A windsock is a narrow, conical, or tapered cloth tube, open at both ends and looks like a giant sock. Its larger end is a fixed ring pivoted to swing freely, mounted on a pole at an elevated position. The tapper effect allows the wind sock to float in the air due to the inside pressure of the wind. A windsock is a basic indicator of wind direction and speed. They are typically used at airports to help pilots and in the chemical process industries where there is a risk of poisonous gas leakage. It can also be used for decorative purposes.

In 100 A.D Roman people used this windsock as banners to represent their army, while the Chinese & Japanese used this windsock for decorative purposes on special events.

Working of Windsock

The wind is blown into the wider side of the sock tube and then moves toward the narrower end, pointing the windsock in the same direction in which the wind is blowing. As the air flows, the windsock flies horizontally, its position helps to determine the strength or speed of the air. When the narrower end of the wind sock points to the north, it indicates that the wind is coming from the south, and vice versa.

Applications of Windsocks

Industrial Windsocks

Industrial windsocks are applied in chemical process industries to provide a visual indication of wind direction and speed, helping workers to evacuate the area and to avoid exposure to released toxic gases. The windsock is placed at a high point, in clear air so that it is clearly visible to all workers. It directs the workers to move to an assembly point, upwind of the released toxic gas. At least one windsock is essential as part of an emergency response plan for the plant’s potential emergency incidents.

Aviation Windsocks

Aviation or Airport windsocks are also used for the determination of wind speed with direction notations at airports. The windsock helps the pilots with flight operations for safe take-off and landing at the runway. The socks material which is used for airports is vinyl fabric which makes them highly durable with extreme strength. Aviation windsocks can be lighted internally or at the top for a night view.

Decorative Windsocks

It can be used for events or occasions or celebrations previously used by Japan, and China.

Determination of Wind Speed with Speed Charts

Each windsock contains some stripes over the sock material at a specific distance with equally different alternate colors. Windsock stripes also known as the term Knots can be used to determine the windspeed from 3 to 15 knots (5.5~28 km/hr) as shown below;

Parts of Windsock

A windsock is mainly comprised of a pole & sock. The sock is mounted on the pole part of the windsock so that it is free to rotate and changed its direction according to air. A windsock is made of a fabric of cotton, a synthetic (Nylon, polyester, etc) material, or a blend of the two.

The color of the windsock fabric may be red, white, yellow, orange, green, or a combination of these. The orange and white striped windsock is the most common color for windsocks. In general, the colors are selected in such a way that the windsock is clearly visible from various locations of the site.

The windsock pivoted or revolving system holds the windsock away from the pole so that it does not get damaged. This setup allows the windsock to easily get swollen with air and freely rotate around 360°. The Pivoted Arm and Pivoted Frame are two main windsock swivel systems in use for easy installation and movement of the sock.

Types of Windsocks

Windsocks can be classified based on their applications and manufacturing styles. According to use, a windsock can be of industrial, aviation, and decorative types as explained above. Further, depending on the manufacturing design, a windsock can be the Pivoted or Swivel Arm & Pivoted or Swivel Frame.

Swivel or Pivoted Arm Windsock

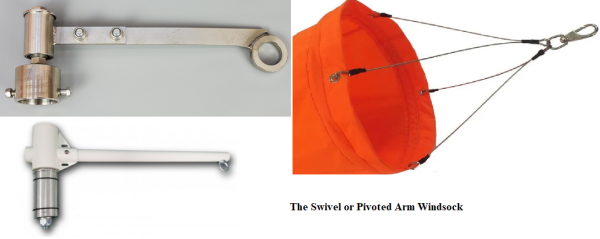

A Pivoted Arm type windsock comprises a bearing housing with an arm attached to it. The arm extends out and at its end is an eye or ring provided for the attachment of a swivel shackle or snap clip that is supplied and fitted to the end of the windsock harness. For this type of swivel system, a windsock is fitted with a harness. At one end the harness is attached to the windsock mouth ring and at the other end with a swivel shackle or snap clip which in turn attaches to the pivoted arm.

The Swivel Arm type can also be with a simple bearing attached to a hook as shown below

Swivel or Pivoted Frame Type Windsock

This type of windsock comprises a bearing housing with the frame to support the windsock attached to it. The frame consists of a large ring joined to a smaller ring with a distance between them of typically a quarter of the windsock length. An alternative to a full windsock frame is a single ring system that holds only the mouth of the windsock open.

For this type of swivel system, a windsock is fitted with a single band of eyelets or small slots. The larger mouth of the windsock is pulled over the frame and tied with cable ties or lacing cord which holds the windsock open and secures it from falling.

Standards for Windsock

The below windsock standards guide the windsock specifications, installation procedures, and speed assessments from windsocks.

1. Federal Aviation Administration, USA

According to the FAA Specifications for Wind Conse Assemblies, a properly functioning windsock orients itself to a wind of at least 3 knots (5.6 km/h; 3.5 mph) and fully extends in the wind of 15 knots (28 km/h; 17 mph). This standard also tells about the fabric, size, type, and style of win cone assembly.

2. Transport Canada

According to the Aeronautical Information Manual of Transport Canada, a 15 knots (28 km/h) wind fully extends the windsock; a 10 knots (19 km/h) wind raises it to 5° below the horizontal, and a 6 knots (11 km/h) wind raises it to 30° below the horizontal.

3. ICAO

ICAO (International Civil Aviation Organization) standards specify a cone-shaped windsock at least 3.6 m long and 0.9 m in diameter at the large end. It should be visible from an altitude of 300 m and ideally be of a single color. If it is necessary to use two colors, they should ideally be orange and white arranged in five alternating bands, with the first and last darker in tone.

References

Top references and for further study;

- Windsock Working and Importance by www.chemicalengineeringworld.com.

- Windsock Blogs at www.windsockcompany.co.uk

- Interesting facts about industrial windsocks

- A Windsock Swivel Systems

- www.wikipedia.com

For further information, discussion and queries please comment in the box below or contact us at admin@ or follow us on Facebook & LinkedIn.