The vacuum distillation unit is designed to process the reduced crude from the atmospheric crude distillation tower bottom in the presence of a vacuum. The Vacuum Distillation Unit separates the reduced crude into light, medium, and heavy vacuum gas oil streams. All of the streams are further processed in hydrotreating, hydrocracking, or other downstream residue upgrading units to produce more valuable lighter products. This method is used to enhance the recovery of middle distillate products from the reduced crude.

The reduced crude is firstly heated in a furnace and then flashed in a vacuum distillation tower at a pressure much lower than atmospheric pressure. The vacuum distillation unit works on the principle that the residuum feed boils and separates under vacuum at a lower temperature without thermal cracking or degradation of the original hydrocarbons present in crude oil.

Further, vacuum lowers the boiling point of the mixture, as the pressure is lowered the boiling point of the material is decreased. Without, a vacuum for gas oil separations much higher temperature would be required that will crack the hydrocarbon materials. The VDU bottom or vacuum residue is sent to fuel oil blending or Asphalt bitumen production unit or further treated by thermal cracking or catalytic cracking by applying any of the Bottom of barrel upgradation methods.

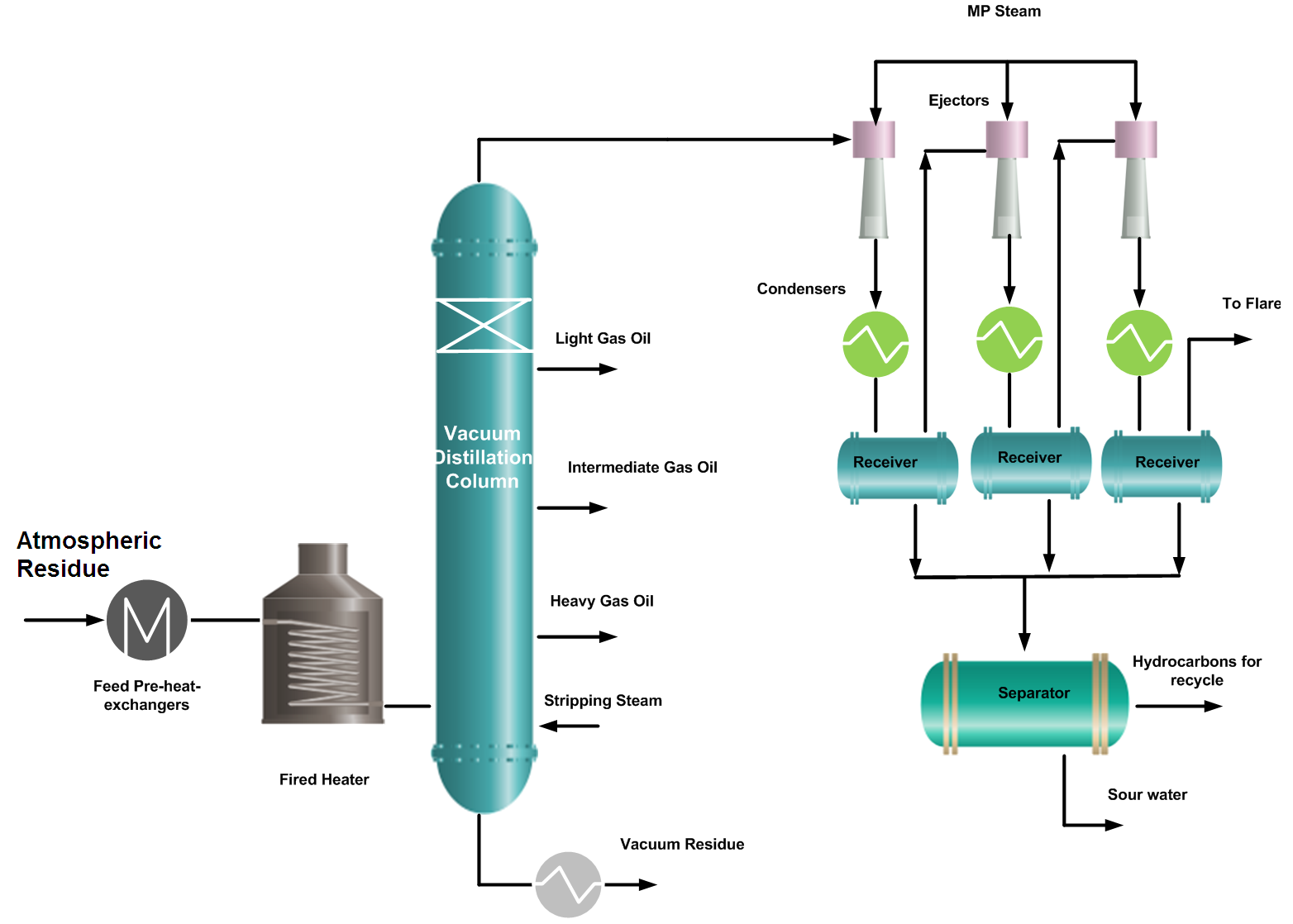

Hot atmospheric residue from the bottom of the atmospheric distillation column is sent after heat exchange with crude preheat exchangers. Then the feed is pumped through a series of heat exchangers and preheated by pump-around and hot products of the vacuum distillation unit. The residue can also be taken from storage but its temperature must be above 150 °C to avoid line blockage. The preheated feed is then passed through a heater for final heating to 370~420 °C.

To minimize cracking and coking, steam is also injected into the heater tube and passes at a controlled rate. The feed then enters the vacuum tower and flashes at the lower part of the column with multiple trays under vacuum conditions.

The vacuum distillation column has packings for fractionation and heat exchange zones. This reduces the pressure drop in the column which is necessary for a low vacuum in the lower section of the column. The bottom zone of the vacuum column is equipped with valve trays. The vapors from the flash zone pass through a fractionation zone where the heavy ends are condensed with HVGO reflux. More up in the vacuum column, sections are split up by sprays of liquid from the pump around or the internal reflux streams.

The vacuum is applied and maintained by steam ejectors by using medium pressure superheated steam as the motive fluid. The ejectors along with medium pressure steam entrain the hydrocarbon vapors from the tower top, which are condensed in cooling water condensers.

Usually, three numbers of ejectors are applied the first stage sends the un-condensed vapors are sent for condensation. Some parts and steam are condensed and the un-condensed vapor then enters the second stage followed by condensation. The uncondensed vapors from the second stage go to the 3rd stage where after condensation the uncondensed vapors are finally vented out through a flare, a stack, or incinerated in a fired heater. The condensed vapors and steam are collected in a condensate receiver, where water and hydrocarbons are separated. Water is further sent for treatment in the sour water treatment section and light hydrocarbons are recycled as a Light Slop.

A vacuum of 25–40 mm of mercury is maintained at the top of the column and 90–120 mm at the bottom, depending upon the design. Condensates from these ejectors are collected in a drum, known as a hot well.

Normally, 2~5 types of products are received from the vacuum distillation column. But mainly three products Light, Intermediate, and Heavy Gas oils are obtained from the vacuum column. A few plates below the top plate of the column, light gas oil (LVGO) are drawn. The next oils drawn below the light gas oil tray are intermediate and heavy gas oils as shown in the PFD of the vacuum distillation unit. The products of VDU are further processed to convert them into more desired costly products. The vacuum distillation unit products and their uses are as follows;

| Vacuum Products | Typical Uses |

| Light Vacuum Gas Oil (LVGO) | Hydrotreating, Hydrocracking feed, Fuel Oil Blending |

| Intermediate Vacuum Gas Oil (IVGO) | Hydrocracking, De-asphalting unit, Lube oil production |

| Heavy Vacuum Gas Oil (HVGO) | Hydrocracking, lube oil production, De-asphalting unit, Visbreaking for fuel oil production |

The bottom residue from the vacuum distillation tower is called the short residue (SR) or vacuum residue, which is stripped by the bottom steam followed by cooling through a steam generator and sent to the deasphalting unit or visbreaking for further processing.

A portion of the hot vacuum distillate is drawn from the column and returned back after cooling to control the heat load of the column. This stream is called the pump-around which is the only stream compared to circulating refluxes in the crude distillation column.