Understanding Risk in Industrial Safety: Process, Tolerable, and Residual Risks

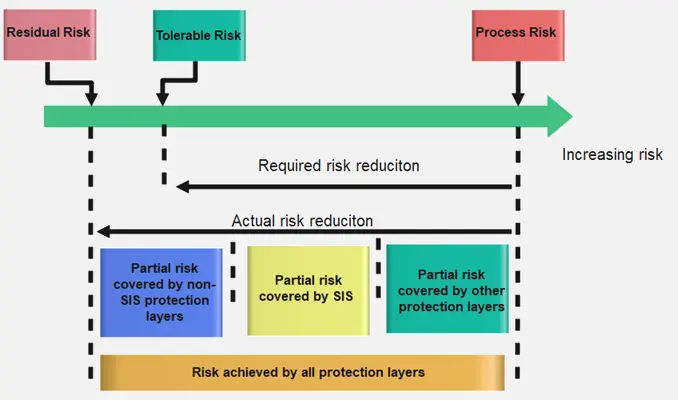

Risk is a measure of the frequency and consequence of a specified hazardous event occurring and plays a pivotal role in the industrial sector. Evaluating risk involves analyzing various scenarios, including process risk, tolerable risk, and residual risk. Let’s investigate into these concepts to understand their significance and applications in industrial safety management.

1. Process Risk

Process risk refers to the inherent risk associated with specified hazardous events in an industrial process. This includes the basic process control system (BPCS) and related human factors but excludes any designated safety protective features. In essence, process risk represents the baseline level of risk before the implementation of additional safety measures.

Key components of process risk include:

- Hazardous events: Scenarios where safety might be compromised.

- Human factor issues: Potential for human error impacting process safety.

- BPCS: The primary control systems designed for process management but not necessarily for safety protection.

2. Tolerable Risk

Tolerable risk is the level of risk that is deemed acceptable in a given context, taking into account societal and political values. It serves as a process safety target level, guiding industries to align with societal expectations and regulatory standards.

Factors influencing tolerable risk include:

- Societal values: Public perception and expectations of safety.

- Political considerations: Government policies and legal frameworks.

- Standards and regulations: National and international benchmarks for safety.

- Corporate policies: Organizational commitments to safety.

- Stakeholder input: Contributions from the community, local authorities, and insurance providers.

A clear definition of tolerable risk is essential for successful industrial risk management. This target level is often established through collaboration among stakeholders and adherence to established engineering practices.

3. Residual Risk

Residual risk represents the risk that remains after implementing safety protection layers. These layers may include engineering controls, administrative measures, and safety instrumented systems designed to reduce the likelihood or impact of hazardous events.

The concept of residual risk emphasizes:

- The importance of additional safety measures beyond the basic process.

- The necessity to evaluate whether the residual risk aligns with the defined tolerable risk levels.

Achieving Necessary Risk Reduction

The gap between process risk and tolerable risk defines the necessary risk reduction. This reduction can be achieved using various techniques, including:

- Engineering controls: Automated systems and barriers to prevent or mitigate incidents.

- Administrative measures: Training, procedures, and policies to minimize human error.

- Safety instrumented systems (SIS): Specialized systems designed to respond to hazardous conditions.

By identifying and implementing the appropriate combination of techniques, industries can ensure compliance with tolerable risk standards and enhance overall safety.

Certified Functional Safety Professional (FSP, TÜV SÜD), Certified HAZOP & PHA Leader, LOPA Practitioner, and Specialist in SIL Verification & Functional Safety Lifecycle, with 18 years of professional experience in Plant Operations and Process Safety across Petroleum Refining and Fertilizer Complexes.

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain