Industrial automation powers the efficiency and safety of processes in industries like oil and gas, chemical manufacturing, and petroleum refining. PLC and DCS are both indispensable in industrial automation, but they serve distinct purposes. PLCs are your go-to for cost-effective, discrete control in smaller setups, while DCSs are the backbone of large, continuous processes, offering scalability and reliability. By understanding their differences, you can choose the right system to optimize your plant’s efficiency, safety, and productivity.

What is a Programmable Logic Controller (PLC)?

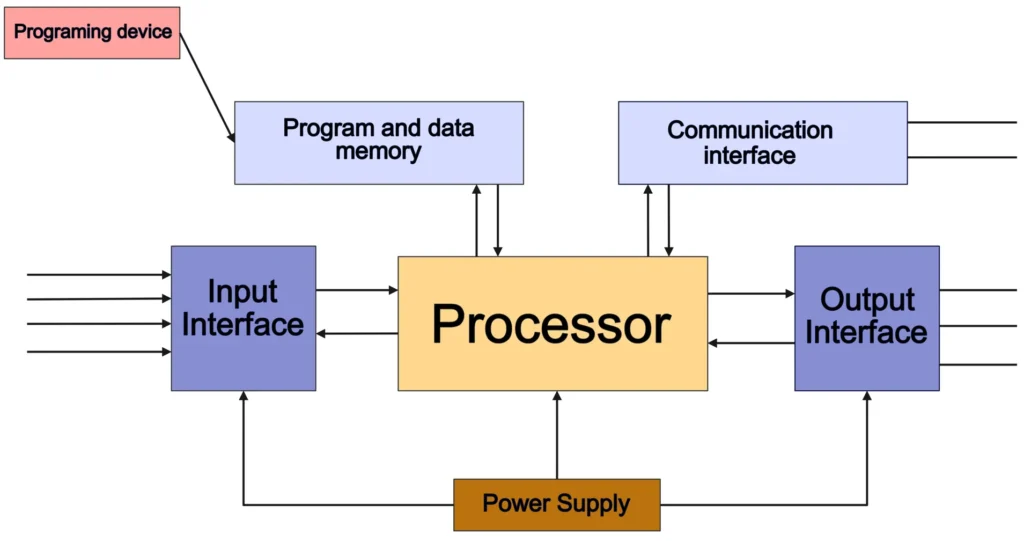

A PLC is a rugged, microprocessor-based device built to handle specific, often discrete, control tasks in tough industrial environments. It is a dependable workhorse that can withstand vibrations, extreme temperatures, and electrical noise. Originally developed in the 1970s to replace bulky relay-based systems, PLCs are now a cornerstone of automation, controlling everything from motors to safety shutdowns with precision.

Key Features of PLCs:

- Discrete Control: Excels at handling on/off tasks, like starting a pump or controlling a conveyor belt.

- Rugged Design: Built to endure harsh conditions, making it ideal for factories or small-scale plants.

- Programming Flexibility: Uses intuitive languages like ladder logic, function block diagrams, or structured text, mimicking electrical circuits for easy programming.

- Fast Response Time: Perfect for applications requiring quick, real-time decisions, such as robotic arms or valve sequencing.

- Modular and Scalable: Available in compact or rack-mounted designs, allowing flexibility for small to medium systems.

What is a Distributed Control System (DCS)?

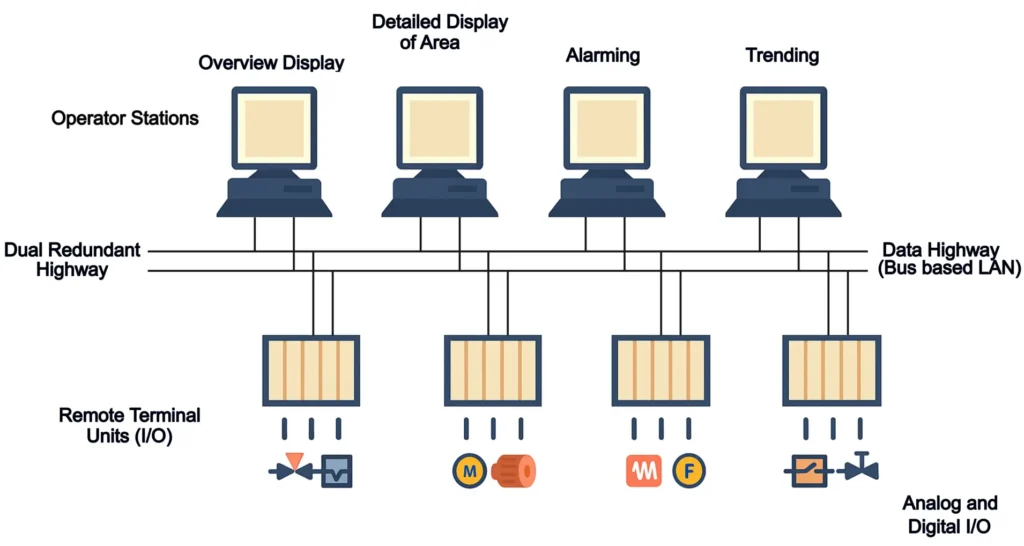

A DCS is a sophisticated, network-based system designed for large-scale, continuous processes. DCS coordinates multiple subsystems across a plant. It distributes control functions across various controllers connected via a high-speed communication network, often called a data highway, making it perfect for complex operations like those in refineries or chemical plants.

Key Features of DCSs:

- Distributed Architecture: Control tasks are spread across multiple controllers, reducing the risk of system wide failure.

- Continuous Process Control: Manages analog variables like temperature, pressure, or flow rates with precision, often using PID (Proportional-Integral-Derivative) control loops.

- Redundancy and Reliability: Built-in backup systems ensure operations continue even if one component fails.

- Advanced Interfaces: Offers operator workstations with real-time monitoring, alarms, and diagnostics.

- Communication Protocols: Uses protocols like OPC, Modbus, or Foundation Fieldbus for seamless integration with diverse equipment.

What are the applications of DCS in the Process Industry?

In a chemical plant, a DCS oversees the entire production process, from raw material input to final product output. It continuously monitors variables like reactor temperature and adjusts controls to maintain safety and quality.

Key Differences Between PLCs and DCSs

To help you understand which system suits the needs, let us compare PLCs and DCSs across critical aspects:

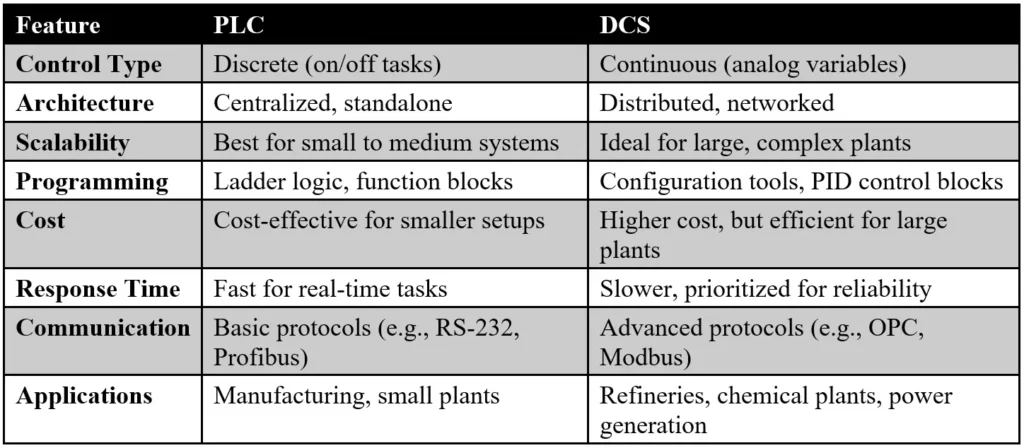

1. Control Type

PLCs shine in discrete control, handling binary operations like turning a motor on or off. For example, in a gas processing plant, a PLC might control a compressor’s start/stop sequence. DCSs, however, are built for continuous control, managing variables like temperature or pressure in a refinery’s distillation unit.

2. System Architecture

PLCs are typically standalone, with a centralized processor managing inputs and outputs, making them ideal for localized tasks. DCSs distribute control across multiple microprocessor units, which communicate via a high-speed network, ensuring coordination across large systems.

3. Scalability

PLCs are modular and flexible, perfect for smaller setups or dynamic systems where changes are frequent. Adding more PLCs for larger systems can be complex. DCSs, designed for scalability, easily handle large plants with many control loops, like in petrochemical refining.

4. Programming

PLCs use straightforward programming methods like ladder logic, which are intuitive for engineers familiar with electrical circuits. DCSs rely on complex configuration tools tailored for process control, requiring deeper knowledge of system dynamics.

5. Cost and Implementation

PLCs are generally more affordable, especially for small-scale operations like a water treatment plant. DCSs, while pricier due to their complexity, offer long-term savings in large plants through reduced wiring and maintenance costs.

6. Communication and Integration

PLCs use basic communication protocols for point-to-point connections, which can limit direct interaction between units. DCSs leverage advanced protocols like Modbus or Foundation Fieldbus for seamless integration, ideal for plants with diverse equipment.

When to Use PLC vs. DCS

Choosing the right system depends on your plant’s needs:

- Use a PLC for discrete, standalone tasks, like controlling a robotic arm in a car assembly line or a pump in a small gas processing facility. PLCs are cost-effective and flexible for smaller systems.

- Use a DCS for large-scale, continuous processes requiring coordination, such as managing multiple reactors in a chemical plant or overseeing a petrochemical refinery. DCSs excel in reliability and integration.

For example, in an automotive plant, a PLC might control a single welding robot, while a DCS oversees the entire assembly line, ensuring all stations work in sync. In a gas processing plant, PLCs could handle batch dehydration, while a DCS manages the overall process, reducing Reid Vapor Pressure variability from 0.43 to 0.26, showcasing its precision.

Can PLCs and DCSs Work Together?

Yes, in many setups PLCs and DCSs complement each other within a SCADA (Supervisory Control and Data Acquisition) system. PLCs act as local controllers for specific tasks, while the DCS coordinates broader process control, feeding data to a central SCADA station. For instance, in a refinery, PLCs might control individual valves, while the DCS ensures seamless operation across the facility, with data visualized through a Human Machine Interface (HMI) for operator monitoring.

What is SCADA?

SCADA stands for Supervisory Control and Data Acquisition. It is like the brain of industrial systems that helps monitor and control things like power plants, water treatment facilities, and manufacturing lines. It collects real time data from machines and sensors, shows it on screens for operators to see, and even allows them to control equipment remotely. Imagine keeping an eye on a whole factory from a single computer that is what SCADA does. It helps detect problems early, saves time, and improves efficiency.

Advantages and Limitations

PLC Advantages:

- Affordable for smaller systems.

- Simple to program and maintain.

- Fast response for real-time applications.

PLC Limitations:

- Limited scalability for large systems.

- Less robust redundancy compared to DCS.

- Not ideal for complex, continuous processes.

DCS Advantages:

- Highly reliable with built-in redundancy.

- Supports advanced functions like optimization and diagnostics.

- Ideal for large, integrated systems.

DCS Limitations:

- Higher cost and complexity.

- Slower response time for real-time tasks.

- Requires more expertise to configure.

Why PLC and DCS Matters for Process Safety?

In industries like oil and gas or chemical manufacturing, choosing the right control system impacts process safety, operational efficiency, and compliance with regulations. A DCS ability to manage complex, continuous processes reduces the risk of incidents, such as chemical spills or pressure surges. Meanwhile, PLC ensure precise control in discrete tasks, preventing errors in critical operations like valve sequencing.

References:

- Mehta, B. R., & Reddy, Y. J. (2015). Industrial Process Automation Systems: Design and Implementation. Elsevier.

- Lukas, M. P. (1986). Distributed Control Systems: Their Evaluation and Design. Van Nostrand Reinhold Co.

- Groover, M. P. (2000). Automation, Production Systems, and Computer-Integrated Manufacturing (2nd Edition). Prentice Hall.

- Bailey, D., & Wright, E. (2003). Practical SCADA for Industry. Elsevier Science & Technology.

- Petruzella, F. D. (2016). Programmable Logic Controllers. McGraw-Hill Education.

- https://inductiveautomation.com

- https://www.sciencedirect.com