Distillation is the backbone of many industrial processes, from refining crude oil to producing high-purity chemicals. When it comes to distillation in engineering, selecting the right equipment can make or break your process efficiency, cost-effectiveness, and operational reliability. Two of the most common setups in the industry are tray columns and packed columns. Both have their strengths and weaknesses, and choosing between them depends on a variety of factors specific to your process. This guide will walk you through the key differences, advantages, and selection factors for tray and packed columns in a clear, engaging way. Let’s explore how to make the best choice for your process.

What is Tray Column Distillation?

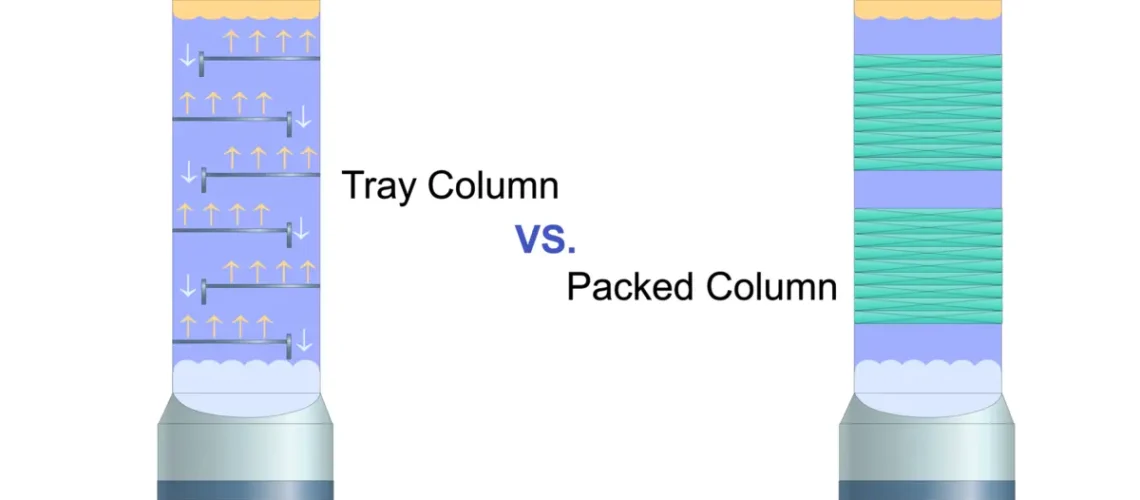

Tray columns, often called plate columns, are vertical towers equipped with a series of horizontal trays or plates that create distinct stages for vapor-liquid interaction. Each tray facilitates contact between the rising vapor and the descending liquid, allowing the more volatile components to enrich the vapor phase while less volatile components remain in the liquid. The process relies on a countercurrent flow, where liquid flows down through downcomers, and vapor rises through perforations, slots, or valves in the trays.

How Tray Columns Work

- Vapor-Liquid Contact: Vapor passes through tray openings (like sieve holes, valves, or bubble caps), bubbling through the liquid to promote mass transfer.

- Stage-wise Separation: Each tray acts as an equilibrium stage, enabling step-by-step separation of components based on their boiling points.

- Key Components: Trays, downcomers, weirs, reboilers (to generate vapor), and condensers (to produce reflux) work together to ensure efficient separation.

Types of Trays

- Sieve Trays: Simple perforated plates, cost-effective and suitable for high-capacity systems.

- Valve Trays: Feature adjustable valves for better control of vapor flow, ideal for variable operating conditions.

- Bubble-Cap Trays: Use caps to trap liquid, effective for low liquid flow rates but more expensive.

- Dual-Flow Trays: Perforated trays without downcomers, designed for high-capacity or fouling-prone systems.

What is Packed Column Distillation?

Packed columns replace trays with packing materials—random (e.g., Raschig rings, Pall rings) or structured (e.g., corrugated sheets)—to provide a large surface area for continuous vapor-liquid contact. Liquid flows downward over the packing, forming a thin film, while vapor rises through the voids, promoting mass transfer without discrete stages.

How Packed Columns Work

- Continuous Contact: Liquid spreads over the packing, interacting with rising vapor across the entire height of the packed bed.

- Mass Transfer Efficiency: The packing’s surface area enhances diffusion, with efficiency measured by the Height Equivalent to a Theoretical Plate (HETP) or Number of Transfer Units (NTU).

- Key Components: Packing materials, distributors (for even liquid flow), supports, hold-down plates, reboilers, and condensers.

Types of Packing

- Random Packing: Small pieces like Pall rings or Berl saddles, offering high surface area and capacity.

- Structured Packing: Ordered sheets for enhanced efficiency, though less suitable for high-pressure systems.

- Grid Packing: Used for high-capacity or fouling-prone services.

Tray Column vs Packed Column: Key Factors for Selection

Choosing between tray and packed columns requires balancing process needs, operational constraints, and economic considerations. Here’s a detailed comparison to guide your decision.

1. Process Requirements

- Tray Columns: Excel in high-throughput, multicomponent systems like crude oil fractionation or benzene-toluene separation. They handle complex mixtures and variable feed compositions effectively due to their staged design.

- Packed Columns: Ideal for processes requiring low pressure drops, such as vacuum distillation or separating heat-sensitive materials. They’re also suited for smaller-scale operations or systems with close boiling points.

2. Column Size and Height

- Tray Columns: Suitable for large-diameter columns (0.3–10 m) and heights (3–75 m). Larger diameters enhance tray efficiency by providing longer liquid flow paths.

- Packed Columns: More effective for smaller diameters (<0.6 m). In larger columns, liquid maldistribution can reduce efficiency, often requiring a 40% increase in packing height to compensate.

3. Pressure Drop

- Tray Columns: Experience higher pressure drops due to tray resistance (bubble-cap > valve > sieve). This can increase energy costs, especially in vacuum systems.

- Packed Columns: Offer lower pressure drops (e.g., 15–80 mm H₂O/m for random packings), making them ideal for vacuum or low-pressure operations.

4. Cost and Construction

- Tray Columns: More expensive due to complex tray fabrication, especially for bubble-cap trays (2–3 times costlier than sieve trays). Sieve and valve trays are more affordable but still pricier than packing.

- Packed Columns: Generally cheaper for small columns due to simpler packing materials. However, high-performance distributors and structured packings can increase costs.

5. Maintenance and Fouling

- Tray Columns: Easier to clean and inspect, particularly sieve or dual-flow trays, making them suitable for fouling-prone or corrosive systems.

- Packed Columns: Fouling can clog packing, reducing efficiency. Random packings like Pall rings handle fouling better than structured packings, but cleaning remains challenging.

6. Efficiency and Performance

- Tray Columns: Efficiency is measured by Murphree plate efficiency (30–100%), with empirical correlations. They’re reliable for high-throughput systems.

- Packed Columns: Efficiency is measured by HETP (0.46–0.9 m for random packings) or NTU/HTU. Structured packings offer higher efficiency but are sensitive to liquid maldistribution.

7. Operational Flexibility (Turndown)

- Tray Columns: Valve trays provide excellent turndown (4–5:1), handling variable flow rates well. Bubble-cap trays are ideal for very low liquid rates (<2 gpm/ft of weir).

- Packed Columns: Limited turndown due to minimum wetting requirements (>3 gpm/ft² for Pall rings), risking maldistribution at low flows.

8. Column Verticality

- Tray Columns: Less sensitive to column slant, as trays maintain horizontal liquid flow, though poor leveling can cause uneven distribution.

- Packed Columns: Highly sensitive to slant (e.g., 0.2–0.5° can reduce efficiency by 5–50% per degree), requiring precise installation.

Table: Tray vs Packed Column Comparison

When to Choose Tray Columns

Tray columns are the preferred choice in these scenarios:

- Large-Scale Operations: Ideal for high-throughput processes like crude oil refining or depropanizers, handling liquid loads up to 27.7 gpm/ft².

- Complex Mixtures: Effective for multicomponent separations, such as crude styrene purification, due to their staged design.

- Fouling-Prone Systems: Sieve or dual-flow trays are easier to clean, making them suitable for processes with solids or fouling tendencies.

- Variable Operating Conditions: Valve trays offer flexibility for fluctuating feed compositions or flow rates.

When to Choose Packed Columns

Packed columns shine in these situations:

- Vacuum Distillation: Low pressure drop makes them ideal for separating heat-sensitive materials, like aniline from nitrobenzene.

- Small-Scale Operations: Cost-effective for columns under 0.6 m in diameter, common in pilot plants or distilleries.

- Low Liquid Rates: Perform well at low reflux ratios, avoiding issues like weeping seen in tray columns.

- High-Efficiency Needs: Structured packings provide superior separation for precise applications.

People Also Asked Questions with Answers

Which is better for vacuum distillation?

Packed columns are preferred due to their lower pressure drop (15–80 mm H₂O/m), making them ideal for vacuum systems where minimizing energy costs is critical. Tray columns require larger tray spacing (24–30 inches) to manage entrainment in vacuum conditions.

How does fouling affect tray and packed columns?

Tray columns, especially sieve or dual-flow trays, handle fouling well due to easier cleaning and larger openings (≥1/2 in). Packed columns, particularly with small random packings, are prone to clogging

Can tray and packed columns be used for the same process?

Yes, but the choice depends on process conditions. For example, a high-throughput process favors tray columns, while vacuum distillation suits packed columns. Hybrid designs combining trays and packing are sometimes used for specialized applications.

When should I use a packed column over a tray column?

Choose packed columns for vacuum distillation, small-diameter columns, or low liquid flow rates. They’re cost-effective and have lower pressure drops.

Can packed columns handle variable flow rates?

Packed columns have limited turndown due to minimum wetting requirements (>3 gpm/ft²). Valve trays in tray columns offer better flexibility (4-5:1 turndown).

References:

- Harker, J. H., Richardson, J. F., & Backhurst, J. R. (2002). Chemical Engineering Volume 2. Butterworth-Heinemann.

- Kister, H. Z. (1992). Distillation Design. McGraw-Hill Professional.

- Dutta, B. K. Principle of Mass Transfer & Separation Process.

- Sinnott, R. K. Chemical Engineering Design Principles, Practice and Economics of Plant and Process Design. Elsevier/Butterworth-Heinemann.

- Treybal, R. E. (1980). Mass-Transfer Operations, 3rd ed., McGraw-Hill Book Company.

- https://epcmholdings.com

- https://www.machengineering.com