Reliability is a crucial aspect of any system, especially in industries where operational efficiency and safety are critical. Whether it’s an aircraft in flight, an unmanned space mission, or industrial machinery, reliability determines how consistently a system performs its intended function over a specified period.

In this blog, we’ll break down what reliability means, why it matters, and how it is measured.

What is Reliability?

Reliability, denoted as R(t)R(t)R(t), is defined as the probability that a system will function as intended, within its design limits, for a specific time interval. Unlike vague statements like “this system has a reliability of 0.95,” a meaningful reliability assessment must always include a time duration.

For example, saying “the reliability of this system is 0.98 for a mission time of 100 hours” makes sense because it clearly defines the operating time.

Key Aspects of Reliability

For a system to be considered reliable, five important factors must be evaluated:

- Intended Function – The primary purpose of the system must be clearly defined.

- Operational Requirement – The conditions under which the system is expected to function must be established.

- Performance Standard – What qualifies as satisfactory performance should be determined.

- Design Constraints – The system must function within its specified operating limits.

- Time Interval – Reliability is only meaningful when measured over a set period.

Why Time Matters in Reliability

Reliability is inherently time-dependent. A system may function perfectly for an hour but fail after prolonged use. That’s why reliability assessments always specify the mission time or operating duration.

Consider a 10-hour flight. The question engineers ask is:

“What is the probability that the aircraft will successfully operate for the entire 10-hour duration?” The answer would be the reliability for the 10 hours duration.

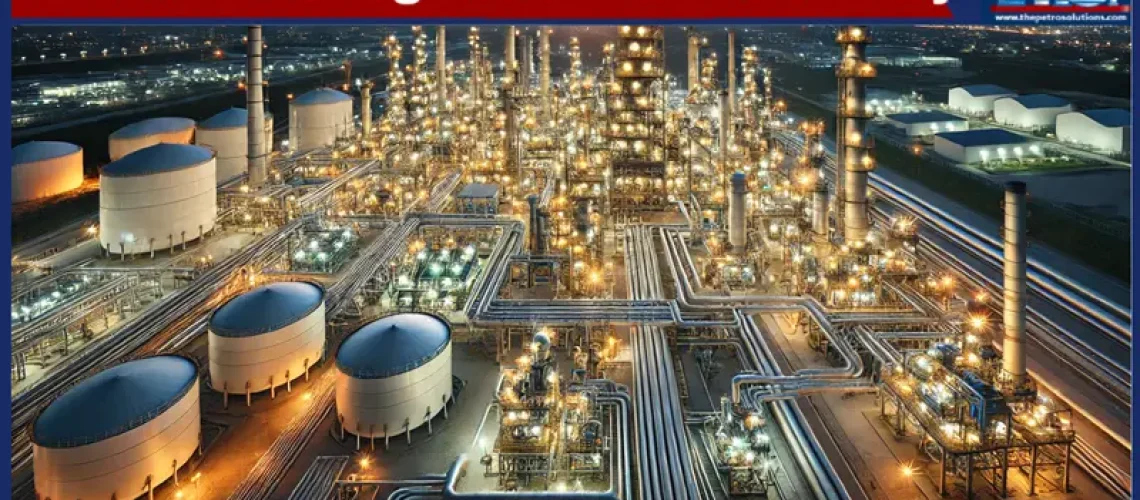

Real-World Applications

- Aerospace & Aviation – Aircraft and spacecraft operate under conditions where in-flight repairs are impossible, making reliability a critical factor.

- Manufacturing & Industrial Equipment – Factories rely on machines with high reliability to prevent downtime and losses.

- Medical Devices – Equipment like pacemakers must have extremely high reliability due to their life-critical function.

How is Reliability Measured?

When evaluating life test results, the reliability function is calculated by dividing the number of surviving units at any time by the total number of units starting the test.

R(t)=Ns / N

Where:

Ns = Number of surviving units at a given time

N = Total number of test units