark grey, to golden brown, depending on its composition and the refining process used to produce it. The sulfur content of petcoke can also vary widely, with some grades having very low sulfur content, while others have very high sulfur content.

Petcoke is derived from a final thermal cracking process base Coker units that split long-chain hydrocarbons of petroleum residues into shorter chains. Petcoke is also produced in the production of synthetic crude oil (syncrude) from bitumen extracted from Canada’s oil sands and from Venezuela’s Orinoco oil sands.

In petroleum coker units, residual oils from other distillation processes used in petroleum refining are treated at a high temperature and pressure leaving the petcoke as a byproduct. In a delayed coker, the residue is thermally cracked to produce lighter, more desirable products. In the process, a significant portion of the feed (~15% of volume) is converted into elemental carbon called petroleum coke. Petroleum refiners separate coke from the other coker products and sell it as a product.

Petroleum coke (petcoke) prices can vary depending on factors such as the type of petcoke, the location and the market conditions. The prices are also influenced by supply and demand, as well as transportation costs and taxes.

[amazon_auto_links id=”3259″]

Types of Petroleum Coke

There are two main types of petroleum coke: green coke and calcined coke.

1. Green Coke

Green coke is the raw material used to produce calcined coke. It is the solid carbon byproduct of the oil refining process. Green coke has a high moisture and volatile matter content.

2. Calcined Coke

Calcined coke is the product from the “calcining” of green coke. Calcining is the process of heating green coke to remove moisture and volatile matter and to increase the carbon content. Calcined coke has a lower moisture and volatile matter content, and a higher carbon content than green coke.

Depending on the end-use of the coke, some additional classifications can also be made:

3. Fuel-grade coke

Fuel-grade coke is used as fuel in power plants, cement kilns, and other industrial facilities. It is typically high in sulfur and heavy metals. The Fuel-grade coke is further classified as either sponge coke or shot coke morphology. In general, lower temperatures and higher pressures promote sponge coke formation.

4. Anode-grade coke

Anode-grade coke is used in the production of aluminium and other non-ferrous metals. It is typically low in sulfur and heavy metals.

Petroleum Coke Formula

Petroleum coke is a complex mixture of various hydrocarbons and impurities, so it does not have a specific chemical formula. It is primarily composed of carbon and hydrogen, but also contains small amounts of sulfur, nitrogen, and other elements. The chemical composition of petroleum coke can vary depending on the type of crude oil and the refining process used to produce it.

It is worth mentioning that, The chemical formula for calcined petroleum coke is CxHy, where x is the number of carbon atoms and y is the number of hydrogen atoms in the molecule

Petroleum Coke Uses

Petroleum coke (petcoke) is a carbon-rich solid material that is used for various industrial and commercial purposes. Some of the most common uses of petcoke include:

- Fuel: Feul grade coke represents ~ 80 % of the worldwide petroleum coke produced and is used as fuel in electric power plants, cement kilns, and other industrial facilities. Further, Calcined petcoke is also used in lime production and as a substitute for fuel oil in brick and glass manufacturing.

- Aluminium, Graphite Electrodes Manufacturing: Calcining the coke, by heating it in a rotary kiln at temperatures over 1370 °C, increases the carbon content of the coke thus making it suitable, (generally less than 2 wt% sulfur and less than 0:5% ash content), for use in the aluminium, graphite electrode, steel, titanium dioxide, and other carbon consuming industries.

Petcoke is used in the production of anodes, which are used in the aluminium and steel industries. - Anodes Production: Needle coke is used to produce the electrodes used in electric arc furnace (EAF) steel production. No other material has needle coke’s combination of electrical conductivity and physical properties required for EAF electrodes, making it a high-value product.

- Carbon Products: Petcoke can be processed to produce various carbon products, such as activated carbon and synthetic graphite.

- Asphalts production: Petcoke is used as a feedstock to produce asphalt, which is used in the construction of roads and buildings.

- Chemicals Production: Chemicals like methanol, formaldehyde, and acetic acid may all be made from petcoke.

- Construction: In the construction of the building, petcoke serves as a filler in asphalt and a component in bricks.

[amazon_auto_links id=”3259″]

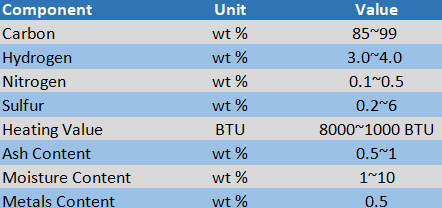

Specifications of Petroleum Coke

Petroleum coke (petcoke) specifications vary depending on the intended use of the product and the type of petcoke being produced. Some of the most common specifications for petcoke include:

- Chemistry: Most petcoke consists of carbon 85~99%, and hydrogen in concentrations between 3.0- 4.0%. Raw (or green) coke contains between 0.1- 0.5% nitrogen and 0.2- 6.0% sulfur which become emissions when coke is calcined.

- Heating Value: Petcoke is highly combustible and has a high heating value, often between 8,000 and 10,000 BTU/lb.

- Size: Typically, the particle sizes of petcoke is typically in the range of 0-50 mm.

- Ash: Depending on its origin, petcoke’s ash level may range from 0.5~1%.

- Moisture: Depending on where it was mined, petcoke’s moisture content may range from far under 1% to well over 10%.

- Volatile Matter Content: The volatile matter concentration of petcoke is typically less than 10%, depending on where it was mined.

- Hardness: There are two distinct varieties of petcoke: calcined and uncalcined. Calcined petcoke is harder and denser than regular petcoke due to its increased carbon concentration.

- Sulfur Content: Petcoke sulfur content can vary from 0.2% to 6%, depending on the type of petcoke and the refining process used. Anode-grade petcoke typically has a lower sulfur content than fuel-grade petcoke

- Metal Content: Petcoke metals Aluminium, Boron, Chromium, Calcium, Cobalt Iron etc. These are present in weight ppm but total metals content is typically less than 0.5%.

- Fixed Carbon: Petcoke fixed carbon content is typically more than 85% and can be as high as 99%.

- Real Density: Petcoke real density is typically in the range of 0.8 to 1.0 g/cm3.

Petroleum Coke Suppliers

There are several places to purchase petcoke from across the globe.

Oil refineries: Petcoke is a byproduct of the oil refining industry and is sold to a wide range of commercial and industrial users.

Trading companies: Several firms exist solely for the purpose of trading commodities like petcoke.

Mining companies: Petcoke is a byproduct of oil sand mining, and it is sold to a wide range of commercial and industrial clients.

Importers and exporters: As a result, there are businesses whose only focus is bringing and sending petcoke across nations.

Petcoke manufacturers: Calcined petcoke, made by heating green petcoke to eliminate moisture, volatile matter, and impurities and to boost its electrical conductivity, is a product made by certain firms

Difference Between Petroleum Coke and Coal

Petroleum coke and coal are both fossil fuels, but they are made from different sources and have different properties. Petroleum coke, also known as petcoke, is a byproduct of the oil refining process. It is made from heavy crude oil that has been distilled to remove lighter components, leaving a heavy, high-carbon residue. Coal, on the other hand, is a naturally occurring sedimentary rock that is primarily composed of carbon.

In terms of energy content, petcoke has a higher heating value than coal. Petcoke also has a higher sulfur content than coal, which can be a concern for air quality. However, petcoke can also be used as a source of carbon for industrial processes, such as the production of aluminum and other metals.

Top References:

- www.wikipedia.com

- www.sciencedirect.com

- www.mckinseyenergyinsights.com

- Springer Handbook of Petroleum Technology by Chang Samuel Hsu, Paul R. Robinson (Eds.)

For further information, discussion and queries please comment in the box below or contact us at admin@ or follow us on Facebook & LinkedIn.

5 thoughts on “Petroleum Coke Types, Uses and Specifications”

A concise description which a technical person can appreciate.

Dear Mr./Mrs.

For the Turkmenistan oil company we are consulting;

A mixture of coke ore Vanadium, Ferrum, silicon, nickel and sodium used in the manufacture of welding electrodes is required.

can you make an offer? We are planning to buy 30-40 tons per month.

Kind regard’s

Hi Birol,

this is Madeline at Simosa company, we are specialized in trading petcoke from Taiwan to other countries. If you have demand of petcoke please feel free to contact me at madeline_chen@simosa.com.tw thanks

What is the difference between 2A and 3A GPC

We Obar Oilfield Services Pvt. Ltd is a supplier of Law Sulpher Calcined Petroleum Cocke. We can supply 100,000 Mertice Tons of CPC. early. For your CPC requirement please contact us.