Deaerators are vital for keeping steam power plants running smoothly. By stripping out corrosive gases and preheating feedwater, they protect boilers, boost efficiency, and extend equipment life. In this blog, we’ll break down the working principle of deaerators, explore their different types, and the process control strategies.

What Is a Deaerator and Why Does It Matter?

A deaerator works with boiler feedwater, stripping out harmful gases like oxygen and carbon dioxide. These gases, if left in the water, can corrode boiler tubes, pipelines, and other equipment, leading to costly repairs and downtime. Deaerators are the main equipment of steam power plants, ensuring the feedwater is clean, preheated, and ready for the boiler.

Key Benefits of Deaerators

- Corrosion Prevention: Removes oxygen and carbon dioxide to protect metal surfaces from pitting and acid damage.

- Efficiency Boost: Preheats feedwater, reducing the energy needed to produce steam.

- Equipment Protection: Ensures a steady supply of feedwater and prevents pump cavitation by maintaining proper pressure.

- System Reliability: Supports continuous operation by delivering high-quality feedwater.

Why Deaeration Is Critical

Dissolved gases in feedwater can cause trouble. Oxygen causes pitting corrosion, creating small, deep holes that weaken boiler components. Carbon dioxide forms carbonic acid when dissolved in water, lowering the pH and accelerating metal degradation. Maintaining a pH above 8.5–9.0 helps, but chemical treatments like sodium sulfite or hydrazine alone are expensive and risky if overdosed. Deaerators offer a mechanical solution, reducing dissolved oxygen to as low as 7 parts per billion (ppb), making them both cost-effective and efficient when paired with minimal chemical dosing.

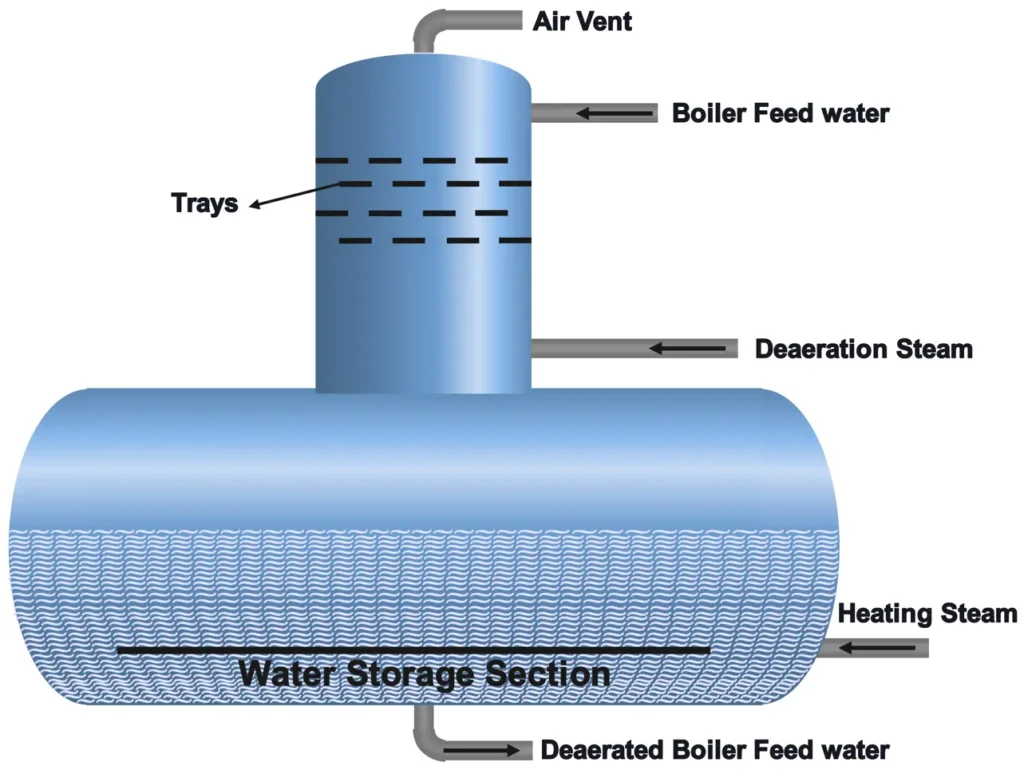

How Does a Deaerator Work?

The deaerator lies on two scientific principles: Henry’s Law and the temperature effect on gas solubility. Henry’s Law tells us that gases dissolve less in a liquid when the pressure above the liquid drops. Meanwhile, as water approaches its boiling point, gas solubility reduces to near zero. Deaerators create the perfect environment to exploit these principles.

Step-by-Step Process

- Feedwater Entry: Cold or partially heated feedwater (often from low-pressure heaters or condensate systems) enters the deaerator.

- Water Breakup: The feedwater is sprayed through nozzles or cascaded over trays, breaking it into fine droplets or thin films to maximize surface area.

- Steam Heating: Low-pressure steam (from turbine extraction or auxiliary sources) is injected, heating the water to its saturation temperature (typically 104–116°C or 220–240°F for smaller units).

- Gas Release: As the water heats up, dissolved gases like oxygen and carbon dioxide are released and carried away by excess steam.

- Venting: The gases are vented to the atmosphere through a vent condenser, which recovers vapor while letting gases escape.

- Storage: The deaerated water collects in a storage tank, ready to be pumped to high-pressure heaters or the boiler.

A thick steam layer above the storage tank prevents gases from re-dissolving, ensuring the feedwater stays clean. Some deaerators can remove carbon dioxide entirely and reduce oxygen to trace levels.

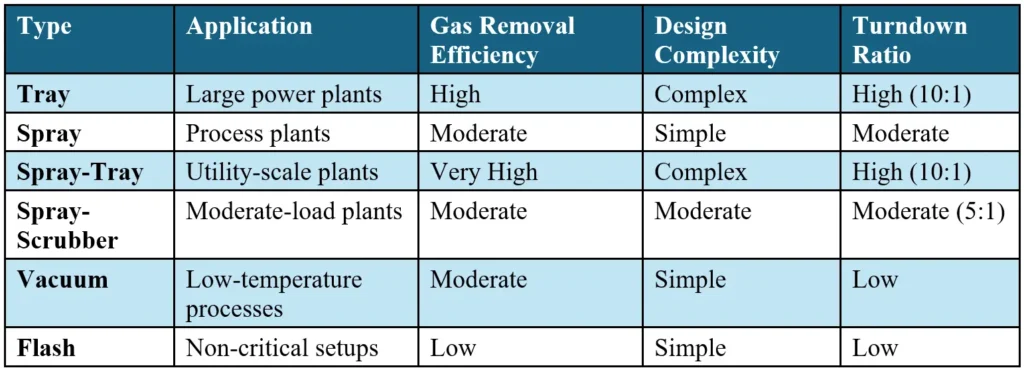

Types of Deaerators

Deaerators come in various designs, each based on specific plant needs. Here are the main types, along with their pros and cons:

1. Tray-Type Deaerator

- How It Works: Feedwater flows over a series of trays with small holes, forming droplets or thin films that interact with upward-flowing steam. The prolonged contact time ensures thorough gas removal.

- Advantages:

- Highly efficient, ideal for plants with high turndown ratios (ability to handle varying loads).

- Achieves very low oxygen levels (e.g., <7 ppb).

- Challenges:

- Complex design, making it more expensive.

- Trays can be damaged by pressure fluctuations, requiring careful control.

- Best Use Case: Large power plants with fluctuating loads.

2. Spray-Type Deaerator

- How It Works: Feedwater is sprayed through nozzles or hits baffle plates, breaking into fine droplets that mix with steam for rapid heating and gas release.

- Advantages:

- Simple, compact design, often used in smaller process plants.

- Quick response to load changes.

- Challenges:

- Less effective for high turndown ratios compared to tray types.

- May need additional heating for optimal performance.

- Best Use Case: Industrial plants with moderate steam demands.

3. Spray-Tray Deaerator

- How It Works: Combines spraying and tray cascading. Feedwater is first sprayed into a steam-filled chamber, then flows over trays for final deaeration.

- Advantages:

- Best of both worlds: high efficiency and flexibility.

- Widely used in modern utility-scale plants.

- Challenges:

- More complex than spray-only designs.

- Best Use Case: High-pressure power plants requiring top-tier efficiency.

4. Spray-Scrubber Deaerator

- How It Works: Feedwater is sprayed, then passes through a scrubber section where turbulent mixing with steam strips residual gases.

- Advantages:

- Cost-effective compared to tray types.

- Suitable for moderate load variations (5:1 turndown ratio).

- Challenges:

- Less flexible than spray-tray designs (10:1 turndown ratio).

- Best Use Case: Plants with stable loads and budget constraints.

5. Vacuum Deaerator

- How It Works: Operates under low pressure, boiling water at lower temperatures (e.g., 26°C or 79°F at 29” Hg) to enhance gas removal without extensive heating.

- Advantages:

- Energy-efficient for low-temperature applications.

- Challenges:

- Rare in boiler plants due to limited effectiveness for high-pressure systems.

- Best Use Case: Specialized low-temperature processes.

6. Flash Deaerator

- How It Works: Heats water above 100°C (212°F) and sprays it into an open tank, flashing some water into steam to remove gases.

- Advantages:

- Simple design.

- Challenges:

- Less effective, not recommended for critical applications.

- Best Use Case: Non-critical, low-budget setups.

Process Control: Keeping Deaerators in Check

They need precise control to maintain optimal performance, especially during startups, low loads, or sudden load changes.

1. Pressure Control

- Goal: Keep the deaerator at the right pressure to maintain saturation temperature, maximizing gas removal.

- How It Works:

- Cold Startup: Auxiliary steam (1.5 bar for large units, 0.8 bar for smaller ones) heats the deaerator.

- Low Load/Hot Startup: Cold reheat (CRH) steam (3.5 bar) takes over if available.

- High Load (>55%): Extraction steam (up to 8 bar) from the turbine handles heating, with pressure varying based on load.

- Control Loops:

- Basic: Separate loops for auxiliary steam (1.5 bar setpoint) and CRH steam (3.5 bar setpoint). The auxiliary valve closes when CRH is sufficient.

- Advanced: An integrator circuit prevents rapid pressure drops during load throw-off, adjusting setpoints gradually (e.g., 0.5 bar/min).

2. Level Control

- Goal: Maintain a stable water level to ensure a steady feedwater supply and prevent pump cavitation.

- How It Works:

- Direct Control: The main condensate valve after the condensate extraction pump modulates the condenser hot-well level, while a dump valve (to a reserve tank) or makeup valve regulates the deaerator level.

- Indirect Control: The main condensate valve controls the deaerator level, with makeup or dump valves managing the condenser.

- Three-Element Control (Large Plants): Monitors deaerator level, total outflow and total inflow for precise regulation.

3. Temperature Control

- Goal: Keep feedwater above 100°C (212°F, or 95°C in high-altitude areas) to ensure effective gas release.

- How It Works: Steam injection is adjusted, often using flash tank steam during startup to replace auxiliary steam, optimizing heat recovery.

People Also Asked Questions with Answers

Why is oxygen removal critical in boilers?

Oxygen causes pitting corrosion, creating small holes that weaken boiler tubes and reduce system lifespan. Deaerators remove oxygen to protect equipment and ensure reliable operation.

What’s the difference between spray and tray deaerators?

Spray deaerators use nozzles to break water into droplets, while tray deaerators cascade water over trays for extended steam contact. Tray types are more efficient for large plants with varying loads.

How does a deaerator prevent pump cavitation?

By elevating the deaerator, it provides sufficient pressure (NPSH) at the boiler feed pump suction, preventing the feedwater from flashing into vapor and damaging the pump.

Why is process control important for deaerators?

Precise control of pressure, level, and temperature ensures efficient gas removal, prevents equipment damage, and maintains system reliability.

References

- Swapan Basu & Ajay Kumar Debnath, Power Plant Instrumentation and Control Handbook: A Guide to Thermal Power Plants (2019, Academic Press).

- Steam: Its Generation and Use, The Babcock & Wilcox Company.

- P K NAG, Power Plant Engineering (2014, McGraw Hill India).

- Heselton, K. E., Boiler Operator’s Handbook (2005, Fairmont Press & M. Dekker).

- Woodruff, E., Lammers, H., & Lammers, T., Steam Plant Operation (2004, McGraw-Hill Professional).

- https://www.sciencedirect.com

- https://econtrol.com

- Muzammal Liaqathttps://thepetrosolutions.com/author/muzammal123/

- Muzammal Liaqathttps://thepetrosolutions.com/author/muzammal123/

- Muzammal Liaqathttps://thepetrosolutions.com/author/muzammal123/

- Muzammal Liaqathttps://thepetrosolutions.com/author/muzammal123/