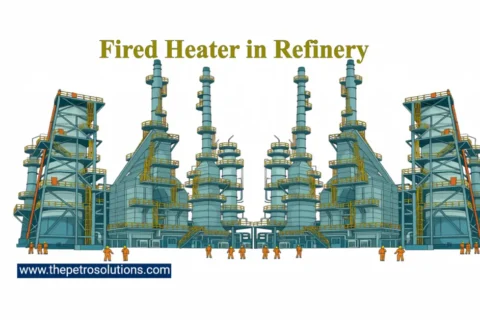

Oil refineries are major contributors to a country’s economy. The worldwide petroleum refining industry currently faces high impact challenges due to uncertainties about the crude oil feedstock, characteristics of petroleum products, and stringent environmental regulations. Improving process technologies, implementing technological advancements, increasing refinery complexity and versatility; integrating refining with petrochemical industries, increasing the efficiency of energy use, increasing operational efficiencies, maximizing productivity, producing refined products at lower costs, improving reliability, and avoiding shutdowns or breakdowns are keys to meeting these challenges.

Major Petroleum Oil Refinery Problems

The following are major challenges and solutions encountered by petroleum refining. But these can be converted into opportunities to upgrade the refining processes and find new ways to become more profitable.

1. Effects of Environmental Regulations on Oil Refining

The strict environmental regulations like IMO (International Maritime Organization) 2020 and Euro fuel specifications are the most impacting factor on the petroleum refining business. IMO 2020 has resulted in a dramatic reduction from 3.5% to 0.5% sulfur content of marine fuel. In the same way, euro regulations have resulted in cleaner and higher-quality transportation fuels like ULS (Ultra Low Sulfur) petroleum products (Diesel and Gasoline). Further, strict environmental regulations are also in place for pollution control in oil refineries. Air emissions and toxicity levels in effluents are major pollutants.

As further standards are tightened, it will become more and more challenging to economically produce finished products from crude oil supplies. To comply with these legislations, significant adjustments are required to the refining process, revamps, and installation of newly integrated process units that necessitate significant capital investments. Further, while revamping and installing new facilities, plan for at least 15 years.

2. Price Fluctuation of Crude Oil and Petroleum Products

The price of crude oil and refined petroleum products are important parameters to find the profit margin of the petroleum oil refinery. The uncertainty in crude oil and petroleum products prices has a significant impact on economic stability. Owing to external factors caused by geopolitical or some other situations we can not forecast the price of crude oil and petroleum hydrocarbon products prices which can badly affect the gross refining profit margins of an oil refinery. In the crude oil price chart below gasoline prices vary with the crude oil price, but sometimes gasoline price varies due to seasonal demands or specifications changes.

3. Impact of crude oil quality on the oil refining process

Currently, the quality of crude oil has been worsening and continues to deteriorate due to declining reserves of light crude. But on the other hand, the demand for high-quality products is continuously increasing. Further, the lighter, high-quality crude oils are costly, reducing the gross refinery margins.

Variation in characteristics of crude oil feedstock or Utilization of heavy, extra heavy, sour, synthetic, and opportunity crude oils, causes a number of processing challenges. Crude oil variability can result in product quality issues, unit reliability, increased corrosion and fouling, unexpected shutdown, and quality issues of emissions and effluents.

It is better to understand the quality of the crude oil, blend the crude in an operable range, and anticipate and adapt to the changing operating conditions and impacts. This requires constant fine-tuning of process plants and sometimes lead to inefficient and costly refining operation that ultimately impact profitability. Failing to do so can result in unexpected shutdowns, short-run lengths, increased system corrosion, fouling, catalyst poisoning, quality-related issues, and in the end production losses.

4. Change in Demand for Petroleum Products

The demands for transportation fuels like gasoline, diesel jet fuel, etc. have never been stable and are changing day by owing to many factors. Drop-in sales of any one of the products can halt the whole refining process. Refineries must be flexible with the new demands and must have sufficient storage to absorb such a sale decline. Further, try to produce and sell more valuable or high-priced products keeping in control quality parameters.

5. External Factors Affecting Oil Refining Process

Possible trade wars, nature, epidemics like COVID-19, geopolitical changes, wars, economic growth, and policies of the country continue to add complexities to the refineries. Demand for transportation fuels in the world has fallen because of the spread of coronavirus. In response, refineries have reduced their capacity utilization to meet the overall demand for petroleum products. Even, some refineries remained shut down during strict lockdown due to COVID-19 worldwide. Although, these are unforeseen incidents the refiners must find ways to survive in such unpredictable situations.

6. Unavailability of Skilled Workforce

The oil refining industry is facing rising shortages of skilled employees. Trained and experienced workers are critical to ensure reliable operation. But more experienced petroleum oil refinery employees retire, and there is no one skilled enough to replace them. Further, the movement of experienced employees and the unavailability of trained personnel is a big challenge to the processing industry.

To face the skills worker shortage challenge, the refiners must develop comprehensive in-house training programs and conduct on-the-job training of the workforce by shifting knowledge from seniors. Adopt, the latest training techniques like OTS (Operators Training Simulators) for training the workforce.

7. Impact of Renewable Energy on Oil Refineries

A global shift towards renewable energy resources from fossil fuels has contributed to lowering the demand for petroleum products, particularly gasoline. This shift in the future will have significant impacts on the refiners particularly in Europe. Oil refiners will see slower growth in the demand for gasoline and diesel due to electric vehicle adoption, increased biofuel blending, and other factors. But for aviation and shipping replacement of petroleum fuel will be challenging.

8. Technology Challenges to the Oil Refining

Each day there are new innovations in the field of the process industry and refiners have to go for process modification to adopt advancements such as new catalysts, improved processes, the latest instrumentation, etc. All petroleum oil refinery processes are continuously developing to get more and more from crude oil, with zero losses and minimum environmental damage. In the long run, it is better to analyze these changes and implement them for the process to sustain or improve the profit margins otherwise he might be out of the business.

9. Unplanned Downtime

Unplanned downtimes are expensive and costly interns of repairs and production losses, often due to equipment failures, power outages, maintenance issues, human errors, etc. that could have been avoided. The cost of a large-scale incident could run millions of dollars. The price of missed production for an average refinery has been estimated between 0.5~ $1.5 million per day.

In many cases, proactive maintenance could identify and resolve the problem before complications arise. In others, upgrading or replacement of the equipment could reduce the likelihood of breakdowns.

10. Bottom of the Barrel

The bottom of the barrel or residue has become a bottleneck for oil refineries because of the gradual decrease in the demand for fuel oils. An increase in the production of heavy and extra heavy crude oils has also increased the quantities of residue which restricts the petroleum oil refinery’s throughput. In this situation, bottom-of-the-barrel up-gradation has become attractive, economical, and in some cases absolutely imperative. In the bottom of the barrel upgrading, the cheap residue is converted to lighter more valuable transportation fuels or petrochemicals.

For further information, discussion and queries please comment in the box below or contact us at admin@ or follow us on Facebook & LinkedIn.

1 thought on “Major Challenges to the Oil Refineries”

My question is what type of the operational problems we will have to face to the diesel hydrotreating process?