HAZOP Study (Hazard and Operability Study) is a structured and systematic technique for identifying potential hazards and operability problems in a process system. It is widely used in industries like oil and gas, chemicals, and manufacturing to ensure the safety and efficiency of operations. A HAZOP study is undertaken by the application of formal, systematic, and critical examination of the process and engineering intentions of the process design. The potential for hazards or operability problems are thus assessed, and malfunction of individual items of equipment and associated consequences for the whole system are identified. This examination of the design is structured around a specific set of parameters and guidewords, which ensures complete coverage of all major possible problems.

Other blogs related to the HAZOP Study topics are;

- General Rules for HAZOP Study

- Hazop Study Terminologies

- Guidelines for Nodes Selection in HAZOP Study

- Responsibilities of a Good HAZOP Team Leader

- Stages of Hazard Study of Process Plants

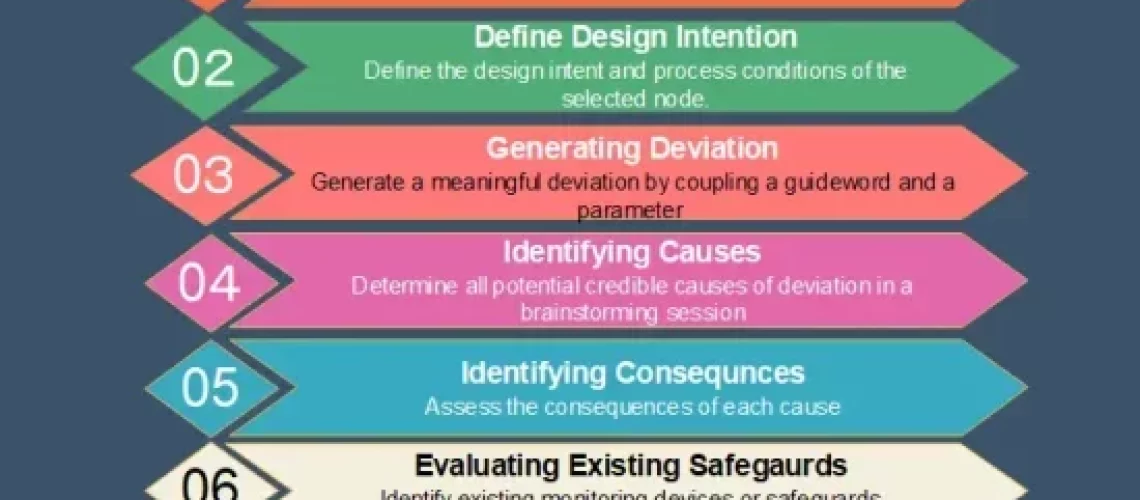

When the process design is almost final and engineering line diagrams are ready then a formal HAZOP review can be planned. The step-by-step procedure of HAZOP Study Methodology is discussed below;

1. Node Selection

Before the review actually starts, the Team Leader and Scribe should identify, highlight, and list the nodes that will be selected for the review. The Team Leader should confirm the selection with the Project Manager before the review begins. A facility or process is divided into systems and subsystems. The subsystems will usually contain one or two components that are the “nodes.” The guidelines for identifying and selecting nodes for safety reviews are as follows:

- Divide the facility into process systems and subsystems on the P&ID diagram.

- Follow the process flow of the system under study.

- Isolate subsystems into major components that achieve a single objective (e.g. distillation column, reactor, pumping unit, heat exchanger etc.

2. Design Intention

Engineer familiar with the section describes its purpose and operation to familiarize all HAZOP Team and form a basis for discussion. A full description should be developed, including all the key parameters, and the HAZOP report should include the design description. a design intention for the step is formulated and recorded. This should include a statement of the intended operational range (envelope) so that the team can recognize any situations lying outside this range as deviations.

A design intention may refer to equipment items in the section, to materials, conditions, sources, and destination, to changes or transfers, as well as to the means of control and timing of a step. It not only refers to plant equipment but covers what is intended to be done within the section being analyzed.

3. Generating Deviation

The next step is to generate a meaningful deviation by coupling a guideword and a parameter and apply to the selected node. A deviation can be generated by taking a parameter and combining it with each guideword in turn to see if a meaningful deviation results (the parameter-first approach). The alternative approach is to take a guideword and try each parameter in turn (the guideword-first approach) but parameter first approach is widely applied.

The term “guideword” is used here for an action word or phrase such as “no,” “more of,” and “as well as. The term “parameter” is used here as the generic name for a variable, component, or activity referred to in the stage under study—for example, flow, pressure, transfer, and measure. The purpose of the guidewords is to assist the team in a creative and thorough search for meaningful deviations, it is important to select a set that works well for the problem being studied.

4. Identifying Causes

Once a meaningful deviation has been identified, the team then finds a cause. It is important that causes are clearly described, as broadly similar causes may have distinctly different consequences. A brainstorming session should be performed to identify as many causes as possible, remembering that causes may be related to human factors as well as to hardware items. In seeking causes (and evaluating consequences), it is essential that all members of the team take a positive but not defensive, attitude. This is particularly important for any members related to design.

5. Identifying and Evaluating the Consequences

The approach applied while finding consequences is to ignore the already applied safeguards so that the ultimate effects are understood and the worst outcome has been identified. The consequences of each cause must be carefully analyzed to see whether they take the system outside the intended range of operation.

It is essential to fully identify all of the consequences, both immediate and delayed, and both inside and outside the section under analysis. It often helps to analyze how the consequences develop over a period of time, noting when alarms and trips operate and when and how the operators are alerted. This allows a realistic judgment on the likelihood and influence of operator intervention.

6. Evaluating Existing Safeguards

Identify existing monitoring devices and/or safeguards such as an alarm, trip, or pressure safety device, etc on the selected node. The is decided that if current safeguards are sufficient to control the ultimate consequence. If a safeguard of the specific consequence is not identified then actions to eliminate or mitigate the problems are recommended.

7. Risk Assessment

It can be very time-consuming to do a risk assessment for every problem. However, if the team has a familiar, well-constructed risk matrix which is appropriate to that particular industry, they will become efficient at assigning likelihood and severity categories.

The risk assessment is probably best made either after the team has clarified the consequences or following the discussion of the safeguards. The advantage of this approach is that it shows the worst-case consequences, the extent to which these are alleviated by existing safeguards, and then the effects of the proposed actions. A further benefit of risk assessment after the consideration of the consequences is that minor problems are apparent and further discussion can be terminated.

8. Recommendations

Decide if current safeguards are sufficient given the ultimate consequence ‐ if not identify any Actions to eliminate or mitigate the problems. Make recommendations to mitigate the consequences if the severity or probability is unacceptable, according to the company’s risk acceptance levels.

There must be consensus among the team on any positive action, as well as on the causes and consequences. Also, further causes, consequences, and deviations that might be associated with a change should be considered and covered within the HAZOP study. It is essential that all recommendations/ actions are unambiguous and clearly recorded so that they can be understood at a later stage in the project by non-team members.

9. Recording

The Scribe in Hazop make worksheet records and takes notes during the review. Sufficient detail must be recorded for the potential problem to be understood outside the meeting by persons who were not present.

The Scribe should transcribe all the “official” discussions or notations onto the worksheet as directed by the Team Leader. No other team member should direct the Scribe. When other team members are allowed to direct the Scribe, confusion and misdirection may result, in losing valuable time for review as well as resulting in incorrect information.

Top References

- Safety and Security Review for the Process Industries Dennis P.Nolan

- HAZOP Guide to Best Practice by Frank Crawley and Brian Tyler

- www.petrorisk.com

Certified Functional Safety Professional (FSP, TÜV SÜD), Certified HAZOP & PHA Leader, LOPA Practitioner, and Specialist in SIL Verification & Functional Safety Lifecycle, with 18 years of professional experience in Plant Operations and Process Safety across Petroleum Refining and Fertilizer Complexes.

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain