Control valves are vital components of process industries, quietly ensuring that everything from oil refineries to chemical plants runs smoothly. These regulate flow, pressure, and temperature, ensuring operations stay safe and efficient. In this blog, we’ll explore down what control valves are, their essential parts, the different types, and how they function to keep processes on track.

What Are Control Valves?

Control valves are mechanical devices that manage the flow of fluids—liquids, gases, or steam in industrial piping systems. Unlike simple on-off valves, control valves can precisely adjust flow, pressure, or temperature by partially opening or closing, responding to signals from a controller. These ensure, every element works in desired range to maintain safe and efficient operations.

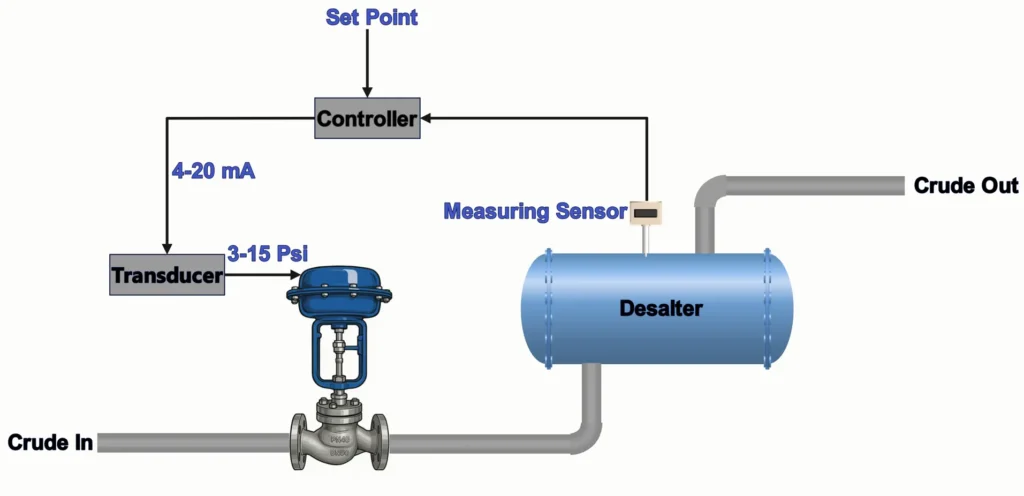

In industries like oil and gas, petrochemicals, or food processing, control valves are part of a control loop, working alongside sensors and controllers to maintain desired process conditions. For example, they might adjust the flow of crude oil in a refinery to prevent overpressure of desalter or regulate liquid flow in a chemical plant to ensure product quality. Their precision and versatility make them essential for process safety and operational efficiency.

How Control Valves Work

Control valves operate by adjusting the size of a flow passage based on a control signal, typically a 4 to 20 mA electrical current or 3 to 15 psi pneumatic pressure. Here’s how it works:

- Sensing: A sensor monitors process conditions like flow rate, pressure, or temperature and sends data to a controller.

- Processing: The controller compares the sensor’s data to a setpoint and sends a signal to the valve’s actuator.

- Adjusting: The actuator moves the valve’s regulating element (e.g., plug, disk, or ball) to adjust flow, aligning the process with the setpoint.

- Feedback: The sensor continuously monitors the process, ensuring precise control, often using feedback control.

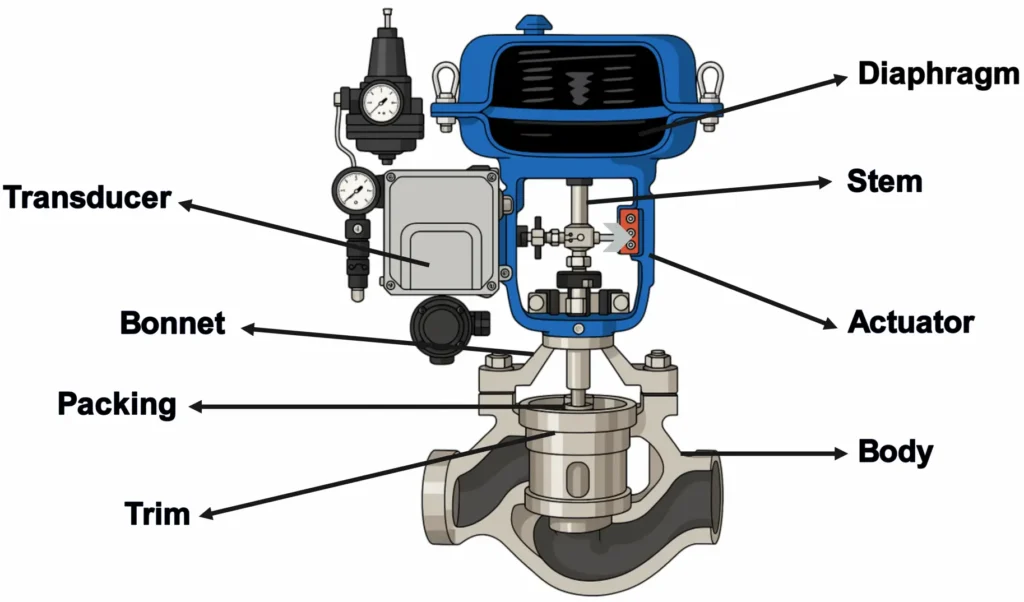

Key Parts of a Control Valve

A control valve system is a group of components working together to achieve precise control. Here are the main parts:

- Valve Body: The main structure that houses internal components and connects to the pipeline. It’s designed to withstand the fluid’s pressure, temperature, and corrosiveness.

- Trim: The internal parts, like the plug, disk, or ball, that directly control flow. The trim’s design determines how the valve regulates flow.

- Actuator: The power source that moves the valve’s regulating element. Actuators can be pneumatic (air-powered), electric, hydraulic, or manual.

- Bonnet: A cover that seals the valve body and supports the actuator, housing the packing to prevent leaks.

- Packing: Seals around the valve stem to prevent fluid leakage. Common materials include PTFE for lower temperatures and graphite for high temperatures.

- Signal Converter (Transducer): Converts control signals into a form, the actuator can use, like pneumatic pressure via an I/P converter.

Types of Control Valves

Control valves come in various designs, each tailored to specific applications. Following are the main types:

Sliding-Stem Control Valves

These valves use a linear motion to regulate flow, offering precision and versatility.

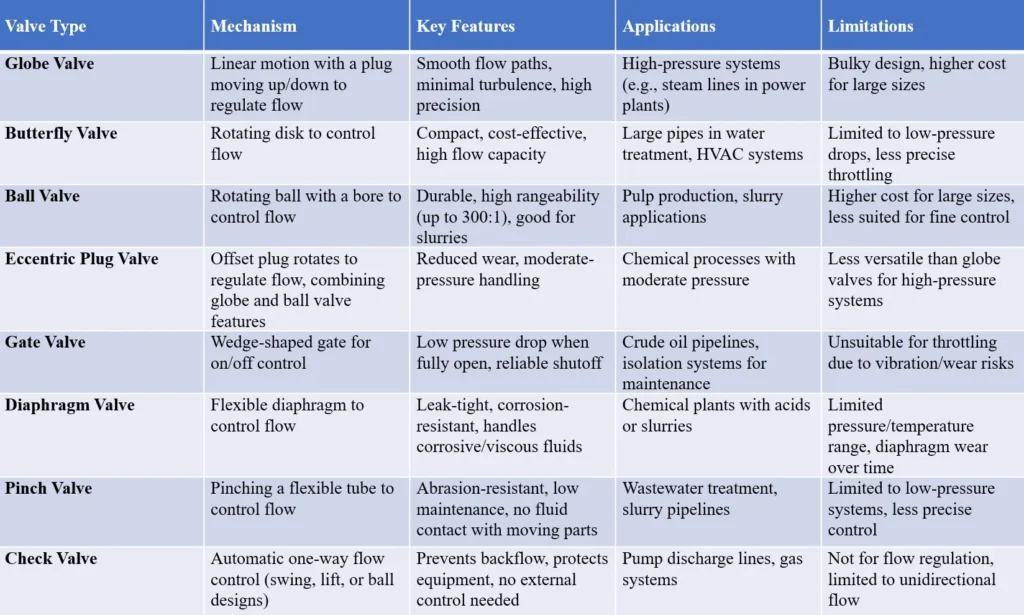

- Globe Valves: The workhorses of control valves, featuring a plug that moves up and down to control flow. Their smooth flow paths minimize turbulence, making them ideal for high-pressure systems like steam lines in power plants. They’re versatile but can be bulky.

- Double-Ported Globe Valves: These have two flow paths, balancing pressure to reduce actuator force. They’re suited for high-viscosity fluids in refineries.

- Three-Way Valves: Used for mixing or diverting flows, with three ports for applications like temperature control in heat exchangers.

Rotary-Shaft Control Valves

These valves use a rotating element, offering compact designs and high flow capacity.

- Butterfly Valves: Feature a rotating disk, perfect for large pipes in water treatment or HVAC systems. They’re cost-effective but limited to low-pressure drops.

- Ball Valves: Use a rotating ball with a bore to control flow. They’re durable, offer high rangeability (up to 300:1), and excel in slurry applications like pulp production.

- Eccentric Plug Valves: Combine features of globe and ball valves, with an offset plug that reduces wear. They’re ideal for moderate-pressure chemical processes.

Other Types of Valves

These valves offer specialized flow control for specific fluid types or applications.

- Gate Valves: Gate valves are designed for on/off control, using a wedge-shaped gate to open or close the flow path. They offer low pressure drop when fully open but are unsuitable for throttling due to potential vibration and wear. Widely used in crude oil pipelines and isolation systems, they ensure reliable shutoff during maintenance.

- Diaphragm Valves: Diaphragm valves use a flexible diaphragm to control flow, excelling in handling corrosive or viscous fluids. Their leak-tight design and corrosion resistance make them perfect for chemical plants dealing with acids or slurries, preventing leaks of hazardous substances.

- Pinch Valves: Pinch valves control flow by pinching a flexible tube, ideal for slurries and abrasive materials. Their simple design, with no moving parts in contact with the fluid, ensures abrasion resistance and low maintenance. They are common in wastewater treatment and slurry pipelines.

- Check Valves: Check valves prevent backflow by allowing flow in one direction only, operating automatically without external control. Available in swing, lift, or ball designs, they protect equipment in pump discharge lines and gas systems, preventing process upsets, such as in acid gas systems.

Comparison of Different Types of Control Valves

Control Valve Sizing and Selection

Choosing the right control valve is critical for efficiency and safety. The process involves:

- Analyzing Process Conditions: Consider flow rate, pressure, temperature, and fluid properties (e.g., corrosive or viscous).

- Calculating Flow Coefficient (Cv): Determines the valve’s capacity to handle the required flow at a given pressure drop.

- Selecting Valve Type: Match the valve to the process needs, considering factors like pressure drop, rangeability, and fluid type, such as those in hydrocracking units.

Incorrect sizing can lead to cavitation, excessive wear, or poor control, posing risks in high-stakes environments like petroleum refineries.

Why Control Valves Matter in Process Safety

Control valves are critical for process safety, preventing overpressure, ensuring stable operations, and enabling emergency shutdowns. For example, in a chemical plant, a globe valve can regulate steam flow to prevent equipment damage, while a check valve in an oil and gas system prevents hazardous backflow. Proper valve selection and maintenance align with OSHA compliance and risk management, reducing the likelihood of incidents.

People Also Asked Questions with Answers

What’s the difference between a control valve and a regular valve?

Control valves modulate flow, pressure, or temperature based on a control signal, offering precise adjustments within a control loop. Regular valves, like gate or check valves, are typically for on/off or isolation purposes.

Which control valve is best for high-pressure applications?

Globe valves excel in high-pressure applications due to their robust design and ability to handle significant pressure drops, making them ideal for steam or gas systems.

How do you fix a leaking control valve?

Tighten bolts, replace gaskets, or repack the stuffing box. For stem leaks under pressure, dismantling and repairing is the safest solution, though back-seating may work temporarily.

What is rangeability in control valves?

Rangeability is the ratio of maximum to minimum controllable flow rate. For example, a ball valve with 300:1 rangeability can handle a wide range of flow rates, ideal for varying process conditions.

What is positioner in a control valve?

A positioner in a control valve is an accessory that ensures the valve moves to the correct position as directed by a control signal from the system. It acts like a translator between the controller and the valve.

References:

- Howell Training Company, Valves: Construction, Operation, Troubleshooting, Service, American Petroleum Institute, 1971.

- Fisher Controls International, Control Valve Handbook, Fourth Edition, 2005.

- Skousen, P. L. Valve Handbook. McGraw-Hill, 2004.

- Johnson, Curtis D. Process Control Instrumentation Technology, Eighth Edition. Pearson Prentice Hall, 2006.

- Control Valve Handbook. 5th Edition. Emerson Process Management.

- https://www.valvemagazine.com

- https://control.com