Ultrasonic flow meters are revolutionizing flow measurement devices that use sound waves to measure flow rates precisely with their non-invasive, accurate, and versatile designs. Whether you need transit-time meters for clean liquids, Doppler meters for slurries, or cross-correlation meters for complex flows, there is a solution for every process industry need. By understanding their principles, types, and limitations, you can choose the right meter for your application, ensuring safety and efficiency.

What Are Ultrasonic Flow Meters?

Ultrasonic flow meters are innovative tools that measure the flow rate of liquids or gases in a pipe using high-frequency sound waves. Unlike traditional meters that rely on mechanical parts, many ultrasonic models are non-intrusive, meaning they can clamp onto a pipe’s exterior without touching the fluid. This makes them ideal for applications where hygiene, minimal maintenance, or system integrity is crucial. From monitoring clean water to handling slurries, these meters are versatile and widely used in industries like petroleum refining, chemical plants, and environmental engineering.

Why They Matter:

- Non-Invasive: No need to cut pipes, reducing risks of leaks or contamination.

- Versatile: Suitable for clean liquids, gases, and even particle-laden fluids.

- Accurate: Achieve accuracies from ±0.15% to 5%, depending on the design.

- Low Maintenance: No moving parts mean less wear and tear.

How Do Ultrasonic Flow Meters Work?

Ultrasonic flow meters use sound waves to measure fluid velocity. Transducers, sensors that send and receive ultrasonic signals, emit waves into the fluid, and the way these waves interact with the flow reveals the velocity. This velocity, combined with the pipe’s cross-sectional area, gives the volumetric flow rate. The three main types of ultrasonic flow meters are transit-time, Doppler, and cross-correlation.

1. Transit-Time Flow Meters

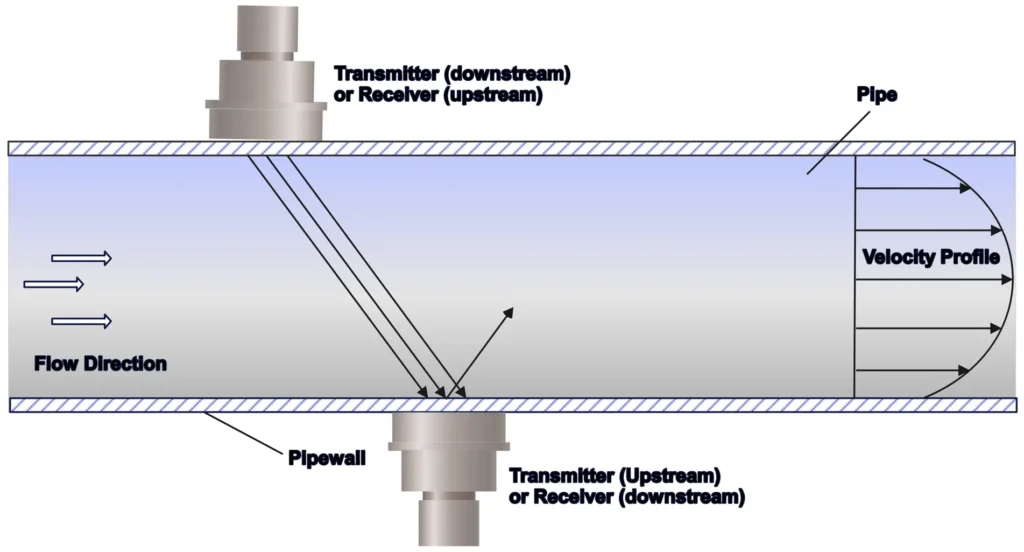

Transit-time flow meters work by measuring the time it takes for ultrasonic pulses to travel with and against the fluid’s flow.

How They Work:

- Two transducers are placed diagonally across the pipe, one upstream and one downstream.

- Each transducer sends ultrasonic pulses to the other. The pulse traveling with the flow (downstream) arrives faster, while the upstream pulse takes longer.

- The time difference (Δt) between these pulses is proportional to the fluid’s velocity, calculated using formulas.

Key Features:

- Accuracy: ±0.15% to 2% for clean fluids, with multi-path designs reaching higher precision.

- Velocity Range:1 to 100 ft/s (0.03 to 30 m/s).

- Applications: Ideal for clean liquids like water or oil, and gases in pipelines.

- Configurations: Available as spool-piece (built into the pipe) or clamp-on (external) designs.

Challenges: They require clean fluids with minimal solids or bubbles, as these can disrupt the signal. Proper installation, with 10-20 pipe diameters of straight pipe upstream, is critical for accuracy.

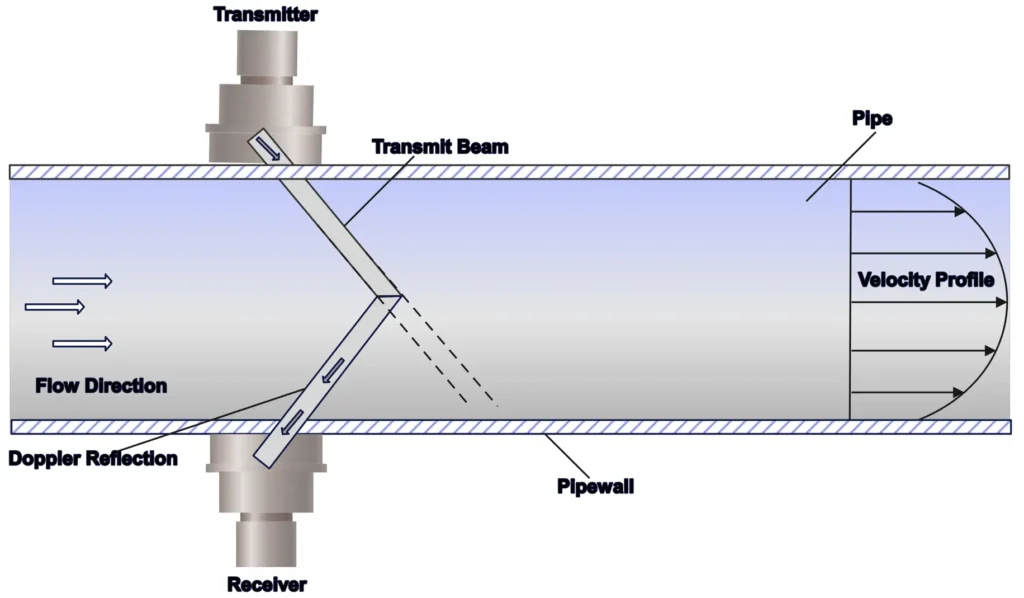

2. Doppler Flow Meters

Ever noticed how a siren’s pitch changes as an ambulance passes by? That’s the Doppler effect, and Doppler flow meters use this principle to measure flow.

How They Work:

- A transducer sends a continuous ultrasonic beam (typically 0.5 MHz) into the fluid.

- Particles or bubbles in the fluid reflect the waves back to a receiver with a frequency shift (Δf) proportional to the fluid’s velocity.

Key Features:

- Accuracy: ±2% to 5% of full scale.

- Velocity Range:2 to 60 ft/s (0.06 to 18 m/s).

- Applications: Perfect for fluids with solids or bubbles, like slurries or wastewater.

- Configurations: Typically clamp-on, with single or dual transducers.

Challenges: They need particles or bubbles to reflect waves, so they don’t work with clear liquids. Accuracy depends on particle distribution, and heavy slurries can cause reflections near the pipe wall, skewing results.

What is the difference between transit-time and Doppler flow meters?

Transit-time meters measure the time difference of ultrasonic pulses traveling with and against the flow, ideal for clean fluids with ±0.15-2% accuracy. Doppler meters measure frequency shifts from waves reflecting off particles, suitable for dirty fluids but less accurate (±2-5%).

3. Cross-Correlation Flow Meters

Less common but powerful for complex flows, cross-correlation flow meters measure the time it takes for flow disturbances to travel between two points.

How They Work:

- Two ultrasonic beams are placed a known distance apart along the pipe.

- The signals from these beams are compared to find a matching pattern, indicating the time it takes for a disturbance (like turbulence or bubbles) to move between them.

- Then the velocity is calculated:

Key Features:

- Accuracy: 2-3% uncertainty.

- Applications: Ideal for multiphase flows, like oil/gas mixtures or slurries.

- Configurations: Often clamp-on, requiring flow disturbances for operation.

Challenges: They need significant flow disturbances and complex electronics, making them less

common than other types.

How accurate are ultrasonic flow meters?

Transit-time meters achieve ±0.15-2% accuracy, while Doppler meters range from ±2-5%, and cross-correlation meters are around 2-3%. Calibration and installation are key.

Can ultrasonic flow meters measure gas flow?

Yes, transit-time meters can measure gas flow, especially with wetted transducers or advanced clamp-on designs using low frequencies (0.2-0.5 MHz). Accuracy depends on proper installation and gas properties.

Types of Ultrasonic Flow Meters

Ultrasonic flow meters are classified by their transducer mounting and measurement technique. Here’s a breakdown:

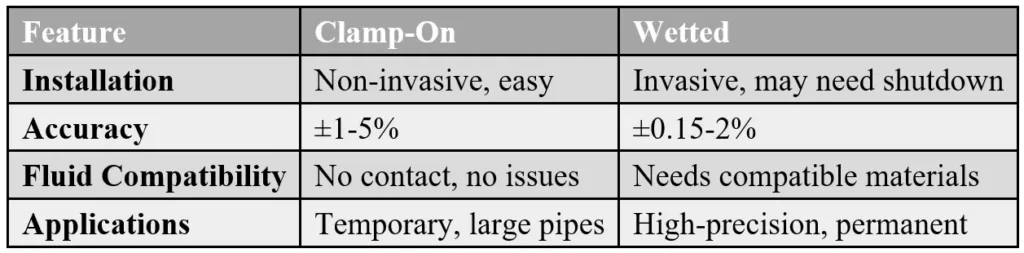

1. Clamp-On Transducers:

- Mounted externally on the pipe, non-invasive.

- Ideal for retrofitting or temporary measurements.

- Best for water treatment, HVAC, or large pipelines.

- Limitation: Lower accuracy (±1-5%) due to pipe wall interference; requires sonically conductive pipes (e.g., metal).

What are the limitations of clamp-on ultrasonic flow meters?

They face issues like impedance mismatch, refraction through pipe walls, and sensitivity to pipe tolerances, leading to higher uncertainties (up to 5%).

2. Wetted Transducers:

- Mounted inside the pipe or in a spool piece, contacting the fluid.

- Offer higher accuracy (±0.15-2%) and better signal-to-noise ratio.

- Common in oil and gas or chemical plants.

- Limitation: Requires pipe modification and fluid-compatible materials.

3. Multi-Path Designs:

- Use multiple ultrasonic paths (3, 5, or up to 18) to average velocity profiles.

- Enhance accuracy in turbulent flows, often used in custody transfer.

Performance and Operating Constraints

Ultrasonic flow meters are powerful but have specific requirements:

- Pipe Size: Suitable for pipes from 1/8 inch to large diameters, with no upper limit.

- Fluid Requirements:

- Transit-Time: Clean fluids, minimum velocity 0.1 ft/s.

- Doppler: Needs particles or bubbles, minimum velocity 0.5 ft/s.

- Flow Conditions: Require turbulent flow (Reynolds > 4000-10,000) for most designs, though pulse repetition handles laminar flow.

- Temperature and Pressure: Operate up to 400°C, with wetted designs limited by flange ratings.

Installation Tips:

- Ensure 10-30 pipe diameters upstream and 5-10 downstream of straight pipe to avoid flow distortions.

- Align transducers horizontally to prevent perspective gas or solids accumulation.

- Use accurate pipe and fluid data for calibration.

Maintenance Tips:

- Check clamp-on transducers for coupling material degradation.

- Wetted transducers may need flow interruption for replacement.

- Calibrate electronically or at manufacturer facilities for best accuracy.

Applications in Process Industries

Ultrasonic flow meters shine in various industries:

- Oil and Gas: Measuring crude oil, natural gas, or LNG flows.

- Chemical Plants: Monitoring corrosive or hazardous fluids.

- Water Management: Tracking water or wastewater in treatment plants.

- Power Generation: Measuring cooling water or steam flows.

- Environmental Engineering: Monitoring effluent or irrigation flows.

Advantages and Limitations

Advantages:

- Non-intrusive designs reduce leak risks and maintenance.

- No pressure drop, maintaining system efficiency.

- Wide velocity range and bidirectional measurement.

- Cost-effective compared to traditional meters like orifice or venturi.

Limitations:

- Transit-Time: Struggle with solids or bubbles; need straight pipe sections.

- Doppler: Require reflectors; less accurate; unsuitable for concrete or lined pipes.

- Cross-Correlation: Need flow disturbances; complex electronics.

- Clamp-On: Face coupling issues due to thermal expansion or pipe material.

References

- Bela G. Liptak (1993). Flow Measurement. CRC Press.

- Walt Boyes (2003). Instrumentation Reference Book. Butterworth-Heinemann.

- Adams, Mark Albright, C. H. Jr. Auer, Len Barrows, S. Beach, J. N. (1999). Process Industrial Instruments and Controls Handbook. McGraw Hill.

- Spitzer, D. W. (2004). Industrial Flow Measurement. ISA: The Instrumentation, Systems, and Automation Society.

- Baker, R. C. (2002b/2003). Flow Measurement Handbook.

- https://www.sciencedirect.com

- https://www.bakerhughes.com