Arab Heavy crude oil is a heavy, sour crude oil that is produced by Saudi Aramco, the state-owned oil company of Saudi Arabia. The main source of Arabian heavy crude oil is the Manifa oil field, which is located in the Eastern province of Saudi Arabia, in the Persian Gulf. The field was discovered in 1957 and it’s one of the major oil fields in Saudi Arabia, with an estimated production capacity of 900,000 barrels per day.

In addition to the Manifa oil field, there are also other sources of Arab Heavy crude oil in Saudi Arabia, such as the Berri and Abu Safah fields, which are also located in the Persian Gulf. These fields are considered to be of lower quality than Manifa crude oil and have a higher sulfur content, typically 3~4%.

The price of Arabian heavy crude oil is ~ 5 USD lower than Brent Crude and varies accordingly as the prices of crude change in the international market. The current price of Arab Heavy crude is 82.48 USD and that of Brent crude is 87.47 USD.

The Arabian Heavy Crude oil has high sulfur content, typically around 2.9~4% weight which makes it less desirable than other crude oil grades. Due to its high sulfur content, high residue share and high acidity, Arab Heavy crude oil requires more extensive and expensive refining processes to produce finished products such as gasoline and diesel. The refining process also produces higher emissions and pollutants, which can have negative effects on the environment.

Despite these challenges, Arab Heavy crude oil is still a significant source of revenue for Saudi Arabia and it is still traded in the global oil market. It is typically sold to refineries that have the capability to handle heavy, sour crude oils. These petroleum refineries are typically equipped with specialized processes, such as coking and hydrocracking, to convert heavy crude oil into lighter products like gasoline and diesel.

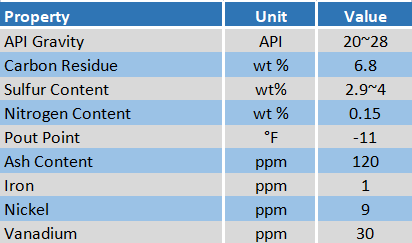

Additionally, it has to be blended with other crude oil types to reduce the corrosivity and viscosity before transporting it. The arab heavy crude oil has specifications that distinguish it from other crude oil grades but some properties vary depending on the source field. Here are some of the key properties of Arabian Heavy crude oil;

1.0 Density: Arab Heavy crude oil has a high density, typically around 900 kg/m3, which is higher than other crude oil grades. This means that it has a higher proportion of heavy hydrocarbons, such as asphalt and wax, which give it its high density.

2. Viscosity: Arab Heavy crude oil has a high viscosity, meaning that it is thick and flows slowly. This is due to its high proportion of heavy hydrocarbons, which can make it difficult to transport and pump.

3. Sulfur content: Arab Heavy crude oil has a high sulfur content, typically around 2-3% weight. This makes it a sour crude oil, which can have negative effects on the environment during refining.

4. API gravity: Arab Heavy crude oil has low API gravity, typically around 20-28 API, which is lower than other Saudi crude oil grades. API gravity is a measure of the density of crude oil, with higher API gravity indicating a lower density and lighter crude oil.

4. H2S and Mercaptans: Arab Heavy crude oil also contains high levels of hydrogen sulfide (H2S) and mercaptans, which are both highly toxic and corrosive gases. These compounds can make the crude oil more dangerous to handle and transport, and they need special treatment during refining.

5. Pour Point: The pour point is the temperature at which a fluid will no longer flow. Arab Heavy crude oil typically has a high pour point, due to its high viscosity and a high proportion of heavy hydrocarbons.

6. Corrosivity: Corrositivty is measured by the salt content and acidity of crude oil. Arab Heavy crude oil is highly corrosive due to the high sulfur, salts and acidity content, which can cause damage to equipment and facilities.

7. Metal content: Arab Heavy crude oil typically contains high levels of metallic impurities, such as iron, nickel and vanadium These metals can significantly clog the catalysts in petroleum refineries.

Top References

- Petroleum Economics and Engineering Edited by Hussein K. Abdel-Aal Mohammed A. Alsahlawi

- www.oilprice.com

For further information, discussion and queries please comment in the box below or contact us at admin@ or follow us on Facebook & LinkedIn.

Certified Functional Safety Professional (FSP, TÜV SÜD), Certified HAZOP & PHA Leader, LOPA Practitioner, and Specialist in SIL Verification & Functional Safety Lifecycle, with 18 years of professional experience in Plant Operations and Process Safety across Petroleum Refining and Fertilizer Complexes.

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain

- Nasir Hussain