How to Use a Risk Matrix to Determine SIL?

Safety Integrity Levels (SIL) are critical for ensuring that industrial processes meet acceptable safety standards. A risk matrix is one of the most widely used tools for determining target SIL levels, especially in process industries. It combines qualitative and quantitative methods to assess risks across categories like safety, environmental, and economic impacts. Risk matrices provide an intuitive way to estimate the severity and likelihood of risks, offering a structured approach to identify when Safety Instrumented Functions (SIFs) are required.

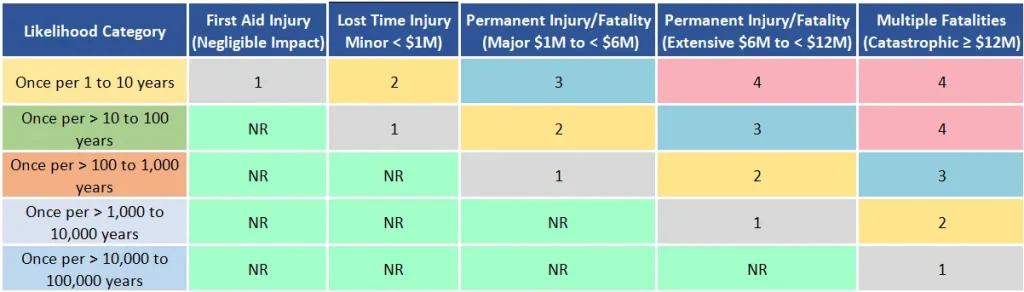

Risk Matrix categorizes consequences, either qualitatively or quantitatively, across various domains of harm, including safety, environmental, and economic risks. Typically, a risk matrix features four or more consequence categories, with assigned numbers indicating the required SIL to reduce risk to tolerable levels.

Some companies combine the SIL selection with the HAZOP reviews as they us the same risk martix for risk assessment during HAZOP. This approach is called the modified HAZOP review.

The example of risk matrix presented below incorporates three types of consequences, each categorized into four levels. This framework enables the estimation of target Safety Integrity Levels (SIL) for various risk types, including safety, environmental, and economic risks. Areas shaded in light green represent tolerable risks, where a Safety Instrumented Function (SIF) is not required (indicated as NR). In contrast, the numbers within the boxes specify the SIL level of the SIF needed to reduce the risk to an acceptable level.

Step-by-Step Guide to Using a Risk Matrix for SIL Determination

- Identify the Consequence: The first step in determining the SIL using a risk matrix like this is to assess the severity of the hazard and categorize its consequences on the matrix. This process should be carried out individually for each risk receptor. For example, personnel risk can be considered first.

- Estimate Likelihood of Occurrence: The next step is to estimate the frequency of the occurrence of this specific risk and assign it to the appropriate likelihood category on the risk matrix. For each hazard, estimate how frequently the event might occur. This can be done:

- Qualitatively, for simple systems.

- Quantitatively, for more detailed analysis.

The risk matrix uses this likelihood along with the severity to assign a SIL level.

- Combine Severity and Likelihood Use the intersection of the consequence and likelihood categories within the risk matrix to determine the target SIL. For example:

- A high-severity, low-frequency event might require a SIL 3 SIF.

- A low-severity, frequent event might require no SIF (denoted as “NR”).

- Repeat for All Risk Receptors: Evaluate safety, environmental, and economic risks independently. The highest SIL across these categories will dictate the final requirement for your SIF.

For instance, if the personnel risk involves a lost-time injury and the likelihood of occurrence is once in ten years, the risk matrix is indicating the need for a SIL 2 SIF to achieve a tolerable residual risk. This process would then be repeated to determine the required SIL for the environmental and economic risks of the scenario

Key Point in Determining the SIL:

The final SIL for the SIF would correspond to the highest SIL requirement across the different harm categories. This ensures that the risk is tolerable for all forms of harm identified in the assessment.

Practical Example: Fuel Oil Storage Tank Scenario

Imagine a heavy fuel oil storage tank is overfilled, leading to:

- Roof damage

- Oil spillage into the containment dike

Here’s how the risk is assessed:

- Safety Risk: Minimal, as the team believes the chance of ignition is negligible. No SIF is needed for safety.

- Environmental Risk: Requires soil remediation. With a spill likelihood of once in 10 years, the matrix indicates a SIL 3 SIF.

- Economic Risk: Roof repair costs over $1 million. The matrix assigns a SIL 2 SIF for this risk.

Final SIL: The highest SIL among the three categories is SIL 3, so a SIL 3 SIF is required.

Key Considerations for Accurate SIL Estimation

- Avoid Double-Counting Mitigation: Protective layers should not be counted twice in reducing both severity and likelihood.

- Use Detailed Analysis: For complex systems, complement the risk matrix with Layer of Protection Analysis (LOPA) for more precise results.

- Account for Independence: Ensure that all SIFs and protective measures are independent of each other to avoid cascading failures.

Why SIL Estimation Matters for Process Safety

Using a risk matrix simplifies the SIL determination process, making it accessible even for non-specialists. It bridges the gap between qualitative assessments and more advanced quantitative tools, enabling engineering professionals to ensure safety, environmental compliance, and cost control in industrial operations.

For engineering teams looking to enhance their process safety systems, incorporating a risk matrix into your workflow can be a game-changer. It not only ensures compliance but also builds resilience against operational hazards.